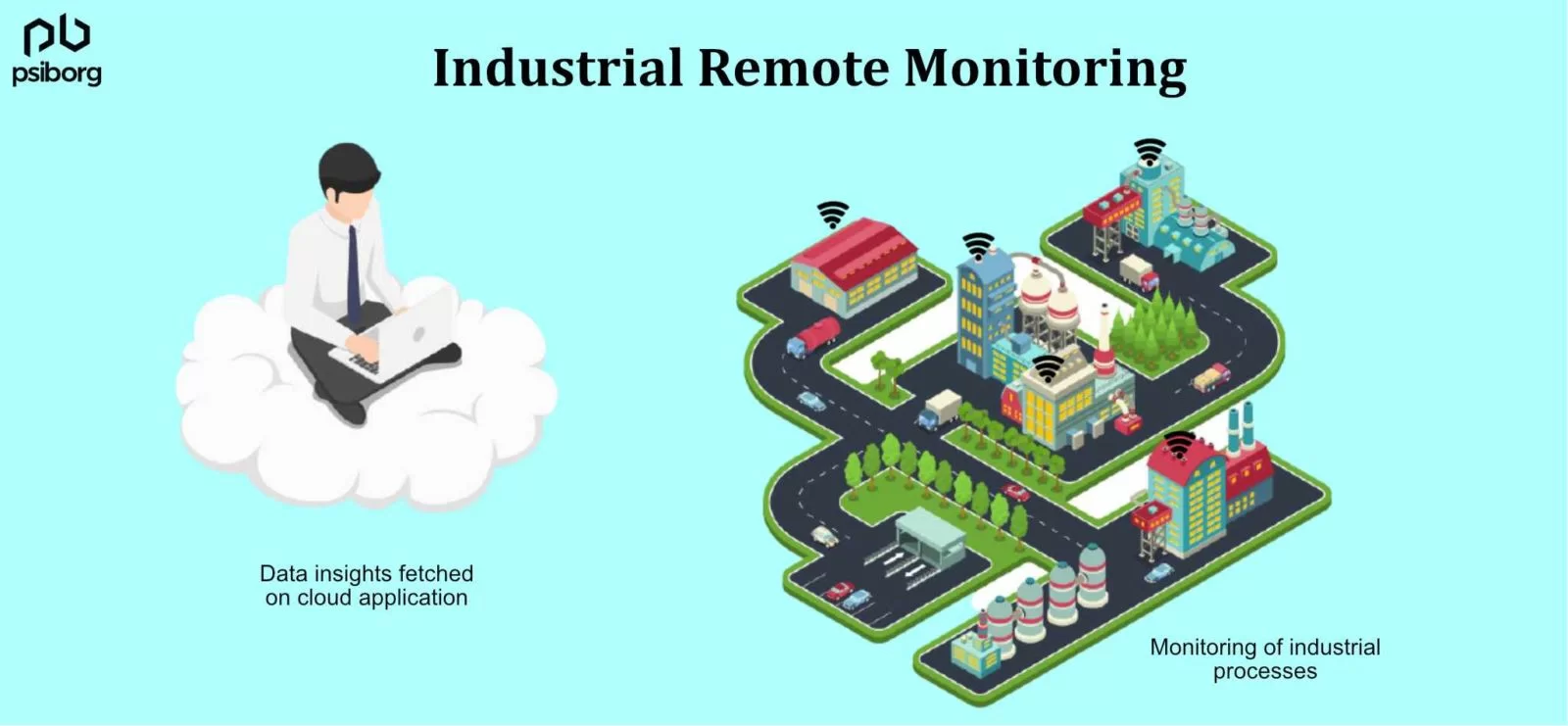

Remote monitoring is a popular application of IoT that utilizes machine and system data received from IoT sensors. In order to, provide accurate and valuable insights into how a particular system performs.

All industries can leverage IoT remote monitoring to be 24/7 informed on how a device is performing and operating. With IoT enabled remote monitoring, operators can monitor a large variety of equipment. Be it robotic assembly systems, motors, storage tanks, logistic equipment, and many more.

Moreover, above is a short description of IoT remote monitoring. Read below to get a detailed explanation of what remote monitoring in IoT is and what remote IoT applications are.

HOW DOES INDUSTRIAL REMOTE MONITORING WORK?

Industrial online remote monitoring uses IoT with the aim of collecting data about the operations/working of any given unit or machine.

Furthermore, this collected data is shown on the IoT dashboard, which can be in the form of tables, graphs, and other graphical representations.

The data is fetched in real-time and generates alerts in case of discrepancies. The IoT dashboard also shows historical reports and patterns.

The aforementioned reports and data insights enable engineers and industry supervisors to take corrective action at the appropriate time.

REMOTE MONITORING AND CONTROLLING OF INDUSTRY USING IOT

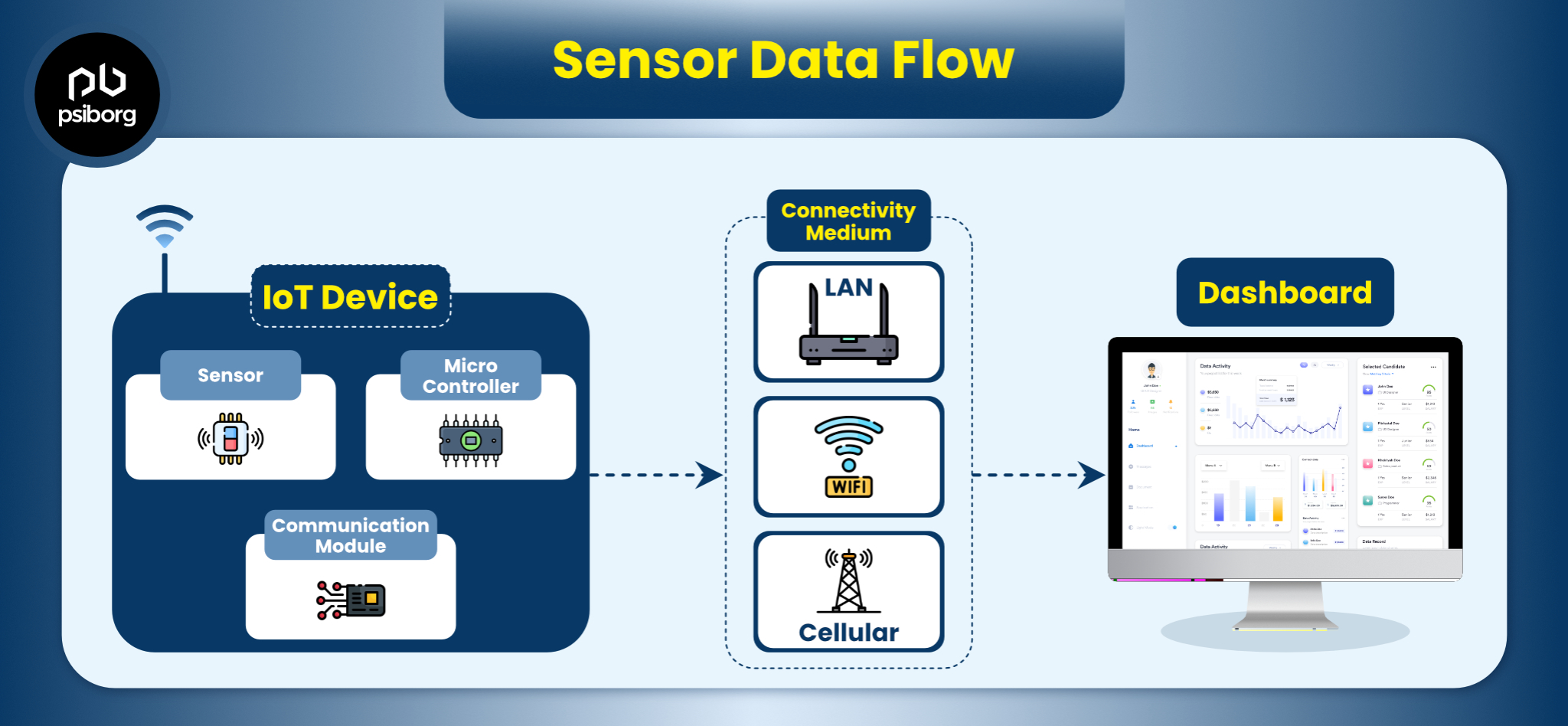

IoT Remote Monitoring solution consists of four main essential components.

Devices and Sensors – IoT sensor devices and Sensor Nodes are equipped with machinery that requires monitoring. This data consists of various parameters of the device to be monitored.

Connectivity Protocols – Online Remote Monitoring of IoT devices uses wireless connectivity protocols that enable communication.

IoT Platform – It is a Cloud platform that stores and manages the data fetched from sensor nodes.

Dashboard – The data on the monitoring devices can be seen by the supervisors on their PCs or mobile phones. The IoT dashboard is the dashboard where the data is represented in the form of graphs, also providing important insights on the monitored machinery.

IOT ENABLED REMOTE MONITORING

The Internet of Things fully leverages the capabilities of smart machines and deploys real-time data analytics. Thus, providing actionable insights from the data generated by the machines. Here’s more detail regarding remote IoT applications and how IoT has improved industrial remote monitoring.

- Smart machines are equipped with sensors and software that can track and collect data.

- Cloud computer systems are responsible for storing and processing this data.

- High-end data analytics systems derive useful insights from the data collected and relay these insights to engineers and industrial supervisors.

WHAT IS THE USE OF CONTROLLING DEVICES REMOTELY USING IOT?

There are various advantages of IoT remote monitoring, some of the remote IoT applications are as follows: –

REMOTE MONITORING INCREASES EFFICIENCY

The biggest benefit of IIoT is that it gives manufacturers the ability to automate, and therefore optimize their operating efficiency. Robotics and automated machinery with remote IoT data monitoring can work more efficiently and accurately, boosting productivity and helping manufacturers streamline their functions.

IoT enabled online remote monitoring systems empower manufacturers to improve operating efficiencies by:

- Bypassing manual tasks and functions and implementing automated, digital ones

- Making data-driven decisions regarding all manufacturing functions

- Monitoring performance from anywhere – on the manufacturing floor or from thousands of miles away

REDUCE ERRORS

Industrial IoT manufacturers to digitize nearly every part of their business. Therefore, by reducing manual processes and entries, manufacturers are able to reduce the biggest risk associated with manual labor—human error.

REDUCED COSTS

Knowledge is power, and the knowledge provided to manufacturers via IIoT solutions gives them the tools they need to reduce costs and generate more revenue. Data-driven insights into operations, production, marketing, sales, and more can steer businesses in a profitable direction.

IOT REMOTE MONITORING AND CONTROL

Controlling remote IoT devices in industries requires a combination of various technologies, which are as follows:-

FRONT-END EDGE DEVICES

These are multiple sensor-based IoT devices that collect data about the system that needs to be monitored. These devices are responsible for Sensor data collection. They must be secure and reliable.

CONNECTIVITY TECHNOLOGIES FOR IOT BASED REMOTE MONITORING

Remote IoT data monitoring in industries helps in solving many problems and can help in predicting faults.

It also sends alerts even if you are not present at the location.

WI-FI FOR REMOTE MONITORING IOT SOLUTIONS

Wi-Fi is a local area network (LAN). It provides internet access within a limited range, so it can be used for IIoT applications that run in a local environment. Although being a star network (where there’s one central hub with all nodes and devices connected to it), it’s easy to add or remove devices without affecting the rest of the network.

BLUETOOTH AS A CONNECTIVITY PROTOCOL

Bluetooth is a short-range technology that is cheap, but it does not work unless terminals are used within the same room as an access point. In an industrial IoT setting, Bluetooth works well if sensors are distributed nearly uniformly throughout an area (HVAC sensors, lights). But not so well for irregular deployments (power monitors, paper dispensers, industrial monitors).

CELLULAR NETWORKS FOR DATA TRANSMISSION

Cellular networks exist in most places, and they are managed by cellular network providers, making it an attractive option for IoT communication. Here, LTE-M and NB-IoT are two cellular systems used for IoT devices.

LOW POWER WIDE AREA NETWORKS

This technology, which includes LoRaWAN, Symphony Link, and Sigfox, among others, is ideal for connecting devices that send and receive small data packets over long distances while using very little power.

INDUSTRIAL IOT PLATFORMS FOR DATA PROCESSING AND ANALYTICS

To complete your system, you need an industrial IoT application or industrial Automation app software for analyzing the collected and transmitted data. The software also makes decisions and, in some cases, pushes commands back to controls at the edge.

USE CASES: REMOTE IOT APPLICATIONS

Online remote monitoring is a necessity in various fields where manpower is deployed to check processes in time intervals. This can easily be transformed into smart and can be monitored remotely.

REMOTE MONITORING OF YOUR MACHINES AND ELECTRICAL DEVICES

Sensors can be added to new or existing plants in order to monitor exterior parameters—like AC current consumption and vibration levels. Through a retrofit process to look for pumps that need maintenance or are approaching failure. Other examples include sensor-based monitoring of low voltage induction motors. Few more application of IoT based remote industrial monitoring is predictive maintenance of machines. IoT based predictive maintenance helps achieve more efficient use of existing industrial machines and equipment by enabling in prediction of machine failures. This helps in the reduction of maintenance issues. It can also help in identifying the causes of delays, whether they’re internal or external, this leads to reduced downtime and increased machine availability.

ENERGY CONSUMPTION MONITORING

The energy consumption monitoring platform is a growing area of use for IoT. With the help of this solution, there is a complete transformation in the way people and companies use and control electricity, electrical devices, loads and power storage. It consists of smart hardware, software and data tools. After installing the IoT based energy consumption monitoring system, a house, office building or any other facility turns into a smart space with more features and capabilities for power consumption monitoring and control.

With facilities for scheduling time for on and off appliances, you can save energy like never before.

SERVER ROOM MONITORING

IoT enabled server room monitoring systems help you closely monitor the ambient conditions in your server room to help you protect your critical server room assets from damage. Different types of ambient conditions, such as temperature and humidity monitoring in server rooms, power surges, water leaks, flooding, fire and smoke, and chemical material leakages can be monitored. However, this is achieved by carefully placing sensors in different server room equipment. With the help of IoT based server room monitoring systems, you can rest assured about the safety of your critical server room assets and uninterrupted data flows. Rack level temperature, ambient temperature monitoring, water and fluid leakage monitoring are commonly what server room monitoring consists of.

INSECT FARM MONITORING

Insect farming refers to the process of production of useful goods from insects. It includes activities like the rearing and breeding of insects. The survival of insects and their production yield requires that proper ambient conditions such as temperature, humidity, illumination be maintained. Insect farming requires close monitoring of temperature and other critical parameters for efficient control and maintenance which requires increased manpower and work times.

With the help of IoT, all the ambient conditions in insect farming processes can be monitored more closely and accurately in real-time. This is done by the use of temperature sensors, humidity sensors, light sensors etc.

FLEET MONITORING

IoT has revolutionized fleet monitoring through fuel use monitoring and savings, route optimization, driver monitoring, engine monitoring and preventive maintenance. This has resulted in greater efficiency of the fleet and greater savings. All of these can be achieved by using sensors and reliable wireless networks.

SOLAR POWER MONITORING

The IoT based solar monitoring system performs centralized remote monitoring and tracking of the real-time performance data of solar assets such as performance degradation, energy usage, downtime, losses etc causing generation loss.

Suggested Readings: M2M COMMUNICATION AND CONNECTED DEVICES

Challenges in IoT based Remote Industrial monitoring

- Cybersecurity threats

- Integration of Industrial IoT components such as sensors, radio, software, communication systems and protocols with existing operational technology in industries.

- High cost of IIoT

The future of Industrial remote monitoring is undeniably bright, as more R&D and investments are being made to integrate industrial processes with IoT.

Also Read: IoT in Logistics Industry, INTELLIGENT INDUSTRIAL REMOTE MONITORING APPLICATIONS

PsiBorg, an IoT solutions Development company , specializes in providing industry-leading solutions for industrial remote monitoring using IoT.

FAQ

Remote monitoring using IoT applies data from the sensors to the system to provide accurate insights into device performance.

Some of the prominent remote monitoring examples are smart buildings, smart factories, eCommerce businesses, smart vehicles, and smart cities.

IoT enabled remote monitoring provides continuous, real-time visibility of data related to the equipment and the process. They empower operators and help them detect problems before they arise.