Heavy equipment especially construction equipment is essential to a variety of industries, including mining, construction, and manufacturing.

These equipments are necessary for large scale activities where heavy workloads are involved. Thus, it is essential for business success to ensure that they are performing at their best.

Effective maintenance not only increases production, efficient maintenance also reduces downtime. In this blog, we’ll look at the best practices for machine maintenance, how to extend the life of heavy machinery, and what maintenance involves.

What is Heavy Equipment Maintenance?

Heavy equipment maintenance is designed to assist industries in monitoring, controlling, and improving the maintenance of their equipment. Fleet management and maintenance teams can use this software to schedule and plan regular inspections by tracking repair history, planning and scheduling routine inspections.

Additionally, these solutions can integrate with equipment tracking to track where equipment is, how much it’s being used, and its movement. It also tracks who is using the equipment, when it’s idle and how many hours it’s been in use, which helps optimize equipment.

Features of Heavy Equipment Maintenance System

PsiBorg’s Heavy Equipment Maintenance systsem offered various features which help to extend equipment lifespan and maintain the best possible condition for your equipment:

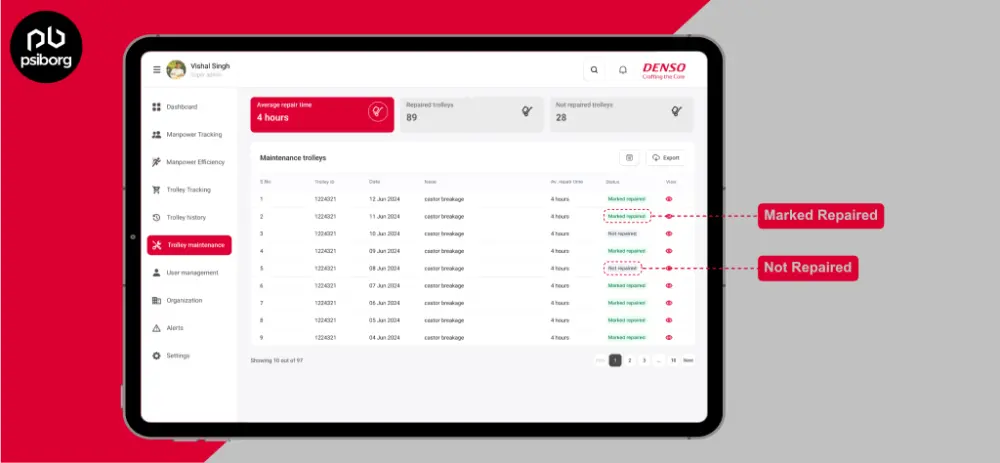

1. Equipment Maintenance

It involves regular inspections, repairs, and part replacements to ensure machinery operates efficiently, reducing downtime and extending its lifespan. Key features include the Mark Repaired status to track repaired equipment. The mark Not Repaired status identifies equipment that has not been repaired yet or is in a pending repair state, which helps optimize repair costs, resource allocation, and informed decisions on replacements.

2. Equipment Efficiency Monitoring

It monitors equipment health, operational performance and idle time to identify cost-saving opportunities. It tracks equipment utilization rates to ensure optimal use and analyzes the impact of maintenance on performance.

These factors will help to improve productivity, reduce cost, and enhance overall machine efficiency.

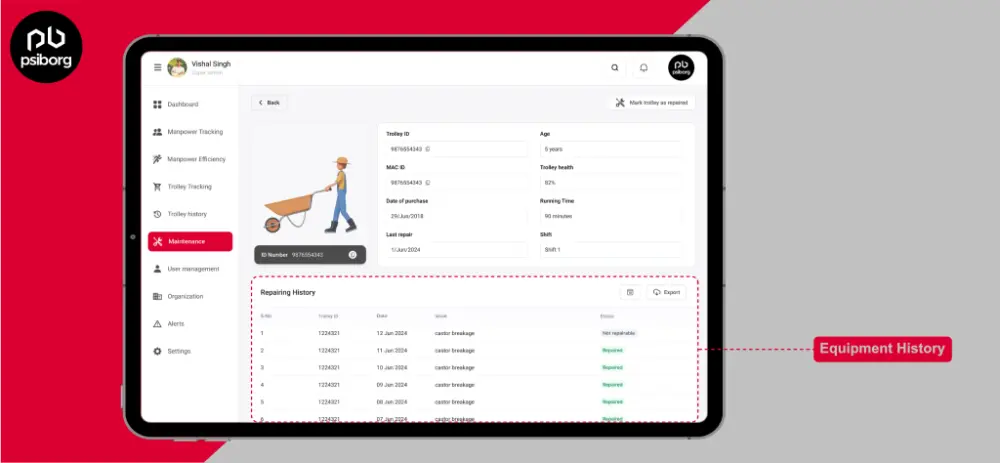

3. Equipment History Analysis

Equipment History provides a complete record of a machine’s life. It includes service history that tracks routine maintenance such as last servicing, inspections, oil changes, and part replacements. Repair History documents major repairs, including the issues fixed, parts replaced, and associated costs. Usage History records how often the equipment is used, its operating hours, and the work environment. Incident History notes any accidents or safety issues, while Modification History tracks upgrades or changes made to the equipment. Finally, Compliance History ensures the equipment meets regulatory standards with safety inspections and certifications.

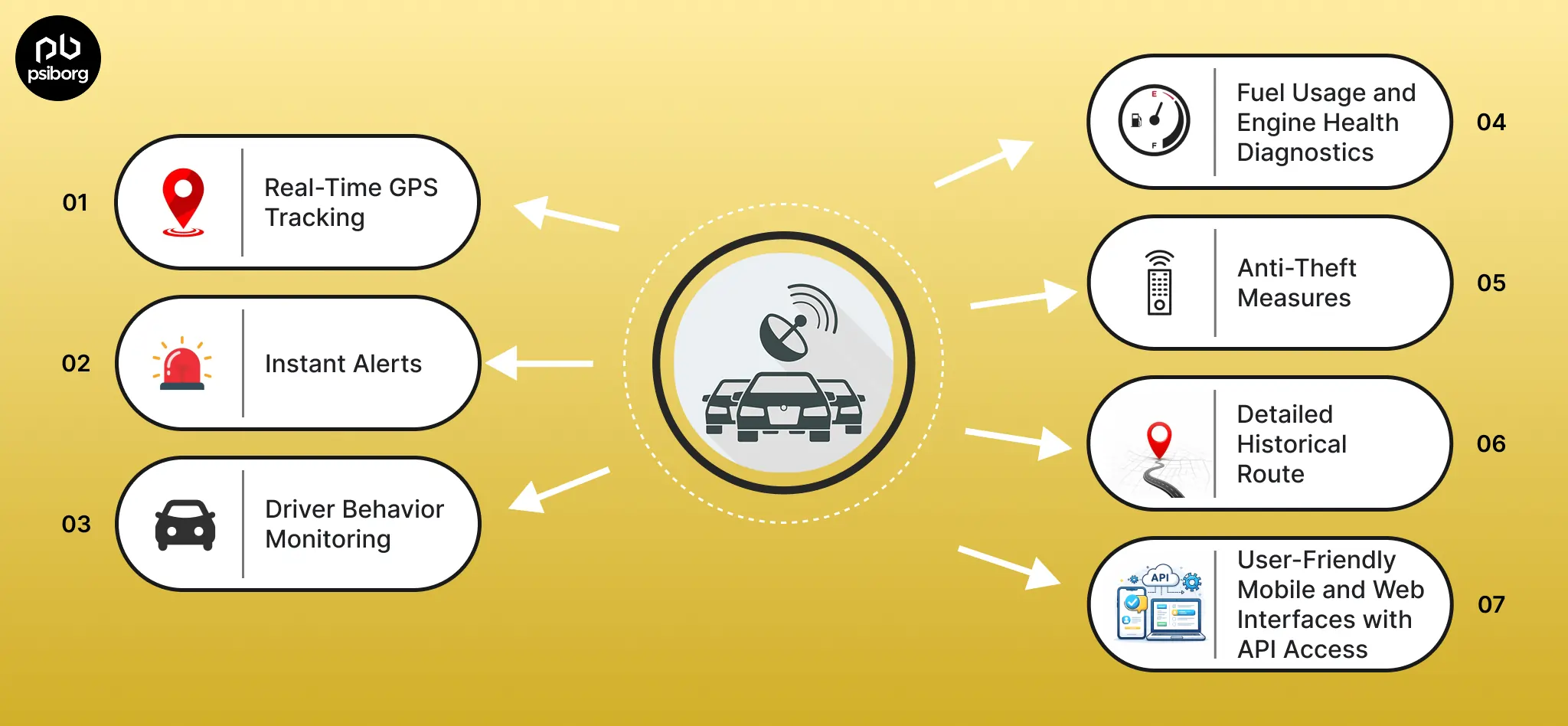

4. Equipment Tracking

With BLE technology, equipment tracking helps to monitor where equipment is, how much it’s being used, and its movement.

It also tracks who is using the equipment, when it’s idle, and how many hours it’s been in use. This helps optimize equipment use and schedule maintenance when needed.

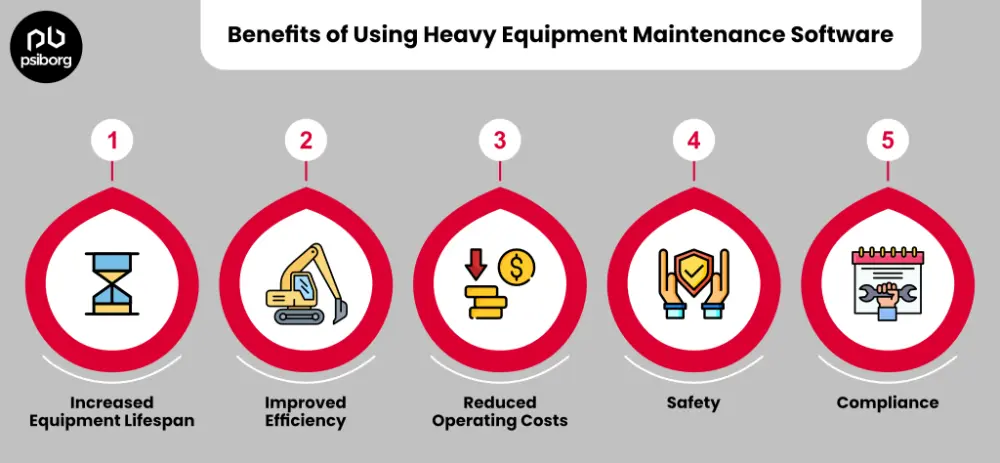

Benefits of Using Heavy Equipment Maintenance Software

Proper maintenance of heavy equipment offers various benefits:

Increased Equipment Lifespan

Regular maintenance extends the lifespan of machinery by preventing premature wear and tear.

Improved Efficiency

Well-maintained construction equipment operates more smoothly and efficiently, which leads to better performance and productivity.

Reduced Operating Costs

By preventing major breakdowns, you save on costly repairs, replacement parts, and downtime.

Safety of Workers

Making sure that equipment is maintained correctly which reduces the possibility of injuries and accidents.

Compliance

Regular maintenance ensures that equipment remains compliant with regulatory standards and safety requirements.

Heavy Equipment Maintenance Checklist: How to Maintain Heavy Equipment

Effective maintenance is best achieved by following a structured approach. Here’s a checklist to guide you:

1. Inspecting the Machine from Ground Level

Make sure the tires or tracks are well-inflated and clear of cuts, punctures, or abrasions before starting to check for wear indicators.

Any tires or tracks with noticeable damage should be replaced. Next, check for any leaks, splits, or bulging in the hydraulic hoses since these could be signs of failure.

Make that all of the lights and warning signs are working as well. At last, to guarantee optimum performance and avoid damage, periodically check the levels of all fluids, including hydraulic, coolant, and oil.

2. Machine-Specific Inspection

Every piece of heavy machinery has certain maintenance needs. Always consult the manufacturer’s instructions for specialized inspections, like checking the boom, bucket, or any particular attachments.

Verifying that all safety features and controls are operating as planned is also crucial for ensuring the equipment runs effectively and safely.

3. Inspecting the Engine Compartment

One important place for maintenance is the engine compartment. Check and replace air filters as necessary because clogged filters can restrict airflow and lower engine efficiency.

Make sure the belts and pulleys are correctly tensioned and inspect them for wear or cracks. Keep an eye out for any indications of fluid leaks that can cause the engine to overheat or lose lubrication, as these conditions could seriously harm it.

4. Inspecting the Cab

To avoid stress while operating, make sure the operator’s seat is comfortable and correctly set. To ensure smooth functioning, verify each button, lever, and pedal in the control systems.

Also, for safe operation and accident prevention, make sure that all mirrors, windows, and cameras are clean and offer good visibility.

What Approach to Heavy Equipment Maintenance Works Best?

A combination of predictive maintenance, corrective maintenance, and preventive maintenance is the most efficient method for maintaining heavy machinery. Let’s take an overview of these approaches are defined below:

Preventive maintenance

It aims to stop failures before they happen by implementing planned procedures such as lubrication, inspections, and part replacements. It is the foundation of every maintenance strategy since it keeps equipment operating efficiently and reduces the chance of unplanned breakdowns.

Predictive Maintenance

It uses real-time equipment monitoring through the application of technology like vibration analysis and Internet of Things sensors. Predictive maintenance uses data analysis to identify possible problems before they occur, reducing downtime, increasing equipment lifespan, and enabling just-in-time maintenance.

Corrective Maintenance

This is performed after a failure has occurred. It involves repairing or replacing damaged components, but it can be expensive due to longer downtimes and higher repair costs, making it less efficient than preventive maintenance or predictive Maintenance.

Emerging Technologies in Equipment Maintenance

With technological advancements, heavy equipment maintenance is becoming more efficient and data-driven. Some of the most notable innovations include:

IoT Sensors

These wireless sensors can continuously monitor construction equipment and notify operators of possible problems such as low fluid levels or overheating.

Condition-Based Monitoring

Using IoT, you can monitor equipment conditions through vibration, temperature, and oil pressure sensors to predict failures before they happen.

AI and Machine Learning

AI systems analyze maintenance data to optimize schedules and predict when a component will fail, helping to reduce unexpected breakdowns.

Drones for Inspections

Drones with cameras and sensors can examine massive equipment in difficult-to-reach places by producing thorough reports and avoiding human error.

Conclusion

Overall, heavy equipment maintenance is important for enhancing durability, improving productivity and minimizing costly repairs. By integrating preventive, predictive, and corrective maintenance strategies with heavy equipment maintenance software businesses can ensure their machinery operates efficiently.

The use of advanced technologies like IoT sensors, AI and drones further optimizes maintenance processes through real-time monitoring and data-driven insights. A comprehensive maintenance approach is good for effective fleet management, as it ultimately boosts productivity, enhances safety and ensures compliance.

FAQs

Regular maintenance is essential to ensure that heavy equipment runs efficiently, minimizing the risk of unexpected breakdowns. Routine inspections can extend the lifespan of machinery, prevent costly repairs, and improve safety on the job site. Additionally, using heavy equipment maintenance software and mobile apps can streamline scheduling, record-keeping, and timely maintenance checks.

Heavy equipment preventive maintenance involves scheduled tasks like inspections, lubrication, and part replacements to prevent failures. By integrating a heavy equipment maintenance app, businesses can streamline PM tasks, ensuring equipment remains in optimal condition and reducing downtime.

To reduce costs in heavy equipment management, implement heavy equipment preventive maintenance, use heavy equipment maintenance software for tracking repairs, and monitor equipment performance. Additionally, utilizing an app for efficient scheduling and operator training helps avoid unnecessary repairs and downtime.