A supply chain is considered the backbone of a nation’s domestic and global trade. This is the reason why there is continuous advancement in the field of supply chain management. One such recent advancement is the use of IoT in supply chain management.

The use of Internet of Things technology has begun to have a positive impact on the supply chain by improving connectivity and providing businesses with more control.

The primary objective of using IoT in the supply chain is generally tracking and monitoring.

If a minor delay or deviation occurs in the entire supply chain, the entire logistics and supply chain system gets disrupted.

The more the population grows, the more trade increases, and the more complex the supply chain becomes. The challenges for logistics companies are also becoming more complicated. Today, it is primarily about meeting consumer demand, increasing delivery speed, and optimizing operational efficiency.

So let’s discuss the use of IoT in supply chain management (SCM), its benefits, and its major roles.

Understanding supply chain management

Traditional logistics and supply chain operations involve tracking good movement and material safety, literally blindfolded. There was a lack of transparency, real-time visibility, and automation. Plus, manual data entry and paper-based documentation slow the entire operation.

Here, when I talk about traditional methods, I mean the age-old methods. Things have definitely changed in recent years, and this is clearly visible.

We, Gen Z and the millennials have witnessed the evolution of the logistics industry — 1-week delivery has become same-day delivery. From not receiving any information about the delivery to receiving real-time delivery status, progress has been made.

This shows that businesses in the logistics and SCM industries have already started adopting IoT for their revenue growth.

If you are new to the logistics industry or have yet to use IoT to improve business operations, this blog will help you understand the importance of IoT in today’s world and provide you with appropriate IoT solutions for your business.

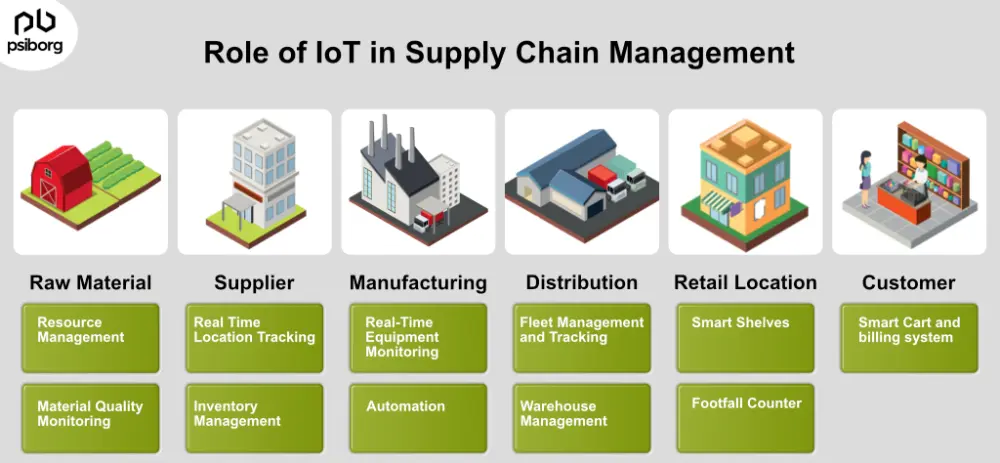

Role of IoT in Supply Chain Management

Consider running a supply chain in which your staff manages the entire supply chain and is aware of where all of your goods are in their condition, and their destination in near real-time. Well, you also know that a human can’t remember all of this.

Here, the staff we are talking about is IoT. All of this is only possible by installing an IoT system.

Still confused? Let me explain how it works:

The IoT sensors installed throughout the supply chain collect data on the location, condition, and movement of goods via IoT data collection.

The collected data is transferred through a communication network to the centralized platform.

Then, the data is aggregated on the centralized platform, and all the incoming data is compiled into a single dataset.

This organized data is then categorized into a structured repository of information.

After that, the data is analyzed and used to optimize all the supply chain aspects, such as warehouse management, logistics, and demand prediction.

The types of smart IoT devices that are generally used in supply chain management are:

- RFID (Radio Frequency Identification) tags

- GPS (Global Positioning System) trackers

- Temperature and humidity sensors

- Smart shelves and containers

- Near-field communication devices

The major role of IoT in supply chain management is tracking, monitoring, and analytics.

Benefits of IoT in Supply Chain Management

Let’s have a look at some of the major benefits of integrating IoT in SCM.

1. Real-time Data Insights

The major reason for using IoT in logistics and supply chains is its ability to collect and analyze data in real time using smart, specialized sensors. The supply chain industry can utilize this real-time data to collect information related to delays in deliveries and more.

Moreover, by getting real-time data on stocks and their condition, the supply chain managing team can quickly act on any changes in the order status.

2. Improved Efficiency

IoT brings automation, and by automating supply chain tasks like inventory tracking and maintenance scheduling, businesses can streamline processes and reduce manual labor. This leads to higher efficiency throughout the entire supply chain.

3. Cost Reduction

The IoT system will help staff identify operational inefficiencies that the human eye may miss, as well as areas for optimization, resulting in cost savings in areas such as inventory management, maintenance, and logistics.

4. Enhanced Decision Making

By getting real-time data and analytics, supply chain managers can make more informed decisions regarding inventory levels, production schedules, and shipment routes, thus improving overall performance.

5. Increased Transparency

With IoT solutions, managers can track the movement of goods from production to delivery across the entire supply chain. This transparency helps build trust among partners and improves accountability.

6. Better Customer Service

By getting real-time shipment data, timely delivery of products is ensured. In addition, predictive maintenance can reduce stockouts and improve product quality. This also results in higher customer satisfaction and maximum customer retention.

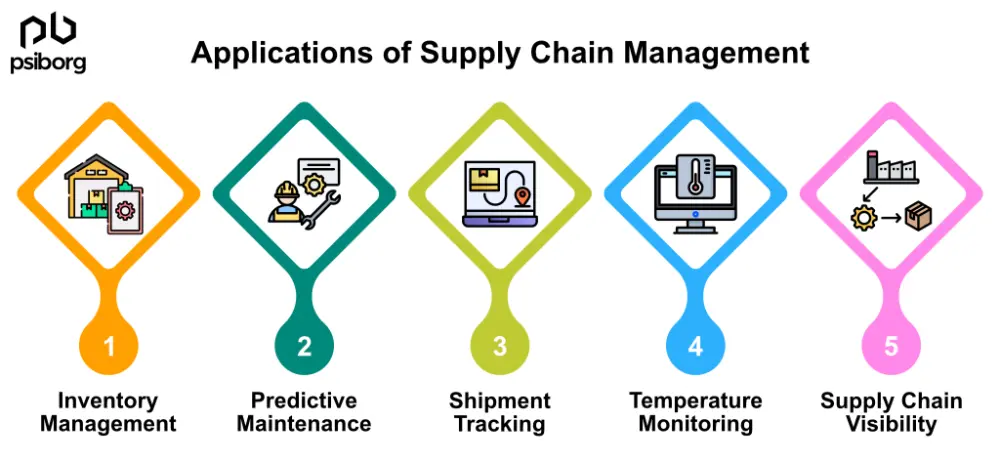

Applications of supply chain management

Looking at the range of benefits that IoT offers in the SCM industry, it’s quite evident that it can be used in various forms across various areas. However, some of the major applications of IoT-based supply chain management solutions are:

1. Inventory Management

This ability of IoT to track anything’s location in real time can also be utilized to manage inventory. The use of IoT based inventory management systems will greatly simplify the audit process of inventory items.

For a supply chain business, inventory management is involved, deciding what goods are out of stock and which are available at the moment. All this inventory-related information keeps getting updated thanks to smart devices.

2. Predictive Maintenance

The use of IoT in supply chain management is considered business-friendly because of its predictive maintenance ability.

The IoT system uses current and historical data collected from various sensors to make an informed prediction about the health and utilization of the equipment used in the supply chain.

The smart system can also predict the possibilities of failures, helping the management team to act accordingly. So, with the use of IoT-based predictive maintenance systems, operational downtime can be reduced and the productivity of the entire operational chain can be increased.

3. Shipment Tracking

The use of geolocation is always effective in tracking and getting status updates on transported goods and raw materials. By using GPS tracker, one can get reliable and accurate location data that will help the supply chain managers know about the whereabouts of trucks, products, and raw materials. It’s the use of IoT technology that makes it possible for us to track our parcels, their estimated delivery time, and date.

4. Temperature Monitoring

Most of the products stored in warehouses are raw materials that need to be continuously monitored so that they don’t get spoiled or damaged.

To prevent these kinds of disasters, warehouses inside the supply chain install temperature and humidity monitoring systems. So if any of the parameters deviates from the predetermined threshold, the quality of the product is rechecked. Temperature monitoring is a part of IoT based storage condition monitoring that is utilized to maintain proper conditions inside the warehouse.

5. Supply Chain Visibility

Throughout the stages of the supply chain, from product manufacturing to retail, the company uses IoT devices to collect data on areas influencing the quality and timely delivery of products. Additionally, businesses use IoT in manufacturing industry to optimize and improve the accuracy of goods pickup and material handling.

PsiBorg’s Shipment Tracking Solution for Supply Chain Management

We at PsiBorg assist industrial businesses by developing smart IoT solutions. One of the solutions that we have developed for the logistics and supply chain industry is a “shipment tracking solution.”

We have developed a shipment tracking system using interconnected devices and sensors to monitor the speed, location, object orientation, and various other parameters of goods in transit.

The system not only improves real-time location tracking, but it also makes it easier to resolve related issues quickly and make informed decisions.

The list of features that we offer through our shipment tracking solution are:

- Increased visibility into shipment’s status and location.

- Improved operational productivity through automated processes.

- Better customer service with accurate delivery estimates and updates,

- Continuous monitoring reduces the risk of theft and loss.

- Proactive issue resolution through early detection of problems

- Simplified operations with optimized routes and resources

- Improved inventory management with real-time tracking

- Provides comprehensive insights for data-driven decision-making.

To learn more about how our shipment tracking system works, please read our case study or contact us directly so we can discuss the solution.

FAQs

IoT in supply chain management is used to improve and streamline the entire supply chain, from raw material collection and production to product distribution. The primary reason for integrating IoT in supply chain management is for tracking, monitoring, and analytics.

The integration of IoT in Supply Chain Management enables real-time tracking of product location and status from anywhere, whether inside the warehouse or outside during transportation. Aside from tracking, IoT is used within the supply chain to automate processes, collect real-time data for analysis, and improve decision-making.

The various use cases of IoT in the supply chain are:

Real-time inventory tracking, condition monitoring such as temperature and humidity, route optimization, increased transparency, and process automation for efficiency and accuracy.

IoT in supply chain management (SCM) provides improved transparency, asset tracking, predictive maintenance, streamlined processes, cost savings through automation, and optimized inventory management, which leads to increased efficiency, responsiveness, and customer satisfaction.