Real-time location systems for Worker Tracking Solution are central to modern safety programmes, 83% of employees say they are open to using new safety technologies, underlining readiness for adoption.

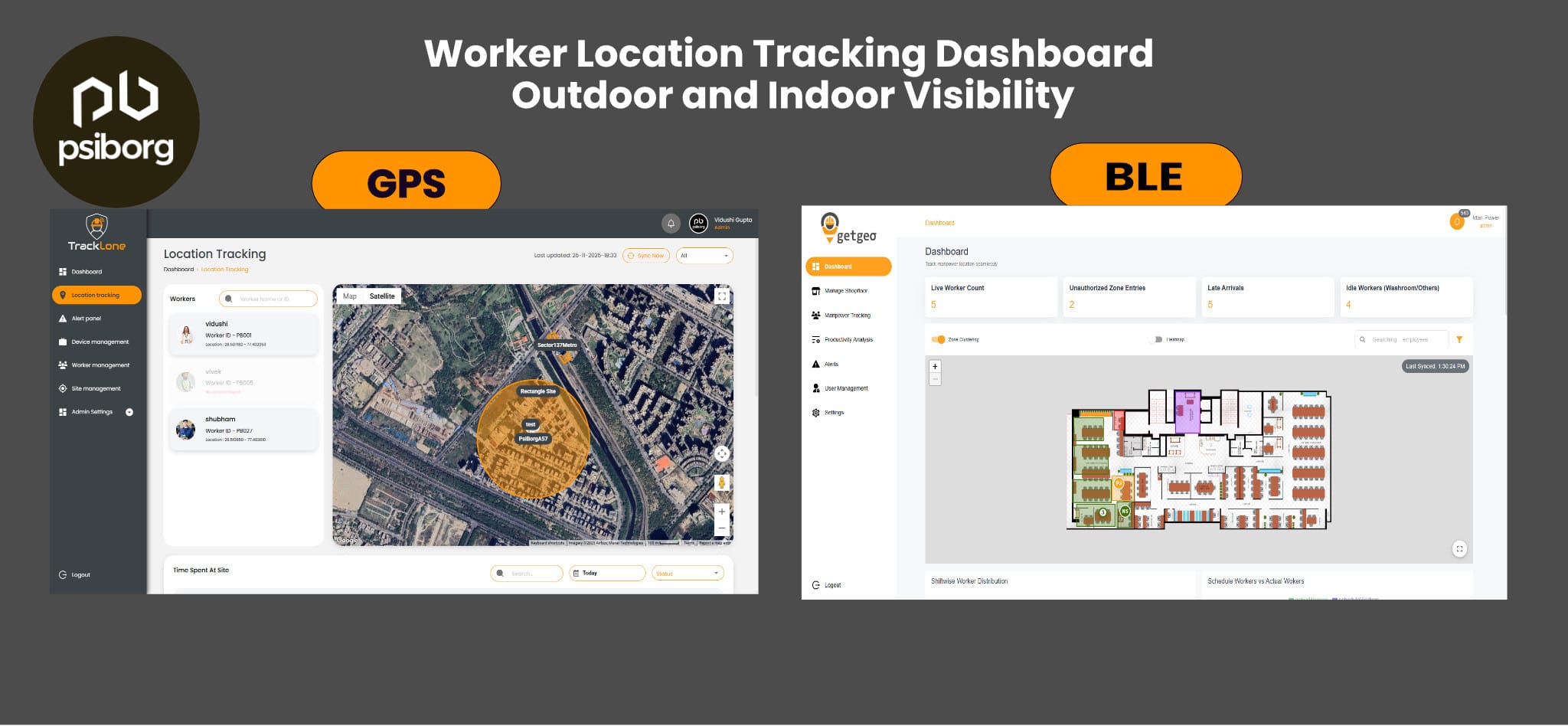

BLE beacons excel indoors for room-level visibility while GPS remains the reliable choice outdoors, knowing this split avoids costly blind spots.

So making the right BLE vs GPS choice matters for safety, compliance and ROI; this blog explains when to use each, hybrid approaches and procurement tips.

Broadly Speaking , If you want to track worker movement on factory Layout , BLE is suitable. And if you want to track a worker on GPS map , Cellular device with GPS is suitable.

Read on to optimize your workforce management and boost operational control with data-driven decisions.

What Is a Worker Tracking Solution?

A worker tracking solution is an integrated system of devices, sensors, and software that provides real-time or near–real-time insight into where workers are, what risks they face, and how they move across indoor and outdoor environments.

It acts as a safety and operations intelligence layer over your physical workplace, helping you prevent incidents, accelerate emergency response, and streamline operations.

A worker tracking device actually tracks:

Location Visibility

- Zone, room, floor, and building-level visibility

- Indoor/outdoor transitions

- Entry and exit events for controlled or restricted areas

Movement Patterns

- Routes taken across a shift

- Dwell time in hazardous or sensitive zones

- Repetitive patterns (useful for bottleneck analysis)

Risk & Safety Signals

- Man-down or no-movement detection

- SOS/duress button events

- Hazard proximity alerts (e.g., heavy equipment, exclusion zones)

Operational Indicators

- Real-time mustering status

- Workforce distribution across lines or buildings

- Understaffed or congested areas

You now know what a worker tracking system is, so the next step is understanding why businesses actually need one and what real problems it solves.

Why Do Businesses Need Worker Tracking Systems?

A modern worker tracking system isn’t a convenience, it’s a risk, efficiency, and accountability engine that directly impacts safety, operations, compliance, and profitability.

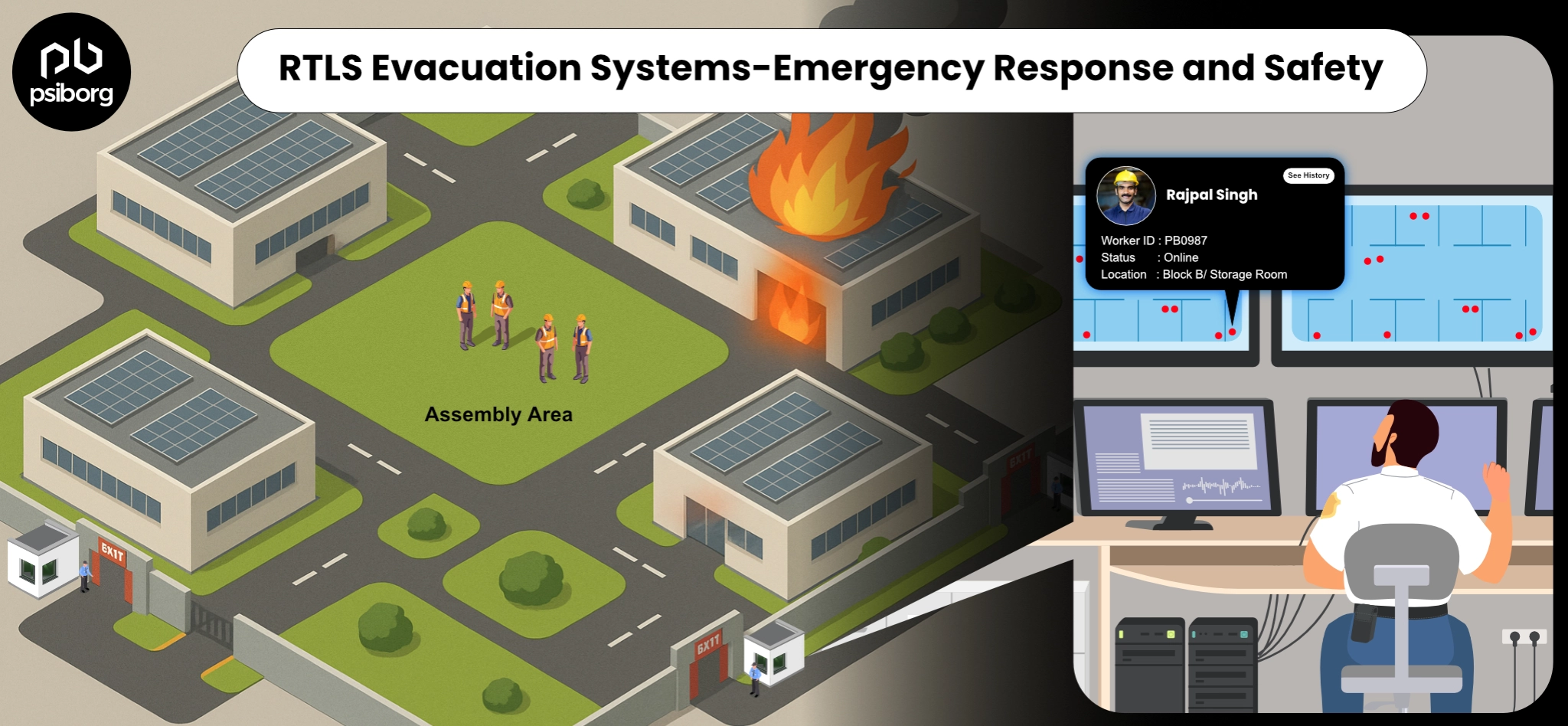

1. Reduce Incident Severity & Speed Up Emergency Response

Worker tracking provides real-time visibility during the moments that matter most. It enables:

- Know exactly who is still inside the facility during an evacuation.

- Identify workers in blast zones, fall-hazard areas, or chemical rooms.

- Detect man-down/no-movement events and respond instantly.

- Trigger SOS alerts tied to precise indoor or outdoor location.

2. Strengthen Compliance & Simplify Audits

Regulators and insurers demand proof of control, not assumptions. With a tracking system, you can:

- Automatically log who entered controlled or permit-required spaces.

- Prove only certified workers accessed hazardous zones.

- Export 30–90 days of location history for audits or insurance reviews.

- Reconstruct movement paths for root-cause analysis.

3. Improve Operational Efficiency & Workforce Allocation

Visibility removes guesswork from daily operations. You gain the ability to:

- See which zones are under- or over-staffed in real time.

- Reassign workers without waiting for radio confirmations.

- Reduce idle time caused by waiting for supervisors, drivers, or inspectors.

- Balance workflows across large plants, multi-building campuses, or yards.

4. Protect Lone & Remote Workers

For field Worker safety monitoring and night-shift personnel, visibility is crucial. Tracking systems allow you to:

- Track lone workers’ last-known position.

- Trigger alerts when movement stops in high-risk zones.

- Allow workers to initiate SOS calls

- Provide real-time updates to supervisors and emergency responders.

When you start planning real deployments, the first question inside most factories is simple: which technology actually gives you reliable visibility inside the four walls?

BLE-Based Worker Tracking — Ideal For Indoor Visibility In A Factory

BLE-based worker tracking is built for dense, metal-heavy, multi-line environments where GPS simply fails. You place BLE gateways around the factory and give workers tags or wearables, and you get zone-level or line-level visibility without forcing them to carry bulky devices.

Key Features of BLE based RTLS system

BLE lets you translate your factory’s physical layout into precise, actionable digital zones, so every alert, report, or workflow is tied to the exact location that matters in production. Here’s a detailed look at the BLE-based manpower tracking features:

1. Zone- and Line-Level Precision

- You map BLE coverage to real production zones: lines, cells, aisles, mezzanines.

- The system tells you “Operator is at Line 2 – Packaging Cell B,” not just “inside Plant 1.”

- You can differentiate between adjacent lines or work cells even in shared open areas.

2. Optimized for Indoor, Metal-Heavy Environments

- Gateways are placed on ceilings, columns, or above lines to minimize shadow zones behind racks and machines.

- Signal handling is tuned for reflections from steel structures, conveyors, and mezzanines.

- Multi-floor support lets you distinguish between workers on ground level vs catwalks or platforms.

3. Low-Power, PPE-Friendly Worker Devices

- Tags are small enough to clip onto badges, ID cards , Wrist band , helmets, or high-vis vests without disrupting PPE.

- Broadcast intervals can be set based on risk: faster updates in high-hazard zones, slower in low-risk areas to extend battery life.

- Battery status for each tag is monitored centrally so you don’t lose visibility unexpectedly.

4. Real-Time Rules and Event Engine for Factory Logic

- You define factory-specific rules: “If a worker without training X enters Zone Y, alert the supervisor.”

- Geofences can be created around moving or temporary risk areas (e.g., a mobile crane work area).

- Man-down or no-movement events can be correlated with location: “No movement in the press line maintenance pit for 90 seconds.”

5. Forklift–Pedestrian Proximity Awareness

- BLE tags on forklifts and on workers allow the system to detect when they come within a defined distance.

- Alerts can be pushed to the driver’s display and/or the worker’s wearable (vibration, LED, sound).

- Event logs build a dataset of near-miss interactions between people and vehicles.

6. Factory System Integrations (MES, WMS, EHS, Access Control)

- Presence in a zone can be used as a signal for MES or quality workflows (e.g., “qualified inspector present at Line 4”).

- Worker entry into certain storage areas can be logged for traceability (e.g., controlled materials, chemicals).

- Access control can be policy-driven: badge allows door entry only if BLE shows user has completed specific training.

7. Scalable Across Buildings and Shifts

- The same BLE backbone supports permanent staff, contractors, and visitors with different profiles and rules.

- You can segment visibility by role: supervisors see their teams; safety sees the full site; contractors only see what’s relevant to them.

- Multi-building or campus setups can be managed from a single platform.

BLE shines when you need consistent, zone-aware visibility across production lines, warehouses, and service areas.

Indoor-Focused Worker Tracking Use Cases

BLE delivers the most value in environments where indoor precision, zone awareness, and consistent real-time visibility directly impact safety, productivity, and compliance. Across industries, manufacturing, logistics, healthcare, hospitality, labs, retail, energy, and corporate campuses, these are the scenarios where BLE shines.

Below is a quick overview of the indoor-focused BLE use cases across all industries:

Use Case | What BLE Enables | Industries |

Evacuation & Mustering | Real-time list of who is still inside; mustering status; post-event analytics | Manufacturing, offices, hospitals, warehouses, schools, hospitality |

Restricted / Sensitive Zone Access | Alerts for unauthorized entry; dwell-time logs; automated compliance records | Labs, pharma, energy sites, data centers, airports, hospitals |

Role/Skill-Based Area Control | Ensures only trained/certified individuals remain in specific zones; alerts for missing required roles | Manufacturing, utilities, healthcare, aviation, construction |

Vehicle, Robot & Pedestrian Safety | Collision-risk alerts; near-miss heatmaps; interaction tracking | Warehouses, malls, airports, hospitals, factories, large campuses |

Contractor & Visitor Oversight | Movement tracking vs permitted zones; entry alerts; billing and audit trails | Corporate campuses, data centers, hospitals, factories, construction |

Space Utilization & Flow Analytics | Heatmaps; congestion hotspots; route and dwell-time insights | Offices, retail, hospitals, education, events, industrial sites |

Once you have solid indoor visibility with BLE, the next gap appears fast: what happens to safety when workers step outside the building, beyond Wi-Fi and beacons?

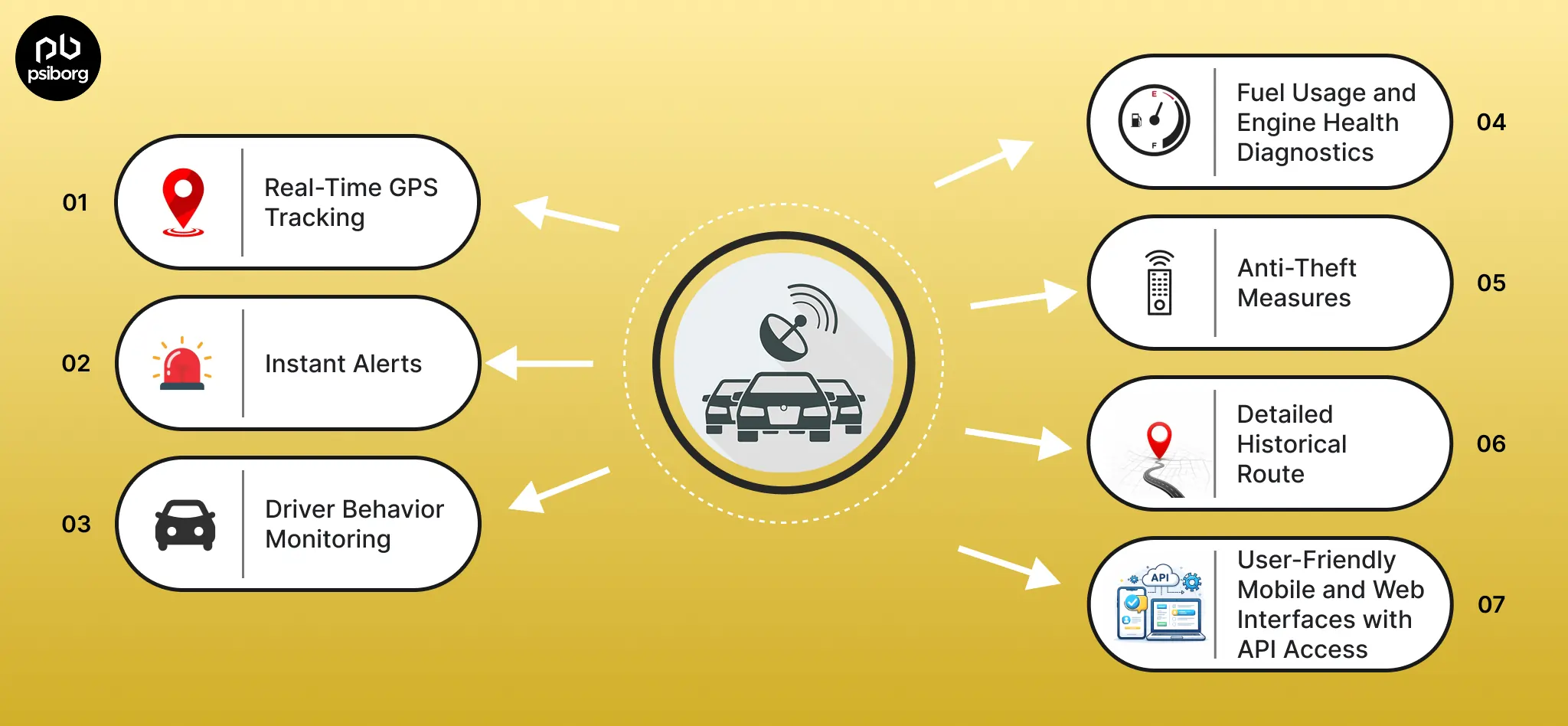

GPS-Based Worker Tracking — Perfect for Outdoor workers safety

GPS-based worker tracking is built for wide, open, and dynamic environments where BLE or Wi-Fi can’t reach, such as construction sites, utility networks, pipelines, highways, wind farms, mines, large yards, and remote facilities.

You equip workers with GPS-enabled devices and get continuous, high-confidence location and safety signals across large outdoor areas.

How GPS-Based Worker Safety Tracking Actually Works

You combine GNSS positioning with cellular connectivity so you always know where outdoor workers are and what risk they face.

- Workers carry or wear rugged GPS devices.

- Devices capture latitude/longitude, speed, heading, motion, and fall/no-motion data.

- Data flows over cellular or satellite backhaul into your safety/operations platform.

- The platform applies geofences, rules, and alerts, then surfaces them in dashboards or pushes them to apps, or control rooms.

You move from “The crew is somewhere along that 30 km line” to “Two technicians are inside the live corridor, one is stationary near Tower 14, and one triggered SOS.”

Key Features of GPS based Worker Tracking

GPS-based worker tracking delivers continuous, wide-area visibility that indoor technologies simply can’t match. Before diving into each capability, remember this: GPS gives you real-time safety intelligence over workers who operate far from supervisors, fixed sensors, or predictable environments.

Below is a concise breakdown of the features that make GPS essential for outdoor operations.

1. High-Accuracy Positioning Across Vast Outdoor Areas

- Provides reliable GNSS-level location data across fields, roads, pipelines, and remote sites

- Tracks movement, direction, and last-known location with precision

- Generates breadcrumb trails that support incident reconstruction and exposure analysis

2. Lone-Worker Protection With Real-Time Alerts

- Detects man-down, no-motion, and fall events using onboard sensors

- Sends SOS alerts with exact coordinates for immediate response

- Auto-escalates alerting if a worker fails scheduled check-ins

3. Geofencing of Hazard Zones, Job Sites & Exclusion Areas

- Defines digital perimeters around live power lines, excavation pits, tracks, blast zones, or high-voltage corridors

- Triggers alerts on entry, proximity, or overstaying in danger zones

- Logs exposure for compliance with regulatory and internal safety thresholds

4. Reliable Operation in Remote & Low-Signal Locations

- Works over cellular, satellite, or hybrid networks depending on geography

- Store-and-forward behavior ensures no events are lost during signal gaps

- Operates across forests, deserts, mountains, offshore sites, and rural grids

5. Integrated Worker–Vehicle Safety

- Connects worker identity to specific vehicles for accurate driver assignment

- Monitors speeding, harsh braking, fatigue patterns, and off-route deviations

- Continues tracking workers even after they exit the vehicle for roadside tasks

6. Faster Emergency Response & Accurate Location Sharing

- Provides pinpoint coordinates when responders need to reach an injured worker

- Highlights the nearest available responder, crew truck, or medic for dispatch

- Shares real-time GPS pins with external emergency services

7. Outdoor Route, Terrain & Movement Insights

- Identifies recurring risky routes, isolated work areas, or deviation patterns

- Maps worker density and activity across large outdoor zones

- Supports smarter deployment planning, route optimization, and hazard mitigation

When you start looking at real deployments, the value of GPS becomes clearest not in features, but in how it protects specific types of outdoor work across industries.

Common Outdoor Use Cases for GPS Worker Tracking

GPS-based worker tracking shines wherever people operate over large areas, along routes, or in remote locations where you cannot rely on fixed infrastructure or line-of-sight supervision.

Here’s a concise, cross industry use cases of GPS worker tracking solution:

Outdoor Use Case | What GPS Tracking Enables | Industries Where It Applies |

Remote Lone Worker Safety | Continuous location & motion tracking Man-down / no-movement detection. | Utilities, Oil & Gas, Mining, Security, Forestry, Remote Maintenance , FMCG , Facility Management |

Linear Asset & Corridor Work | Tracking crews along pipelines, rail lines, roads, and transmission routes. | Power Transmission, Telecom, Rail, Highways, Pipeline Operators |

Large Construction & Civil Projects | Zone-level outdoor visibility. Hazard-/exclusion-zone alerts. | Civil Construction, Infrastructure Projects, Roadworks, Commercial Builds |

Vehicle-Linked Field Crews | Linking workers to specific vehicles. Monitoring routes, stops, and roadside activity. | Field Service, Logistics, Delivery, Public Works, Emergency Repair |

Renewables & Distributed Energy Sites | Worker tracking across wide turbines and solar fields | Wind Farms, Solar Parks, Hydro Sites, Battery Installations |

Emergency & Disaster Response | Real-time crew assignment to sectors Safe vs unsafe zone tracking | Fire & Rescue, EMS, Civil Defense, NGOs, Search & Rescue |

You’ve now seen how BLE owns the indoor game and GPS dominates outdoor safety—but real decisions happen when you put them side by side.

BLE vs GPS Worker Tracking: A Comparison Table

BLE and GPS solve different parts of the worker visibility problem, and you get the best results when you’re clear about what each one is actually good at.

Use this table as a decision lens when you choose, prioritize, or combine them.

Dimension | BLE-Based Worker Tracking | GPS-Based Worker Tracking |

Best-fit environment | Indoor, dense, complex spaces (plants, warehouses, hospitals, offices, labs, terminals) | Outdoor, wide-area, distributed or remote sites (construction, utilities, renewables, roads, yards, mines) |

Indoor performance | Strong: designed for indoor use with zone/room/line-level visibility when gateways are well placed | Weak: often degraded indoors, underground, or inside steel/concrete structures |

Outdoor performance | Limited: short range; works only where you have gateways at the perimeter or in controlled outdoor zones | Strong: continuous coverage in open sky, along routes, across remote or linear assets |

Typical accuracy band | Zone/room/line level (a few meters to tens of meters depending on design and tuning) | Meter-level to tens of meters in open environments; impacted by terrain, buildings, canopy |

Coverage dependency | Depends on your installed infrastructure (gateways/beacons) and their placement | Depends on visibility to cellular network |

Battery impact | Very low power; tags can last months–years with tuned intervals | Higher power draw; frequent updates drain wearables and phones faster |

Infrastructure required | BLE gateways, beacons, power and backhaul inside buildings or controlled outdoor areas | No fixed local infra needed for positioning; you need network connectivity (cellular/satellite) and a cloud platform |

Best when you care most about… | Where exactly inside the facility a worker is, relative to hazards, equipment, and processes | Where across a large area a worker or crew is, and how they move between assets or sites |

No single technology follows people cleanly from indoor lines and corridors to yards, roads, towers, or fields. That’s where the hybrid approach comes in.

Hybrid Approaches: Combining BLE and GPS

A hybrid approach uses BLE for precise indoor visibility and GPS for wide-area outdoor safety, with a deliberate handoff strategy so you don’t lose track of workers at doors, gates, stairwells, or vehicle transitions.

A hybrid BLE + GPS system becomes essential when the way your workforce moves or operates creates visibility gaps that a single technology cannot cover.

These are the conditions that make hybrid tracking non-negotiable.

1. Workers Frequently Move Between Indoor and Outdoor Environments

Many roles don’t stay confined to a single zone. They move from controlled indoor spaces to open yards or remote areas several times a shift.

When movement happens across boundaries, neither BLE nor GPS alone can maintain continuous visibility.

2. Both Indoor and Outdoor Areas Carry Significant Safety Risks

Some risks, like vehicle interactions, restricted zones, or confined spaces, occur indoors.

Others, like lone-worker hazards, corridor-based work, and remote travel, occur outdoors.

If both environments present credible risk, each requires the technology designed specifically for that setting.

3. You Need a Single, Continuous Safety Timeline With No Location Gaps

Safety teams must see exactly where a worker was before, during, and after an incident.

If location tracking drops when someone steps through a doorway, gate, tunnel, loading bay, or semi-covered area, you lose the critical context needed for investigation, response, and compliance.

Hybrid ensures there are no “black holes” in the worker’s movement history.

You’ve compared BLE and GPS side by side. Now it’s time to convert that insight into a practical selection framework, one your operations, safety, and IT teams can actually use.

Choose the Right Worker Tracking Solution for Your Business

Selecting BLE, GPS, or a hybrid system isn’t about choosing a “technology.” It’s about understanding where your real risks occur, how your workforce actually moves, and what level of visibility supports safe, efficient operations.

Indoor-Dominant Operations (BLE-First)

If most risks occur inside controlled spaces, like lines, rooms, aisles, wards, or labs, and workers rarely leave the building, you need room- or zone-level visibility, making BLE your primary tracking layer.

Outdoor-Dominant Operations (GPS-First)

If major risks occur across open, remote, or route-based environments, like lines, towers, yards, pits, or fields, and workers operate out of supervisor line-of-sight, GPS becomes the more reliable and primary technology.

Conclusion

Choosing the right worker tracking system isn’t about picking BLE or GPS, it’s about matching real-world worker movement, risk geography, and operational constraints to the technology that delivers uninterrupted safety visibility. BLE gives you precision indoors; GPS gives you coverage outdoors; and hybrid architectures ensure no blind spots as people move between environments.

If you’re unsure which tracking model fits your site, workforce, or regulatory needs, PsiBorg can guide you through every step.

Psiborg is an IoT solution provider and our IoT consultation includes analyzing your risk geography, mapping worker movement patterns, assessing device and infrastructure constraints, and designing a custom BLE, GPS, or hybrid architecture tailored to your operational realities.

FAQs

The best solution depends on your risk geography: BLE for precise indoor visibility, GPS for outdoor coverage, and hybrid systems when workers frequently move between indoor and outdoor environments.

BLE provides accurate zone- or room-level tracking indoors, while GPS delivers wide-area, satellite-based tracking outdoors. Each excels in different environments and is often combined for uninterrupted visibility.

Workers carry BLE tags or wearables that communicate with fixed gateways, enabling real-time indoor location, zone transitions, dwell times, and proximity-based safety alerts in controlled spaces.

Yes. Hybrid systems use BLE indoors and GPS outdoors, automatically switching between technologies to ensure continuous, gap-free visibility across buildings, yards, corridors, and remote sites.

Industries with complex safety risks, including manufacturing, logistics, utilities, construction, oil & gas, healthcare,Facility management, FMCG and security, gain the most value from enhanced visibility, faster response, and stronger compliance.