With the ongoing Industry 4.0 revolution, there have been some noteworthy technological advancements that are making businesses more flexible, innovative, and resilient.

Today, we are leveraging technology in every single field, be it doing business, managing employees, selling products, doing marketing, or simply living.

What made things change like this?

Well, it’s the consumer’s interest and their demand for customization.

To be specific, one technology that has seen the most rise in recent years is the Internet of Things (IoT).

The Internet of Things (IoT) is the biggest step towards digital transformation today.

How can the manufacturing industry remain untouched by this digital transformation?

The integration of IoT in manufacturing industry is like taking a big step towards success!

Now, you might hesitate to take the big step, but we got your back. However, to implement IoT solutions in your manufacturing business, you first have to understand how IoT is used in manufacturing industry.

Let’s discuss why implementing IoT in manufacturing industry is a good idea and what are the best ways to do so.

MANUFACTURING INDUSTRY + IOT = INDUSTRIAL IOT (IIOT)

IoT is present all around us; all the interconnected devices, wearable watches, smart speakers, and smart TVs are all examples of IoT.

Manufacturing industries are adopting this digital interconnectivity and are applying it to their manufacturing operations. Some IoT in manufacturing industry examples are ground-level facility management, staff management, machinery monitoring, and much more.

However, the use of IoT in manufacturing industry is referred to as Industrial IoT (IIoT). And yes, IoT and IIoT are two different things.

IIoT (Industrial Internet of Things) can be seen as a subsection of IoT (Internet of Things).

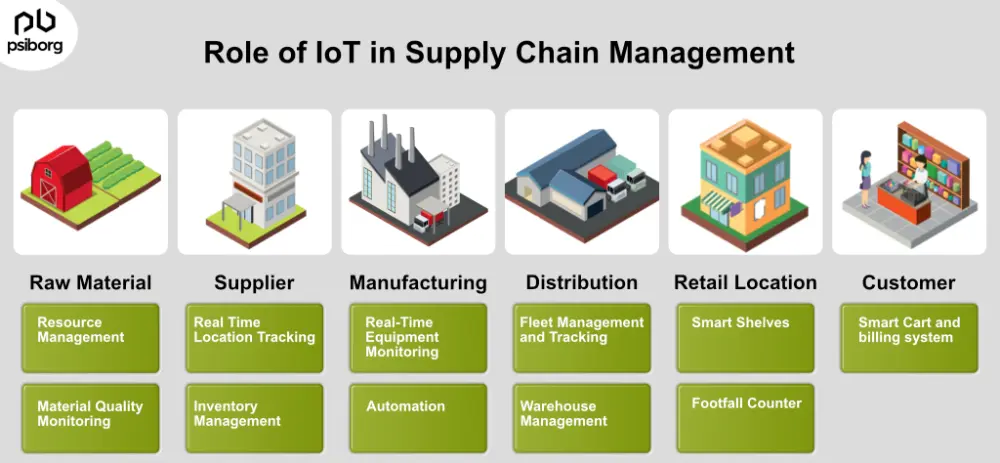

IoT is a user-centric concept, while IIoT focuses on supply chain, manufacturing, and management.

So, IIoT uses several digital tools to connect devices, data, and big machines in factories to increase productivity and improve quality.

In recent years, the use of IIoT in the manufacturing industry has increased twofold, as it’s making factories more safer for ground zero level workers, and yes, it has also helped businesses save millions of dollars.

According to the statistics:

The IoT manufacturing solutions market size will grow from $33.2 billion to $53.8 billion by the year 2025 at a CAGR of 10.1%.

- According to a report by PwC, 90% of manufacturers feel that integrating IoT into their production processes will bring long-term benefits.

- 35% of manufacturers collect and use data collected from smart sensors to improve the manufacturing process.

- 58% of manufacturers believe that the IoT will transform all industrial operations for the better.

So, this swing towards Industry 4.0 has brought noticeable changes to the manufacturing industry. Even the manufacturers are eager to adopt smart manufacturing techniques to move to a new level of success.

BENEFITS OF ADOPTING IOT IN MANUFACTURING INDUSTRY

Some of the biggest benefits of introducing the Industrial Internet of Things in manufacturing industry are:

1. INCREASED PRODUCTIVITY

The main reason to incorporate IIoT in manufacturing is to increase productivity. This is because the IoT automates the task. Thus, the robotics and automated manufacturing machines will work productively and precisely.

Also, sensors can be installed in big machines to monitor their performance constantly. This way, the managing team will have better and more real-time insights into the performance of all the equipment.

2. REDUCED ERRORS

IIoT can digitize and operate every part of manufacturing operations. By minimizing manual tasks, the manufacturers will also minimize the risks associated with human error. This will also reduce the risk of cyber-attacks and data breaches.

When the machines are connected, they will create an intelligent network that will communicate and coordinate with each other with the minimum amount of human intervention.

3. HIGHER MARGINS AND IMPROVED CUSTOMER SATISFACTION

With the use of IoT and connected devices, manufacturers can improve and maximize their present service delivery. Also, with remote monitoring using IoT, the team can receive early warnings and make quality improvements in future products. It will also help in building stronger bonds with customers, thus increasing customer satisfaction.

4. BETTER PLANNING AND SCHEDULING

By introducing IoT solutions, manufacturers can benefit from better planning and scheduling of workflows to increase product quality and yield. With industrial IoT solutions, businesses can experience better production planning, scheduling, and real-time monitoring of production lines.

Also Read: Impact of IoT in Leading Businesses

5 EXCITING USE CASES OF IOT IN MANUFACTURING

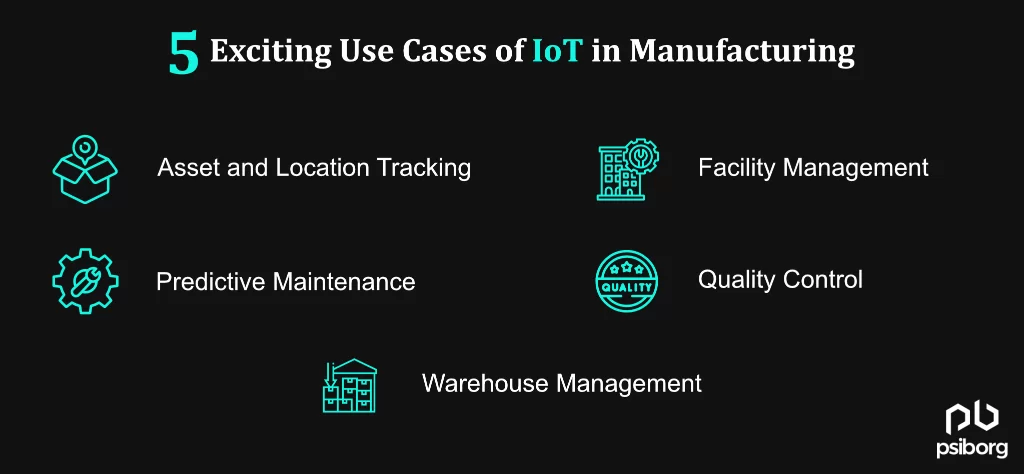

Now that we are familiar with the benefits of introducing IoT in manufacturing industry, let’s look at some exciting applications of IoT solutions:

1. ASSET AND LOCATION TRACKING

With an IoT-based asset tracking system, you can track and locate manufacturing products and deliverables in real-time. With an IoT system, the team can track all the goods in the supply chain to be updated about any possible damages to the goods.

2. FACILITY MANAGEMENT

The sensors connected to the IoT can monitor and manage environmental conditions such as humidity, temperature, and vibrations. This makes it easier to detect factors that hinder factory operations and alert the team when a fault occurs. IoT can also connect manufacturing machines to the internet, giving you constant insights into the machine’s performance.

3. PREDICTIVE MAINTENANCE

As mentioned above, getting real-time data from the connected IoT devices will help the team predict the shortcomings in machinery and tools. This will save a lot of time and increase the overall productivity. Plus, the cost associated with machine failures, repairs, and rework can also be reduced by a large margin.

4. QUALITY CONTROL

In the manual quality control process, manufacturers create a product, their quality control team tests it, and they hope to catch some flaws. IoT will make this process more proactive through thermal and video sensors that scan and collect complete product data throughout the stages of the product lifecycle.

With IoT support in quality control, manufacturers will have a stronger assurance of detecting quality problems.

5. WAREHOUSE MANAGEMENT

By integrating IoT technology into warehouse management, manufacturers can provide faster and quicker deliveries of their products, irrespective of their location. Manufacturers will gain supply chain transparency, prevent product damage and waste, and strengthen their inventory management system using IoT solutions.

To Conclude,

The Internet of Things in manufacturing industry holds very lucrative growth, and big enterprises are already exploring and adopting this technology to gain a competitive edge in the market.

IoT will ultimately become the promising technology that will drive the growth of the manufacturing industry and offer them ways to achieve manufacturing excellence.

The 5 use cases mentioned above are just the tip of the iceberg; there is more to IoT in the context of manufacturing.

We believe Industrial IoT will cater each and every step of manufacturing be it employee safety, security, surveillance, remote monitoring, product restocking, M2M automation, or inventory management.

Why are we so sure about this?

Because we make IoT solutions that solve issues faced by the manufacturing industry.

If you are in the manufacturing industry and want to grow at the speed of light, then look no further, because the IoT is sure to blow you away with its applications.

We are an IoT service-providing company that provides affordable and reliable industrial IoT solutions to help businesses.

Contact us to find out more about our experience and strengths in IIoT and how we can help you.

FAQ

The use of IoT in manufacturing sector is termed Industrial IoT (IIoT). One major benefit of using IoT in manufacturing sector is that it offers the ability to automate and boost operations. Automated machinery can work more accurately, thus boosting the productivity of the team and reducing downtime. Plus, IoT gives supply chain visibility to managers with accurate estimates of available materials.

Industrial IoT has completely transformed manufacturing operations. In the year 2023, the adoption of IIoT by manufacturers has risen, and it is expected to reach $397.86 billion by 2026 at a CAGR of 17.4 percent. It’s obvious from the stats that the adoption of IoT in manufacturing has increased, and it will continue to be like this because of the unmatched benefits it offers.

IoT gives benefits to all sizes of businesses. Small and medium-sized businesses can achieve a new level of productivity with IoT solutions. SMEs can use IoT devices, sensors, and actuators to automate, manage, and monitor plenty of business operations. Real-time remote monitoring, asset tracking, and inventory management are some areas where SMEs can switch to IoT to achieve success in their businesses.