Coal mining is one of the most hazardous and arduous tasks known till date. The process of mining puts at stake the miner’s security; it challenges the miner’s mental and physical capabilities at each step. As technology is taking leaps and bounds to improve human beings’ overall lifestyle this IoT based Coal Mine safety Monitoring system is a topic that is garnering people’s attention.

If you are wondering how can IoT be a game-changer for the mining industry this blog is your right place to be. The following blog explores the role of IoT in coal mining. But before unraveling the concept of IoT in coal mines let us first understand the meaning of IoT.

INTERNET OF THINGS (IOT)

IoT is anything and everything that has sensors and processing abilities to connect and exchange data. It simplifies the process of connection; These smart devices are controlled and managed by IoT dashboards or IoT Mobile Applications.

In the modern era the magic of IoT is omnipresent; it is regulating factories; shipments; data centers and web analytics (all from a click to activate the IoT model). So IoT is a simple concept that is building powerful mechanisms; let us dive into the next section of the blog to understand how IoT is becoming a game changer in the coal mining industry.

IoT market worldwide is estimated at $622 billion (in 2020). (Source – Global Data )

At present companies like Cisco, Siemens, AT & T, Reliance Jio and Verizon are exploring the use cases of IoT in the mining industry.

IOT BASED SAFETY MONITORING SYSTEM FOR COAL MINES

Miners all around the world work in extreme conditions; working in blocked coal mines; under the extreme presence of methane; to extract coal. While miners put their life at stake; the strong IoT mechanisms can be integrated to help them in getting safety alerts right in time.

IoT based coal mine safety monitoring system is comprised of sensors , which communicate over a low power communication protocol such as LoRa and send data to a central IoT gateway , where collected data is analyzed. This data can be seen locally on the LCD screen connected with the IoT gateway or can be further sent to cloud through internet. Data fetched from cloud can be seen on our mobile devices , laptops etc.

SENSORS USED IN IOT BASED COAL MINE SAFETY MONITORING

There are several sensors that are used in IoT based coal mine safety monitoring and push alerts when a required parameter goes beyond threshold values. The following sensors are used to monitor different parameters to enhance the safety of coal mine.

TEMPERATURE AND HUMIDITY SENSORS

The temperature sensor measures the temperature in the mining area. And humidity sensors measure the humidity level within the mines. If temperature or humidity exceeds threshold values , notifications and alerts are generated, which can turn on exhaust fans or increase the speed of fan accordingly.

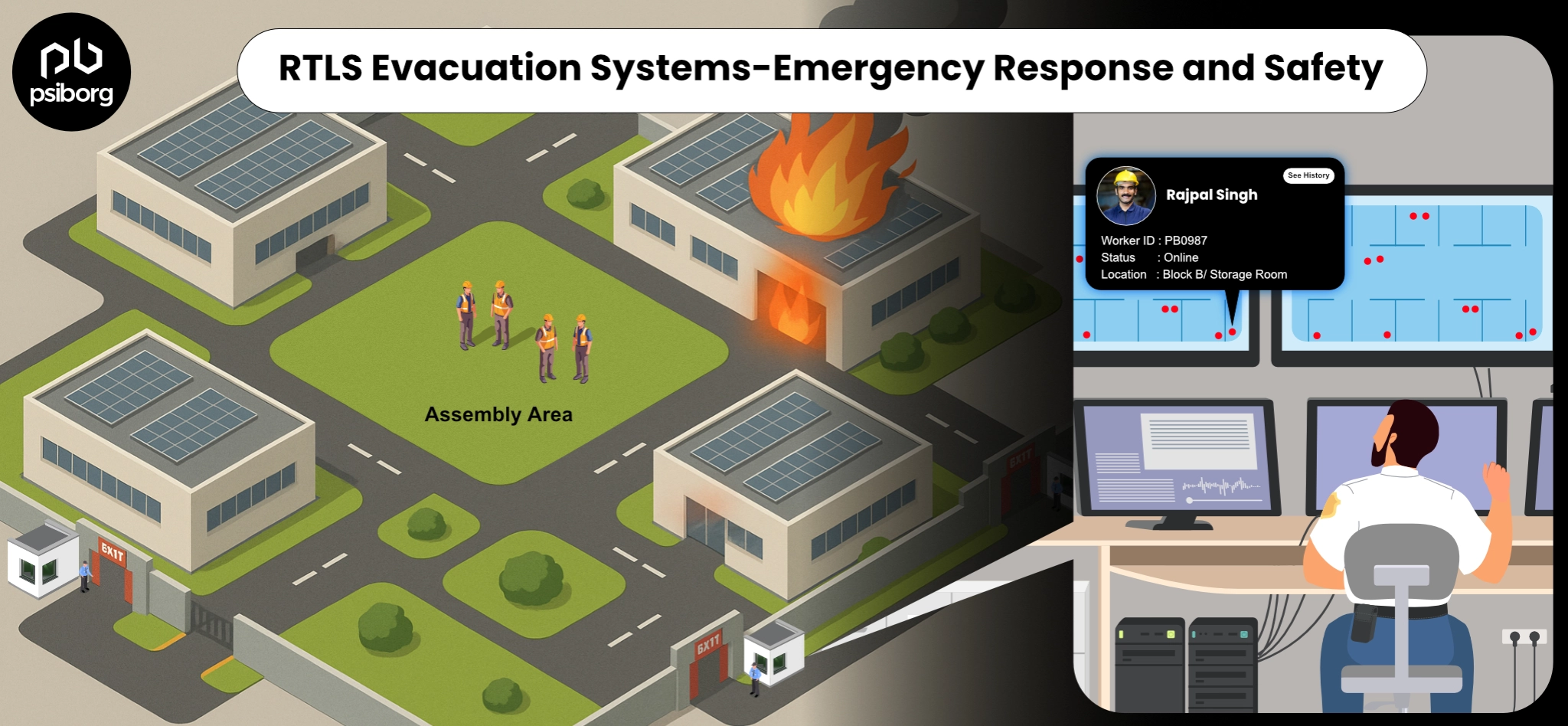

LOCATION AND PROXIMITY SENSORS

Proximity sensors help in locating miners and heavy equipment within the mine. Miners use this information to protect fellow miners from accidents that could potentially cost lives.

VIBRATION DETECTION SENSORS

While vibrations are also a key determinant to noticing the change in mining levels; these sensors also play a key role by checking the intensity of vibrations and alerting the miners right in time. Vibration sensors can notice the minutest changes in the mining patterns.

HARMFUL GAS DETECTION SENSORS

Methane is the number one killing agent in coal mines if miners are alerted on time at least a thousand lives can be saved in a year. These sensors measure the quantity of contamination at the exact location and adjust the ventilation system accordingly. Electrochemical sensors are mostly used to measure gases in the environment.

IOT DASHBOARD FOR MONITORING COAL MINES

To make the mechanism of sensing vibration, temperature and other aspects a reality an LCD screen is employed to display the changes measured in sensor values.

With the supplied power, sensors collect the data and this collected data is sent to the IoT gateway. The data is further displayed on the local system (without internet access) which is directly connected to the IoT gateway. This system checks for parameters including gas quantity, gas pressure, temperature, and vibrations.

An alarm is attached closely to the LCD screen; the LCD screen alerts the miners right in time when any of the sensor values go beyond the threshold.

This IoT gateway, if provided internet access, sends data to the cloud server. From where data can be analyzed and viewed remotely from anywhere in the world.

WHY IS IOT BASED COAL MINE MONITORING REQUIRED?

The IoT system mechanism can actually keep the miner’s safety in check. A machine integrated with the chip system can alert people right in time. In the times when IoT is creating a sensation by empowering multiple industries its role in coal mining is also a breakthrough revelation.

Wires and other parts that connect the underground cable to the main mining center were practices that proved risky for miners. Most of the time miners were caught up in the wires which resulted in a loss of life. As the times changed and everything was just within the power of a click, so simplified, became the process of data management and miners’ safety.

The IoT system involves alerting the workers right in time to protect and prevent them from any sort of mishap, mostly wirelessly.

Conclusion

The integration of sensors in IoT devices is one way to monitor the safety of workers. There are several other management systems that can be built with the mix and match of IoT devices, presently industries are harnessing the power of IoT complied with Artificial Intelligence and edge computing.

There’s a lot many ways in which IoT will explore the unexplored long sought of dream of mining with safety can be a reality someday with the power of IoT.

At PsiBorg , We are an IoT product development company and have immense experience in working with wireless sensor network systems. If you are looking to develop one, you can connect with us.