It’s so scary to think that the air you’re breathing is filling up with toxic gas and you have no idea about it because there’s no smell or no warning of any kind. Many industries face this invisible danger every day. Different toxic, flammable and odorless gases are constantly used across sectors and it’s impossible to catch them without technology.

Thankfully, a gas leak monitoring system guards the place and prevent small leaks from turning into deadly disasters. A reliable gas monitor ensures there’s no risk of massive financial losses and that lives are not on the line. Some industries absolutely need gas leak monitoring systems to keep their business and workers safe. Let’s find out which ones.

Why Gas Leak Monitoring is Critical for Industrial Safety

A workplace with invisible leaks is just like a ticking time bomb. There could be explosions, loss of lives and the whole facility could shut down. This makes a gas leak monitoring system a necessity in many industries. Various gases like methane, hydrogen sulfide, ammonia and even oxygen (in excessive concentration) are not safe. The scary part is that without a gas monitor, it’s not possible to detect them. Workers would keep working until it’s too late.

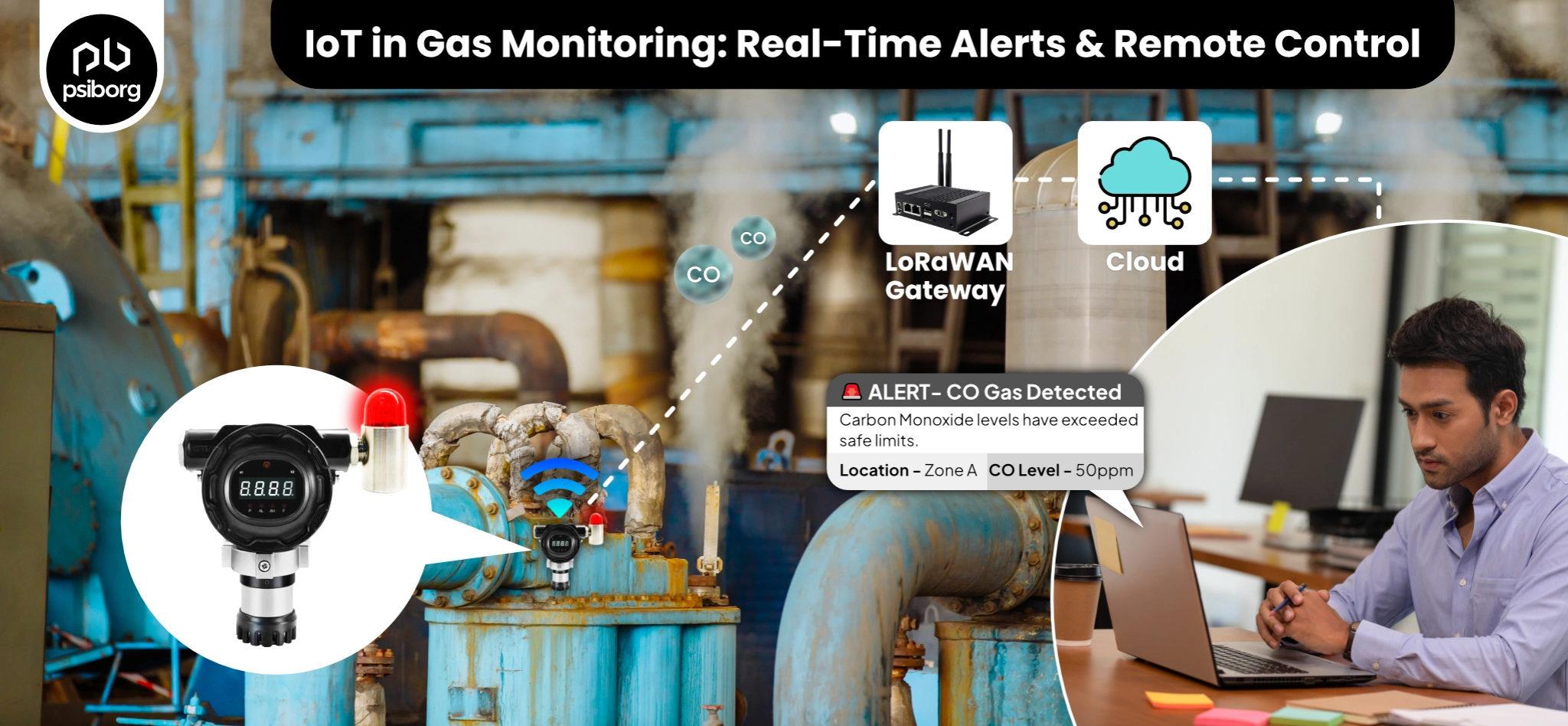

Gas leak detection systems take care of industrial safety by continuously scanning the environment, sending real-time alerts and preventing disasters. Having a gas leak detector can literally save so many lives across sectors, whether it’s a giant oil refinery, a pharma lab or a food storage facility.

5 Industries That Depend on Gas Leak Monitoring Systems

Here are the top 5 industries that can get the most affected by leakage of gases:

1. Oil & Gas Industry

This sector handles some of the most dangerous gases out there. Whether in the drilling of rigs or the storage tanks, it’s all so risky that a small leak can become a disastrous explosion in no time.

Preventing Explosions with Real-Time Gas Monitoring: A gas leak monitoring system ensures instant detection of dangerous gases like methane and hydrogen sulfide. Explosions, fires and worker exposure to toxic fumes can be prevented with real-time monitoring.

Gas Detection for Refineries and Pipelines: A gas leak detector is placed at critical points in refineries to monitor pressure levels, detect leaks and prevent mishaps. Pipelines that transport natural gas also hugely rely on industrial gas leak monitoring so that early leaks can be detected and losses can be minimized.

2. Mining Industry

One of the riskiest industries in the world is mining because there are a lot of hazardous gases underground. Sadly, miners have to work in such closed spaces where it air quality turns life-threatening very quickly.

Underground Gas Monitoring for Miner Safety: Carbon monoxide, hydrogen sulfide and other toxic gases are very common underground. Gas monitor gives real-time alerts to the miners as and when gas levels rise beyond safe limits and thus, saves countless lives every year.

Coal Mine Gas Detectors and Explosion Prevention: Buildup of methane in coal mines causes a serious danger because, without proper gas leak detection systems, methane can cause huge explosions. Coal mines swear by specialized gas leak detectors that can survive harsh underground conditions and give early warnings.

3. Chemical & Manufacturing Plants

Ammonia, chlorine or highly toxic industrial gases, chemical plants handle it all. Even if there’s a smallest leak, it can cause contamination, fire accidents or other life threatening situations.

Toxic Gas Monitoring in Industrial Environments: It’s possible to detect and track harmful gases with gas leak monitoring system before they could spread. This helps workers in chemical plants to stay safe while handling dangerous materials.

IoT-Enabled Gas Monitors for Worker Protection: The modern gas monitors are powered by IoT and can be connected to central systems. They help managers track real-time gas levels across different areas, get instant alerts and evacuate workers from the place if necessary. A gas leak detector is as essential as fire alarms for manufacturing plants that deal with plastics, paints or maybe fertilizers.

4. Healthcare & Pharmaceuticals

Dangerous gases won’t even cross our mind when thinking of hospitals. Most of us don’t realize that healthcare facilities and pharmaceutical plants deal with medical gases like oxygen, nitrous oxide or toxic lab chemicals.

Medical Gas Monitoring for Patient & Staff Safety: Oxygen leaks can cause fires in hospitals and leaking of nitrous oxide can harm staff. A gas leak monitoring system is required to ensure that these medical gases stay under control because it’s the matter of patient safety.

Role of Gas Leak Detection in Laboratories: Gases are used in pharmaceutical labs for research and production. If a gas leak detector is placed in the labs, it will prevent contamination, protect researchers and avoid destructive accidents. Hence, both people and life-saving medical research will be saved.

5. Food & Beverage Industry

The food industry is also dangerous in the sense that many food and beverage companies rely a lot on gases for the storage and processing of items.

Ammonia and CO₂ Monitoring in Cold Storages: It’s a common practice to use ammonia-based refrigeration in cold storage warehouses. While they are very useful, ammonia leaks are also extremely dangerous and lead to extreme health issues. However, it’s possible to ensures safe storage of food products with a gas leak detection system. No risk to worker health. Carbon dioxide (CO₂) is also used for chilling and carbonation. Without gas leak monitoring, high levels of it can be poisonous in enclosed spaces.

Gas Detection in Breweries and Food Processing: Breweries use CO₂ during fermentation and without gas monitors, staff could be exposed to high gas concentrations and they won’t even know it. Gas leak detectors food processing plants ensure a safe production line.

Benefits of Gas Leak Monitoring Systems Across Industries

It’s clear how gas detection is so important across different industries. But what is it that makes these systems so powerful? Let’s discuss the biggest benefits it offers:

Real-Time Alerts & IoT Integration

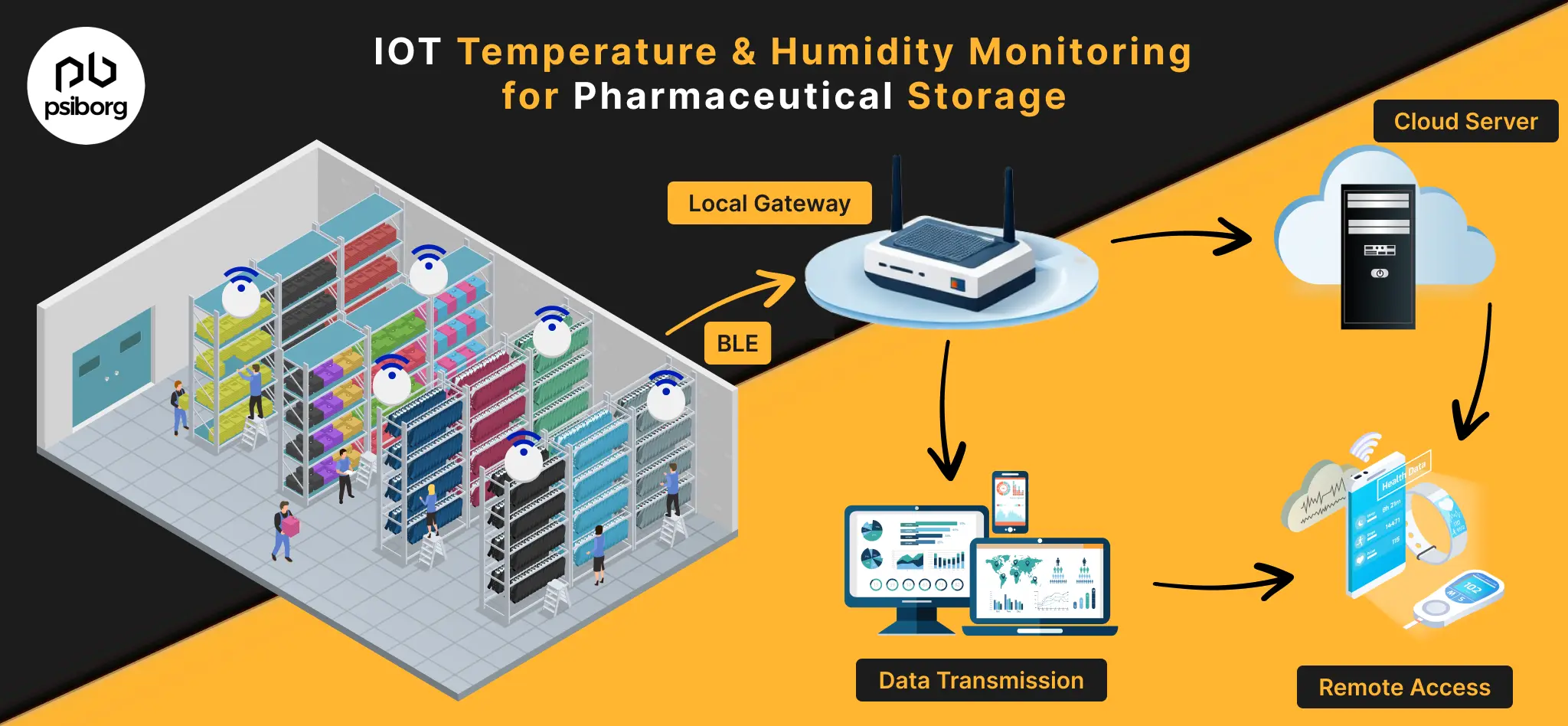

The new age industrial gas leak monitoring systems use smart technology. Besides detecting leaks being the basic feature, they also send real-time alerts to smartphones, control rooms and safety systems. The IoT integration in the system helps managers monitor safety even remotely.

Compliance with Safety Regulations

Every major industry has to strictly follow the underlying safety regulations. A gas leak detection system in place ensures that the companies are meeting the required standards and avoiding fines, shutdowns or legal actions.

Preventing Financial & Human Losses

Practically speaking, the cost of installing a gas leak detector is nothing when compared to the loss a company faces after an explosion, fire or other toxic mishap. Putting these systems in place will actually save a lot of money and workers’ lives and help follow industrial safety practices.

Suggested Reading: IoT in Oil and gas industry

Conclusion

A gas leak monitoring system is a life-saving shield that makes workplaces safer, cleaner and more efficient. We learned that the discussed five industries we explored simply cannot function without reliable gas leak detection systems.

Gas monitoring is non-negotiable in a world where even a tiny invisible leak can cause massive destruction. At Psiborg, we specialize in designing and implementing smart industrial gas leak monitoring solutions that don’t just detect leaks but prevent disasters. Our systems are built to protect people, processes, as well as profits. Trust our services and operate with confidence and safety!

FAQs

The leaking of methane, hydrogen sulfide or other flammable gases in the oil & gas sector can ve really fatal. They can quickly cause fires, explosions or exposure to harmful air. A gas leak monitoring system helps by providing real-time alerts. It prevents accidents, protects workers and also reduces downtime costs.

Often there are methane, carbon monoxide and other dangerous gases in the mining sites. This makes worker safety a matter of extreme concern. A gas monitor will ensure that the underground air quality is safe and will warn miners before gas levels reach hazardous limits. That’s how these monitors prevent explosions and save lives.

It’s common for hospitals and labs make use of oxygen, nitrous oxide, carbon dioxide and other gases. Here, the role of gas leak detectors is to make sure that these gases are used very carefully so that there are no such leaks that can harm patients, staff or ongoing medical research.

These facilities carefully watch out for the presence of ammonia, chlorine, hydrogen sulfide and flammable organic mixes. Only through a gas leak detection system can a safe working environment be ensured; without leaks or accidents.

IoT-enabled industrial gas leak monitoring systems are designed to connect detectors to central networks. That’s how they help in real-time tracking, quick alerts and remote monitoring. It’s a smart integration that improves response times and improves safety management.

For measuring gas concentrations in the air, a gas leak detector makes the use of advanced sensors. If it sees that the levels are exceeding safe limits, it instantly triggers alarms so that a required action can be taken before any disaster occurs.