Cloud-based milk analyzers are developed to address the lack of transparency and inaccuracy in milk quality testing methods.

But do we really need IoT based milk analyzers?

The dairy industry significantly contributes to India’s economy. India is still untouched by the concept of “being vegan.” This is a reason why a very large amount of the population is dependent on animal husbandry for income.

However, milk is a perishable liquid as it is produced in small quantities and a scattered manner, so meeting a huge population demand becomes very challenging.

Moreover, problems like adulteration and farmers not getting enough value for their products are still a concern. And an IoT based milk analyser can solve all this and several other issues in the animal husbandry industry.

If you run a dairy business or are in any way related to the dairy industry, then this blog about IoT dairy farming and cloud based milk analyzers is a must-read for you.

What Is Cloud Based Milk Analyzer?

A cloud-based milk analyzer is a smart device that uses the Internet of Things and connectivity to analyze the composition of milk, allowing one to determine the milk’s quality. It is one prominent example of IoT dairy farming.

However, do not confuse a milk testing kit with a milk analyzer. Since this milk monitoring system provides much more than just milk testing.

In this smart milk analyzer using an IoT system, milk testing data is collected and uploaded to a secure cloud platform for further analysis, storage, and real-time data access.

Why is There a Need for a Cloud Based Milk Analyzer?

A few years back, to fulfill the dairy demands of Indians, Verghese Kurien brought the white revolution, by increasing the productivity of milk at that time. From facing acute milk shortages, India became the leading milk producer after the white revolution.

India ranks first in the global milk production market, contributing 24.64% of the global milk production.

Nonetheless, in the fiscal year 2022-2023, total milk sales in India were nearly 58 million liters. This was a decrease when compared to previous years.

It’s because animal productivity is lower compared to the global average.

Also, dairy farmers, when selling their milk in the collection centers, receive payment based on the fat content in the milk. However, the local milk analyzers can give incorrect readings or manipulate the readings.

Challenges that a smart milk quality analysis can solve

- Till now, the farmers have been paid on the basis of the FAT content in the milk. However, the milk procured may not meet the expected quality standards, resulting in increased processing costs.

- Non-cleaning of the machines can also lead to deviations in milk analyzers, resulting in an erratic reading of FAT and SNF.

- Furthermore, manual calibration of milk testing equipment can increase the possibility of malpractice because there are no historical logs of actual calibrations.

- Additionally, because the calibration is done manually, farmers have no assurance that the machine is providing accurate milk parameters.

To overcome these challenges, a prompt solution is designed, namely, an IoT based milk analyzer.

How the Cloud Based Milk Analyzer Works?

The smart milk monitoring system is based on IoT technology. Here’s the breakdown of how it works:

- The milk analyzer here itself is a piece of hardware that takes a milk sample.

- It uses ultrasonic sensors to measure the milk’s composition. Milk composition typically includes:

– Fat content

– Solids-Not-Fat (SNF) like proteins, lactose, and minerals

– Presence of added water

– Milk density

– pH of milk - Cloud integration is done to connect the device to the internet. This allows the transmission of milk data to a cloud platform.

- The cloud-based analyzer offers online calibration. This will eliminate manual calibration, thus reducing errors, and will give consistent readings.

- The milk analyzer system also comes with mobile app integration. So, farmers get access to milk analysis reports and can track trends on their phones.

Some of the Features of an IoT-based Milk Analyzer

The features of a smart milk quality analysis system are:

1. Accurate Reading

With the cloud based milk analyser, you get an accurate percentage of FAT, SNF, and water proportions along with milk density in single testing.

2. Remote Access

The users or authorized personnel can access milk-quality data from anywhere with a stable internet connection. This feature is beneficial for the quality control team at processing plants or the managers who oversee multiple centers.

3. Data Sharing

Milk quality data can be securely shared among the relevant buyers.

4. Online Calibration

The system offers secure online calibrations, preventing any human interference. Thus, farmers get the right price for their milk.

5. Easy operations

The cloud-based milk analyzer doesn’t require much effort to get acquainted with its operations, cleaning, and calibration.

Benefits of Using a Cloud-Based Milk Analyzer

Some more reasons of using a cloud-based milk analyzer are:

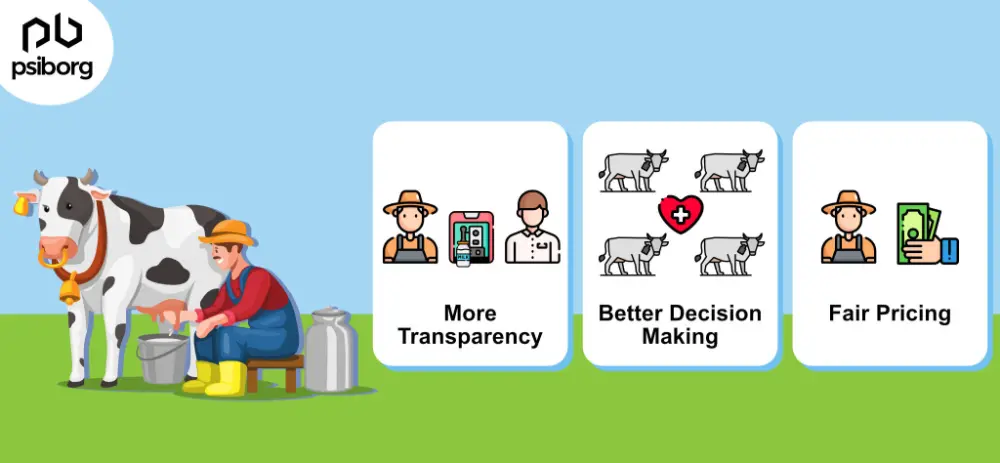

1. More Transparency

The smart IoT solution provides a clear picture of milk quality for both farmers and processing staff.

2. Better Decision Making

It’s the data-driven insights that help the farmers in determining and improving their herd’s health and production practices.

3. Fair Pricing

Accurate milk quality analysis will make sure that farmers get fair pay based on the quality of the milk.

In addition, the smart IoT solution ensures improved milk quality, which leads to an improvement in the quality of dairy products with high added value.

By eliminating manual calibration practices, we can also eliminate the extent of malpractice by controlling variability in the SNF.

The cloud-based milk analyzer also helps farmers make decisions and improve the feeding of cows.

The quality and quantity of feed consumed by the cows has an impact on milk quality. As feeding is the most expensive aspect of dairy farms, optimized feed control is required. With the help of a smart milk quality monitoring system, farmers can maintain optimal feeding regimes, recognize the effects of ration changes, and also detect reduced feed quality.

To end this,

PsiBorg offers IoT solution development and PoC to MVP development services.

Through our service, we build smart and innovative IoT dairy farming solutions like cloud-based milk analyzers for businesses that want to change the traditional milk quality testing methods and want to bring revolution to the dairy industry.

From cattle management to farm operations management, we create a variety of IoT-based monitoring and tracking solutions.

So, if you are interested, reach out to us, to get instant quotes.

FAQs

A cloud-based milk analyzer monitors 6 parameters to determine milk quality. These parameters are- fat, SNF, added water density, pH, temperature, and titrable acidity.

The list of sensors that are utilized in a cloud-based milk analyzer system are- pH sensors, enzymatic biosensors, temperature sensors, fat sensors, and more.

The best and most accurate way to detect milk adulteration is to use an IoT system. An IoT-based milk analyzer system uses a variety of sensors to determine the pH, fat content, and SNF value of the milk, which assists processing units in detecting milk adulteration.

The principle behind a cloud-based ultrasonic milk analyzer system is to measure the sound velocity through a milk sample. The milk analyzer system performs a quick analysis of milk quality based on fat, SNF, water, protein, and lactose levels.