Industrial Internet of Things

- Home

- Industrial Internet of Things

Choose PsiBorg for Your IIoT Needs

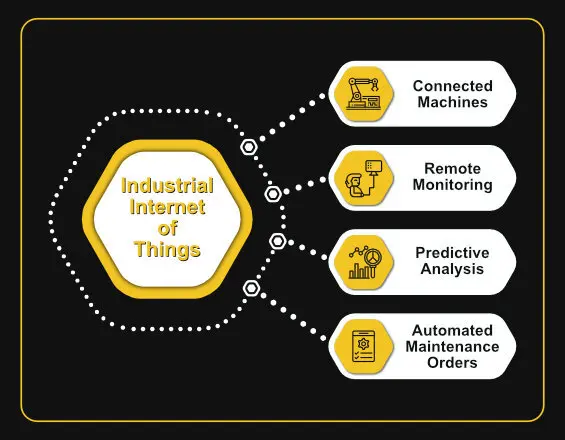

Industrial IoT solutions include connected devices and machines that can communicate with humans and assist them in monitoring and analyzing performance.

PsiBorg develops Industrial IoT systems to connect machines, people, and operations- to offer data-driven insights. With our Industrial IoT solutions like predictive maintenance and asset tracking, companies can visualize, analyze, and act on data to take a data-driven approach to increasing revenue. Start fast your digital transformation with PsiBorg’s IIoT solutions.

Introducing Industrial Internet of Things

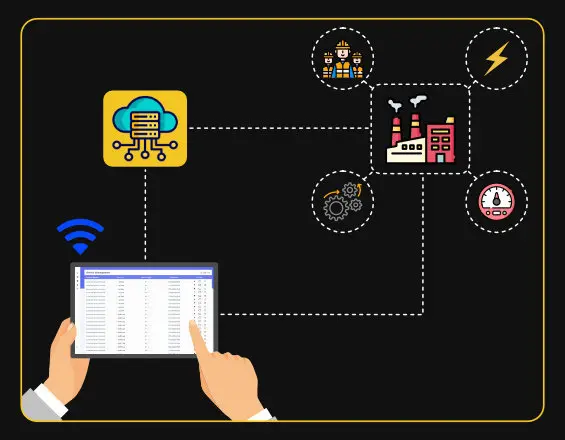

IoT is changing the way the companies operate from day to day thereby transforming the industries. When the big industrial data analysis is combined with machine to machine communication, great levels of efficiency, productivity and performance are achieved. Initially focusing on improving operational efficiency and automation, the Industrial Internet of Things has a great role to play in the manufacturing industry, asset performance management, industrial control thereby creating a demand service model, revenue model, better ways to serve customers and digital transformation.

Predictive Maintenance With IoT

Predictive maintenance is an integral part of IIoT, as there can be machineries that could be unsafe for the staff to work on. With IoT, any defects in those machines can be detected before they could harm any worker or stop working due to some small technical snag which could be resolved if known earlier. The potential of predicting the threat before and maintaining the machineries before something serious occurs is known as predictive maintenance.

IoT: Increasing The Brand Value

Today, companies that implement industrial remote Monitoring offer increased value to their customers and witness cost-effectiveness in operations. Also, an IIoT enabled unit where the parts of production lines are aware of each other’s activities in real-time become easier to control and run.

Benefits of IIoT

- The machinery used for business operational purposes can be monitored in real-time.

- If a machine gets damaged, then the whole process can get to hold. With the help of IIoT, the defects in machines can be detected before and can save the downtime.

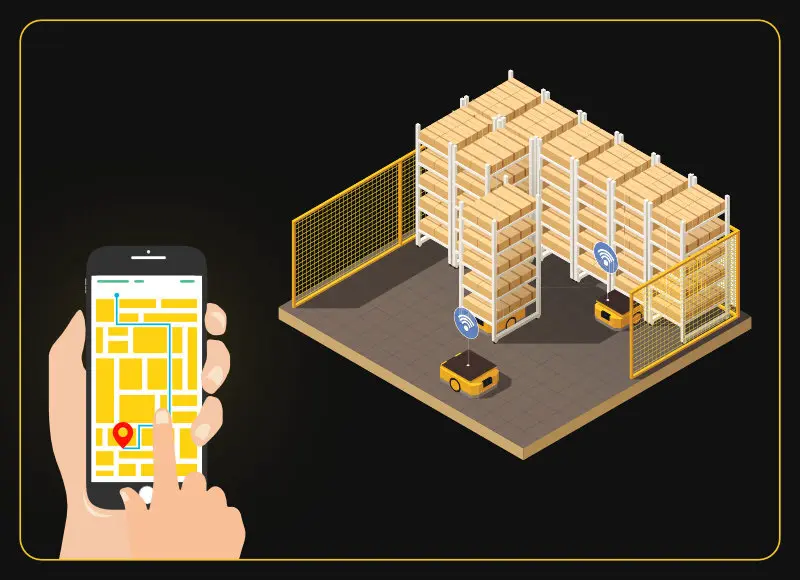

- IIoT allows the live tracking of the devices. This can tell the particular area of the defect without wasting time and thus reduce downtime.

- The machine analysis data can be fetched at any hour of the day due to real-time monitoring.

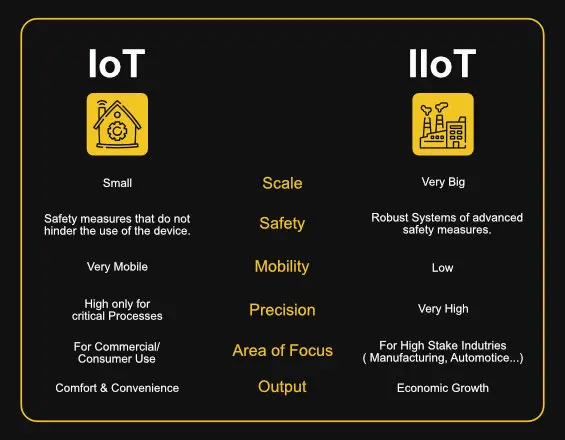

Difference Between IoT And IIoT

IoT and IIoT both deal with smart technology. Although both have differences as IoT is applied at the consumer level and IIoT is a more advanced level application of the Internet of things. Clearly, when the internet of things technology is used for small usage devices such as home appliances, Agriculture, security devices it is the fundamental IoT. When IoT is applied for the big machinery in big industries where industrial operations are dependent on these machines, then we say it as IIoT.

PsiBorg Technologies IIoT Services

If you are an industrialist and want to make a difference by peculiar operations, then undoubtedly you need the best machinery. We provide you with the power of unstoppable machinery so that you never face downtime and your processes continue smoothly. We are the best industrial IoT solution providers in India .We at PsiBorg will be giving you exposure to unexplored IIoT technology to help you grow in your industry. industrial IoT solution providers in India

Interested? Let’s Get Started

STEP 1

Contact Us

Reach out to us via the contact form or give us a call to initiate the conversation about your IoT development needs.

STEP 2

Get Consultation

Schedule a consultation with our experts to discuss your project in detail, aligning our approach with your unique vision.

STEP 3

Get a Cost Estimate

Receive a detailed cost estimate tailored to your project’s scope and requirements, ensuring transparency in your investment.

STEP 4

Project Kickoff

Once finalized, we'll initiate the project kickoff, marking the beginning of our collaborative journey toward successful IoT product development.

Why Choose PsiBorg?

Ready to elevate your IoT devices with advanced hardware design solutions? Contact us today to discuss your project requirements and explore the possibilities.

Industry-Leading IoT Expertise

With almost a decade of rich experience in IoT technology, we provide tailored services to various industries. Our team strives to deliver innovative and effective solutions that guarantee brilliant connectivity and automation.

End-to-End IoT Solutions – From Concept to Deployment

From the initial idea to launching your IoT project and providing continuous support, we take care of it all. You can completely focus on your business while we ensure a hassle-free experience for our clients.

Secure and Scalable Architecture

We guarantee you scalable, reliable and future-proof solutions. They are designed to provide operational efficiency, strong security, reduce downtime and align with your evolving needs.

Customized IoT Solutions for Diverse Industries

Trust us to offer tailored IoT applications that perfectly align with your specific industry requirements and deliver smart, efficient, and cost-effective solutions.

Our Process

1

Planning

PsiBorg starts any IoT development phase with planning. Firstly, the team experts strategically outline the scope and objectives of the solution and accordingly decide on resource allocation. The planning phase is the foundation of successful IoT solution development.

2

Analysis

After planning comes the requirement analysis stage, where the main objective is understanding the end user's needs and requirements. Our tech team gathers detailed insights to decide the flow of the development.

3

Design

In the design phase, a detailed blueprint of the project is created to clearly define the system’s architecture, data structure, and interfaces. In IoT solution development, the designing phase is also accompanied by prototyping, to validate the expected outcomes.

4

Implementation

In the implementation stage, the actual concept and product prototyping take place. The PsiBorg team, at this stage, initiates the MVP for the IoT solution. The implementation stage includes the development of all the hardware, firmware, and software. After implementation, the system undergoes integration and testing.

5

Testing & Integration

The testing stage is part of the development process because testing of the final product is necessary. Our team checks and thoroughly tests everything- hardware, firmware, and software. After conducting unit testing and validating the system, we deploy the project for production.

6

Maintenance

The final stage involves maintenance and support of the deployed solution. In the maintenance phase, PsiBorg offers to address waves, do updates, and provide ongoing assistance to the users.

Got problem worth solving or some amazing idea? Share with us!

Once you let us know your requirement, our technical expert will schedule a call and discuss your idea in detail post sign of an NDA.

All information will be kept confidential.

Speak with an expert

- Get help evaluating if PsiBorg is right partner for you

- Get information on IoT Solution and pricing

- Get a demo of how IoT can help with your use case

IoT Development Solutions for Every Industry

As one of the IoT product development companies, we deliver IoT products that are designed for performance, security, and longevity.

Automotive Industry: Manpower and Asset Tracking

For monitoring workforce productivity and efficiently managing valuable assets in the automotive sector, we build reliable IoT-based tracking solutions.

Mining Industry: Deployed Temperature and Humidity Monitoring

Our highly efficient IoT solutions help mining companies learn about the environmental conditions, ensure safety and comply with industry regulations.

Defence: Deployed Shipment Tracking Solution

To provide security and reliability in the defense sector, we provide real-time tracking solutions that help closely monitor the movement of all critical shipments.

Research and Development Sector: Cattle Health Monitoring System

Researchers and farmers can track cattle health, improve productivity and detect diseases early with our IoT-enabled livestock monitoring systems.

Consumer Electronics: SoS and Emergency Devices

Our IoT app development company provides efficient SoS and emergency devices that help in monitoring emergencies in real time and ensure quick responses and better safety.

Case Studies

The true success of a business lies in the trust and partnership cultivated between clients and the company. Click to read about some of our proudest achievements.

Frequently Asked Question

The Industrial Internet of Things (IIoT) is a term used for using the Internet of Things (IoT) in industrial sectors and focuses majorly on M2M communication, ML, and big data. The use of IIoT allows industries to improve efficiency and reliability in their business operations.

One example of the use of IIoT is fixing IoT sensors on factory machinery to monitor its status and allow the management team to perform predictive maintenance. In addition to this, some more examples of IIoT solutions are in-depth asset monitoring, high-quality product standards, safer working conditions, and faster response time.

The benefits of IIoT include automation, convenience, improved productivity, and efficient decision-making. Overall, IIoT enhances productivity, reduces downtime, and fosters innovation in industrial processes.

PsiBorg is an Industrial IoT solutions providing company that’s popular for developing innovative industrial-grade IoT solutions. PsiBorg is known for providing highly specialized end-to-end software-integrated IoT solutions that are of high quality and cost-efficient.

Industrial IIoT has vast use cases across a broad range of industries. In the manufacturing industry, by installing sensors on machines, the team can monitor their performance, thus improving efficiency, reducing waste, and increasing profitability. Moreover, some other industries that can avail benefits from adopting IIoT are healthcare, transportation, agriculture, and retail.

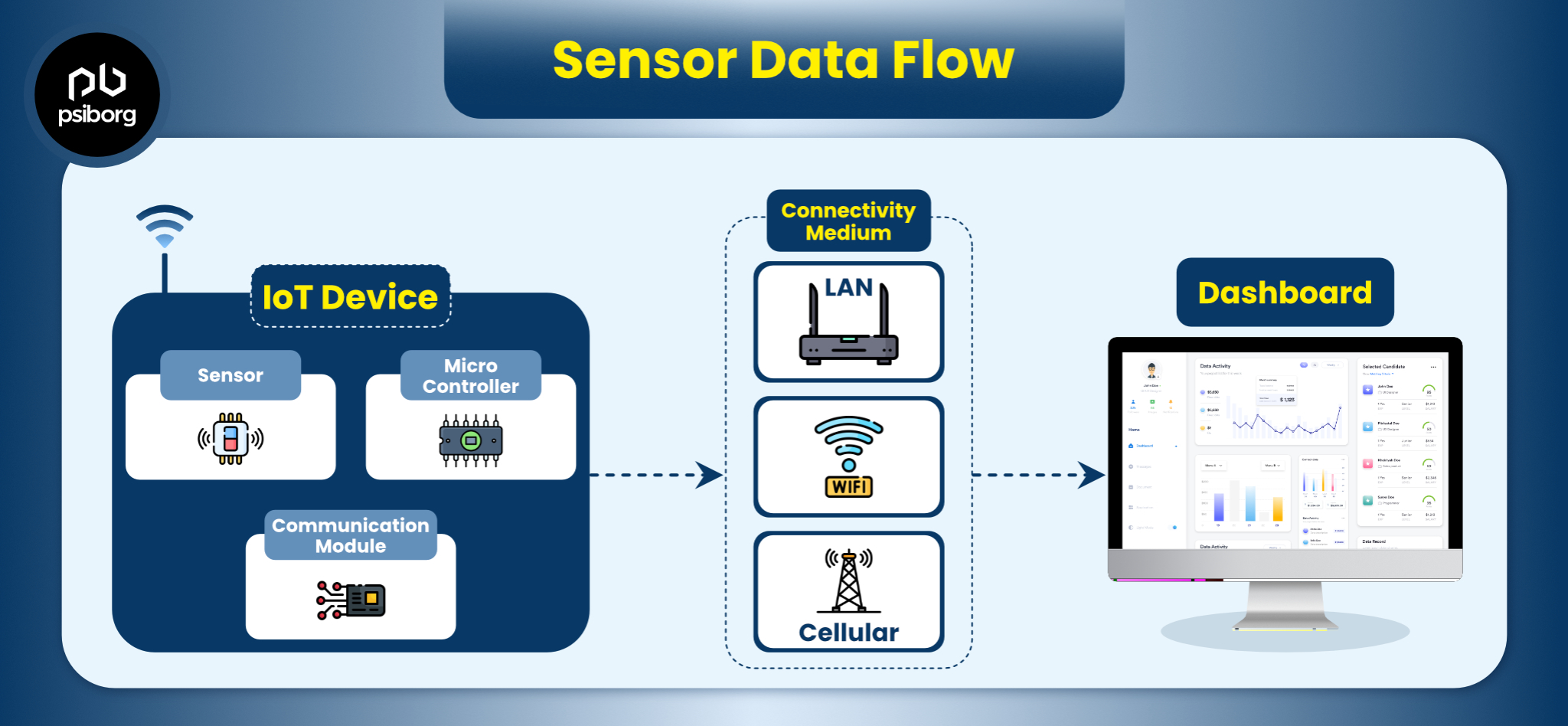

The major components of an IIoT system include sensors and actuators for data collection and control, connectivity infrastructure for data transmission, edge computing for local data processing, cloud platforms for centralized storage and analysis, and user interfaces for monitoring and control.