The mining industry holds a really high value. Besides powering electricity and supplying raw materials to different sectors, it employs numerous workers and practically supports economies around the world. However, it’s also one of the riskiest jobs. Miners spend hours and hours working in enclosed tunnels where danger enters in the form of highly toxic gases. Sadly, many of the world’s most tragic mining disasters have been caused by undetected gas leaks and explosions. Thankfully, this can now be controlled with underground gas monitoring.

Real-time underground gas monitoring is sure a lifesaver. Smart sensors, mining gas detectors and IoT in the mining industry help companies detect harmful gases, instantly alert workers, and prevent scary accidents. Here, we’ll understand the concept of underground gas monitoring, why the detection of mine gases is important, and all the details around this topic.

What is underground gas monitoring in mining?

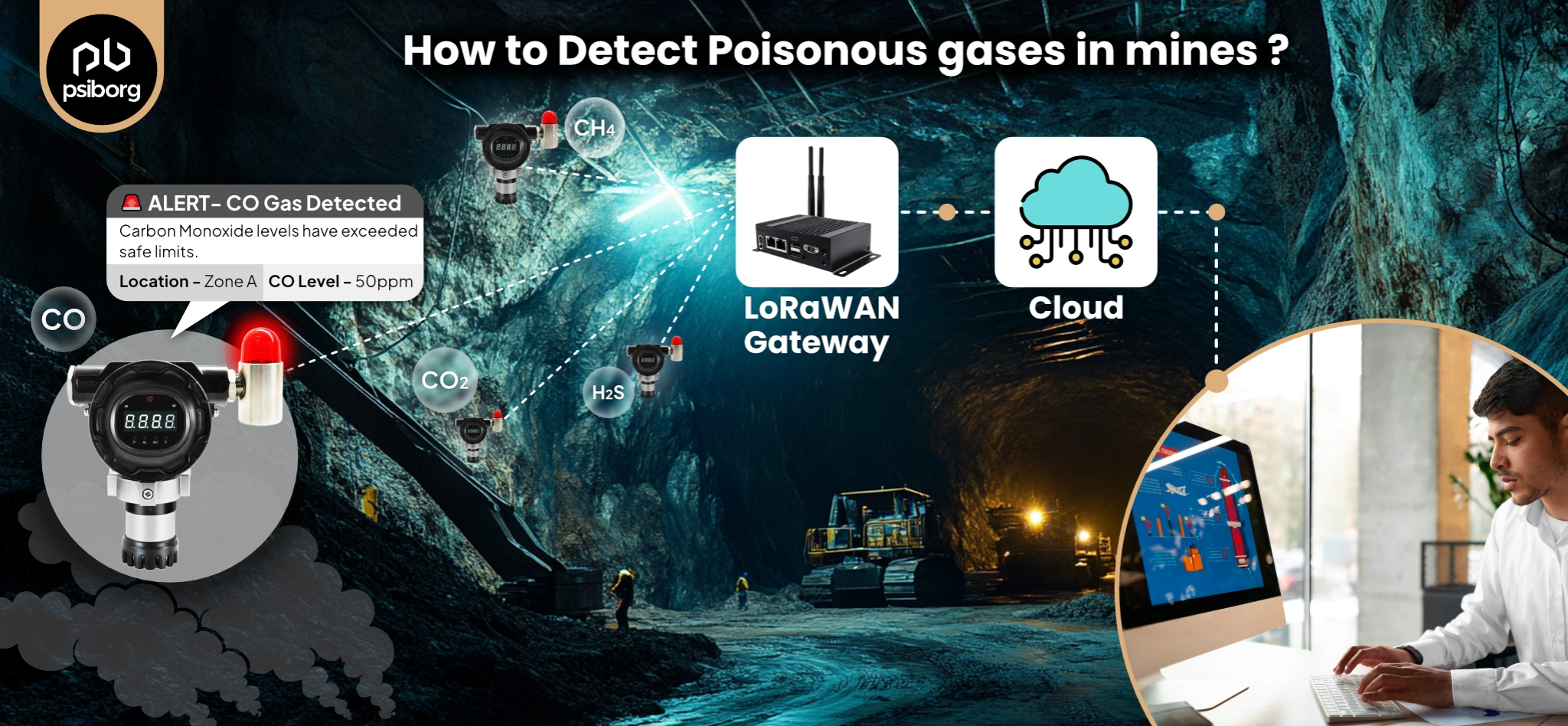

Underground mining environments are prone to the accumulation of hazardous gases such as methane (CH₄), carbon monoxide (CO), and hydrogen sulfide (H₂S), which pose serious risks to workers’ health and safety. Effective gas detection systems are crucial to detect unsafe conditions in real time and prevent accidents. Underground gas monitoring systems continuously detects and analyzes the presence of these gases through mining gas monitoring systems and mining gas detection equipment in real time.

The purpose of underground gas monitoring

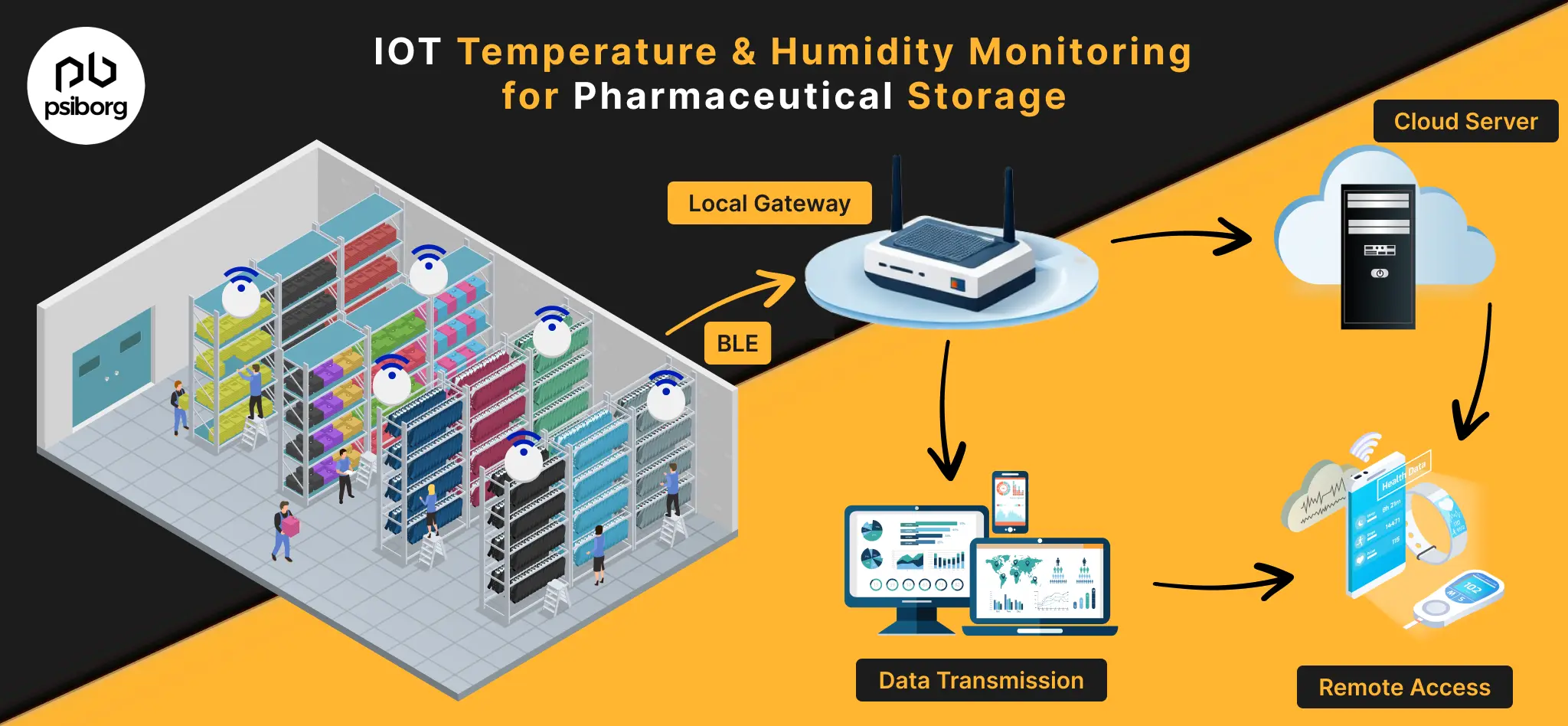

The setup is done in a way that mining gas detectors are connected to control systems above the ground, which makes it easy for the supervisors to see gas readings from different areas at once. Even IoT-enabled mining gas monitoring solutions are used in some mines. Basically, detectors are connected to cloud-based dashboards that can be remotely accessed.

- Detecting danger before it builds: The presence of toxins, deficiency of oxygen or explosive gases in the air.

- Providing real-time alerts: Both miners and managers are immediately informed to leave the place or take preventive action.

- Compliance with safety standards: It helps adhere to government-set regulations for mining companies.

- Preventing disasters: Unfortunate situations like fires, suffocation and other incidents can really be controlled.

To monitor Lone workers, you can also check our Lone Worker Safety Devices.

Underground gas monitoring: how to detect poisonous gases in mines

Mining is a task that needs to disturb the natural layers of the rock. There are gases that have been trapped for millions of years. Now, drilling, blasting, or coal extraction releases those gases, and they can be collected in tunnels very quickly.

Now the question is, how do mines detect these gases before they could harm workers?

Modern technology in gas detection in mining industry can detect poisonous gases in mines that no human senses can.

1. Mining Gas Detectors

There are majorly two categories of mining gas detectors

Portable Gas Detectors – Carried by Workers

These are compact, lightweight devices designed to be worn by miners throughout their shifts.

Purpose:

Provides continuous real-time monitoring of the worker’s immediate environment.

Key Benefits:

- Instant alerts to the worker when dangerous gas concentrations are detected.

- Personal safety in dynamic underground conditions.

- Often equipped with SOS button, fall detection, and logging for compliance.Use Case:

A miner navigating through the coal face carries a portable gas detector, receiving immediate warnings if methane levels rise beyond safe limits.

Fixed Gas Detectors – Mounted in Mine Infrastructure

These gas detectors are installed at strategic locations in the mine, such as shafts, tunnels, or ventilation areas.

Purpose:

Provides area-wide, continuous monitoring of gas concentrations.

Key Benefits:

- Detect gas build-ups in key locations over time.

- Centralized data helps in long-term analysis of hazardous areas.

2. Real-Time Alerts and IoT Integration

IoT in the mining industry has made gas detectors smarter than ever. It’s more than measuring gas levels. Data is shared to a central dashboard, alerts are sent to Admin mobiles, and even automated safety systems are triggered so that everyone is safe at all times.

3. Coal Mine Gas Monitoring and Alerts

In many countries, continuous coal mine gas monitoring is mandatory so explosions can be prevented. Thankfully, advanced detectors work 24/7 surveillance so that even the smallest gas leaks are noticed and reported.

What are the different types of gases found in underground mines?

The detection of mine gases is a very thoughtful idea. Not only does it prevent explosions, it also to ensure miners don’t keep breathing toxic air when they’re working underground. While not all of these gases are equally dangerous, many underground gases can be deadly, especially if not paid attention to. Here we have the most common ones:

1. Methane (CH₄)

Methane is a natural byproduct that is released from the layers of coal. It’s highly flammable and can cause massive explosions if mixed with air in a certain amount. The reason coal mine gas detectors are placed is that they efficiently track methane.

2. Carbon Monoxide (CO)

When coal or engines underground don’t burn completely, they create this gas. It has no color or odor but is extremely toxic even when inhaled in small amounts. The ill-effect of breathing in carbon monoxide can range from headaches to blackout and even death.

3. Hydrogen Sulfide (H₂S)

It initially smells like a rotten egg smell but if it’s inhaled a lot, it paralyzes the sense of smell and you are not able to detect it any further. Being highly poisonous, it can make workers drop on the group and even lose their lives.

4. Carbon Dioxide (CO₂)

Old or poorly ventilated mines are more likely to have it there. CO₂ gets collected in low-lying areas and reduces the level of oxygen there making it hard to breathe. This harmful gas being in the air makes workers suffocated and lose their consciousness.

5. Nitrogen Dioxide (NO₂)

It is usually released from diesel machinery that is used underground and can irritate the lungs and even cause long-term damage to the respiratory system.

6. Oxygen Deficiency

Oxygen levels can also drop below safe limits in different sections of the mine. Because of lack of ventilation different ther gases replace oxygen and creates a very harmful situation. Workers in those particular areas can quickly lose consciousness in no time.

The role of IoT in mining industry safety

Technology has improved mining safety a lot, especially with the entry of IoT in mining industry. With smart mining gas monitoring, accidents can actually be prevented. Let’s see how IoT is making monitoring of gas smarter and safer than ever:

Real-Time Tracking:

IoT-enabled mining gas detectors keep sending live data to cloud systems. Supervisors can easily check gas levels from their mobile or control room.

Predictive Analytics:

A pattern is predicted from the data collected from detectors. For example, which tunnels have higher methane levels? This way, preventive action can be taken.

Automated Responses:

In case dangerous gases are detected, the smart systems automatically switch on ventilation fans or shut down machines .

Worker Safety Wearables:

Some gas detection systems are also wearable and provide an added layer of protection.

Why real-time underground gas monitoring is essential?

Even today, there are incidents of mining disasters caused by gas explosions or toxic buildup. It happens in places where safety systems are either outdated or ignored. The reasons why gas detection in mining industry operations has become a gold standard are:

- By giving miners early warnings, it protects the lives of the workers.

- It prevents financial losses that are followed by the closure of mines, legal actions and equipment damage during an accident.

- Companies don’t skip complying with safety laws and environmental regulations.

- A level of trust is built between companies and workers because it reflects that safety is the priority.

If you look at the larger picture, the cost of installing mining gas detection equipment is like nothing against the loss due to a single accident.

Conclusion

There will always be risks in mining, but the right technology helps in managing them effectively. With underground gas monitoring systems in place, deadly gases are no longer a threat to lives. Mining gas detectors, coal mine gas monitoring, and IoT in mining industry make mining a lot safer. Real-time gas detection in the mining industry is necessary. At PsiBorg, we help deploy smart gas monitoring systems for sustainable and more efficient underground operations. Get in touch with the best monitoring solutions!

FAQs

It’s the process of continuous tracking of harmful gases inside tunnels like methane, carbon monoxide etc. Specialized mining gas detectors and sensors are used to ensure miners breathe in safe air and there is no explosion or risk of suffocation.

IoT connects sensors to a central system that shows real-time gas levels throughout the mine. Instant alerts are sent to miners and supervisors if any danger is detected. It also triggers automatic safety actions like turning on ventilation fans. Smart detection, faster action!

Mining gas detectors and coal mine gas monitoring equipment are used to detect poisonous gases. These devices keep on measuring gas levels, alert when the safe limits are crossed and send real-time data to control rooms to take quick action.

Sure! And once IoT-based mining gas detection equipment is integrated with safety dashboards or your ERP system, supervisors can see live gas readings from different sections of the mine, identify patterns, and take preventive measures instantly.

This technology gives accurate data, ensures instant alerts, helps with predictive analysis, and provides automated safety responses. The presence of IoT in the mining industry for gas detection prevents accidents, improves worker safety and enhances mining efficiency.

PsiBorg brings to you the best-in-class IoT-powered gas detection in mining industry for real-time monitoring, cloud-based dashboards, and auto safety triggers. With smart sensors and connectivity, our solutions ensure safer and more reliable operations.