How a Toilet Smell Detector Solves All Sanitation Issues?

The toilet smell detector detects the specific compound that releases the odor An alert is generated as soon as the concentration surpasses the predetermined threshold

Everything begins with an idea. Whether it is a pin or a pen, someone must have thought about the idea before launching the final product. Here the process of conception to an IoT product is known as the IoT Product Development Life Cycle. The IoT solution development lifecycle consists of both software and hardware development. We are all already aware of the software development life cycle, but the hardware part is still unclear. Although the hardware part of an IoT solution requires a complete understanding of the product, sensors, firmware, circuit design, etc. Let’s understand the stages involved in the development of an IoT solution.

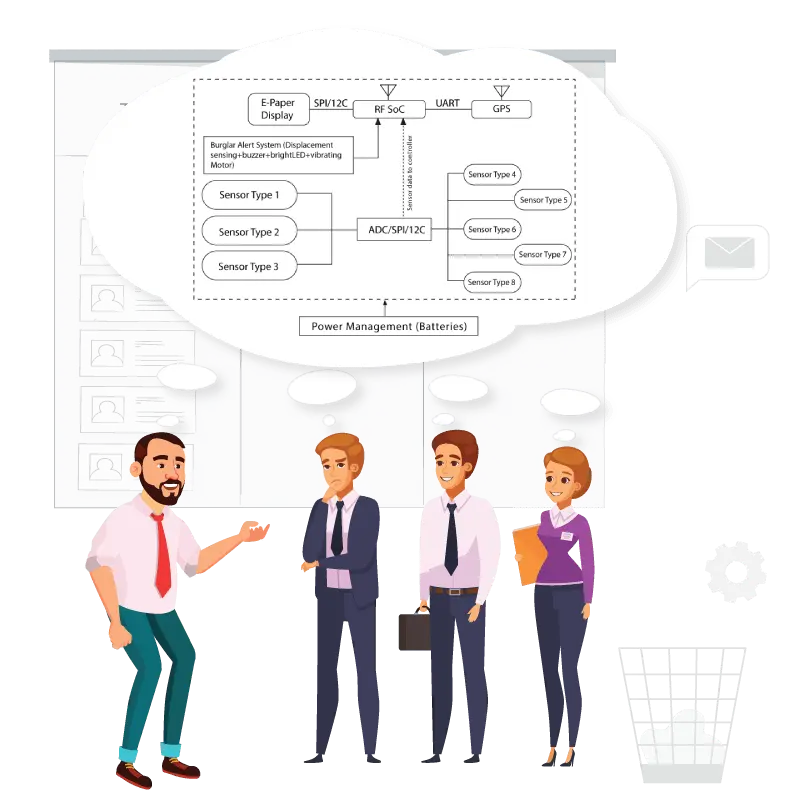

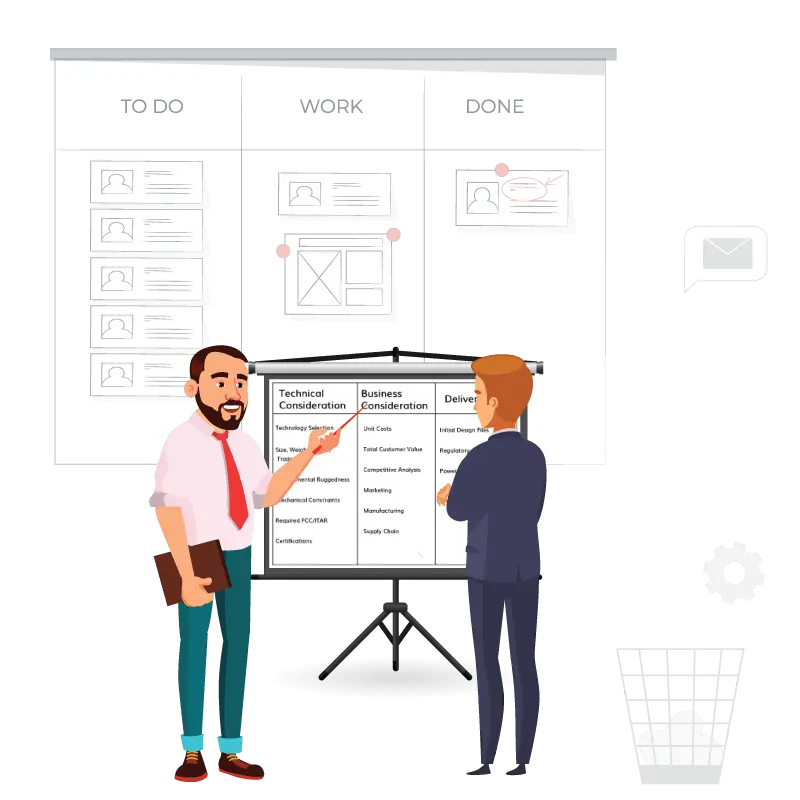

In an IoT life cycle, every project gets started with understanding and getting a list of precise requirements. Discussing the idea with the customer and gathering what he wants to achieve with the project is the initial step for the IoT device life cycle. The client is brainstormed with questions related to the project, considering power and size estimates, and a complete document is created for the requirements. After understanding the idea and gathering the requirements, we analyze the possibility of the project. The functional requirements are given after considering the realm of possibility and then a strategic plan is created for the IoT development process.

Soon after gathering the requirements, the next phase of IoT system is to design an IoT prototype. A team of engineers starts transforming the idea with specific technologies, software, circuit design, algorithms, and other essential component to develop a prototype. In this step, the right connectivity solution for your IoT product is identified, based on the go-to-market strategy. A walkthrough of cost, battery life, range, and other important factors is given in the built prototype, which helps the client determine which solution will work with the final product. Everything from the ratio of cost/ performance to solutions to the designers’ challenge, is discussed.

Throughout the project, schematics, layouts, software algorithms, and mechanical aspects of the product are reviewed from time to time. It is a crucial stage, as the product’s reliability in the future depends on reviewing the loopholes and making it feasible to use in critical conditions. It is important to review the IoT prototype throughout because it helps improve the manufacturing and performance of the product. It also reduces the project cost. The project review phase not only helps in the development phase but also helps in making the product user-friendly.

The Proof of Concept in IoT shows how the final product would function with the optimal combination of hardware and software . The prototype of the actual product is built during this phase. Embedded boards, development kits, sensors, simulators, modules, etc. are tested with the firmware written. In the journey till today, we have created modules that help us with rapid prototyping. The prototype is developed keeping in mind the targeted form factor, cost/performance ratio, and design of the enclosure body for the product. The process of IoT prototyping includes various stages and is done several times till the desired prototype is made without any errors.

After the IoT prototype is complete, the next step in the IoT life cycle is to test it with various conditions and validate it with its software application and server. The prototype and the IoT mobile application or web application are validated before taking it forward for manufacturing processes. The different parameters of the hardware, such as signals, voltages, amplitudes, magnitudes, temperatures, heat conditions, power consumption, etc., are tested. The final prototype is the one that the client approves for manufacturing. At the end of this stage, the delivery of the prototypes, design files, test reports, estimates, and a detailed set of future recommendations is done.

The product prototype is tested over the assembly line to make the product a success. The manufacturing of the product can be done for bulk products. The test such as stress testing, defects identification, individual components testing is performed for the product. After the issues are identified, the reason for the problem is checked, and the rectification of the problem is done. The final prototype is given for manufacturing .

The development of the product is marked complete at this stage. Now the final phase in IoT life cycle, the maintenance part starts. The product needs modifications from time to time to remain up to date with the technologies. The engineers and programmers provide maintenance throughout the product lifetime. You developed the product and now new updates, versions, products with added features, etc. can be enhanced regularly. The firmware updates in IoT devices are provided, and new features are updated every now and then through FOTA. At this stage, the challenge of building an IoT solution is conquered.

This is how a IoT product development process goes like, which involves a knowledge of wireless protocols, firmware development, hardware design , IoT cloud and device integration along with experience in product designing.

Looking for IoT solutions development for your innovative ideas? If yes, then you have landed on the right destination. When it comes to providing the best end-to-end solutions for IoT development, PsiBorg Technologies shines the brightest. We follow the exact IoT development process as explained above and make sure that every stage is perfect before moving to the next stage. You can rely on us for everything which is needed in IoT development as we have collaborated with different trustworthy vendors providing various services. So, what are you waiting for, connect today!

The toilet smell detector detects the specific compound that releases the odor An alert is generated as soon as the concentration surpasses the predetermined threshold

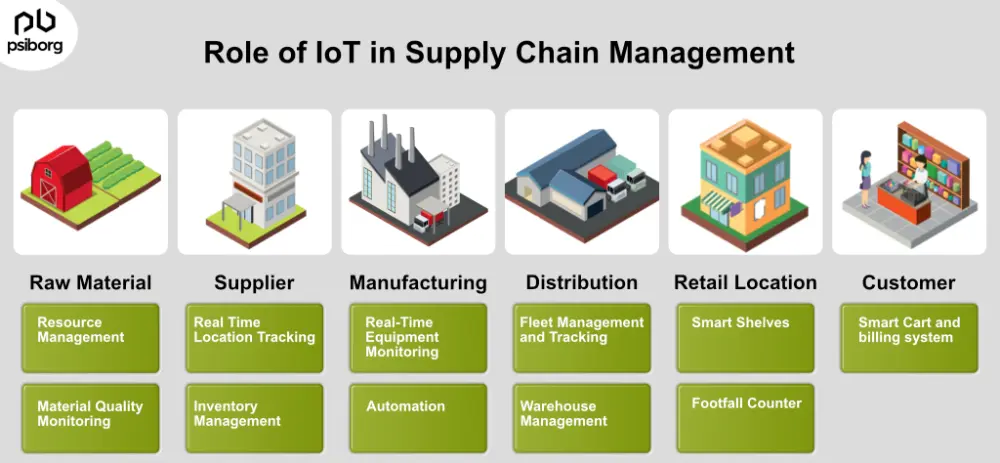

IoT in supply chain management automates and streamlines everything from raw material collection to product distribution

A cloud based milk analyzer is a smart device that uses the Internet of Things and connectivity to analyze the composition of milk thus determining