Remote Monitoring and Control: View Data Like Never Before

- Home

- Success Stories

- Remote Monitoring and Control: View Data Like Never Before

Noida, Uttar Pradesh

Automation

Maintenance monitoring, Compliance monitoring, Fleet tracking

Project Highlights

- DSS partnered with PsiBorg Technologies to develop a remote monitoring and control solution for efficient and reliable analysis of data collected from all industrial devices.

- PsiBorg developed an IIoT dashboard, allowing remote monitoring and control. The solution provides accurate and reliable data that can be monitored remotely to optimize the production process.

- This web-based IIoT dashboard for online remote monitoring displays a real-time graph showing the current value, which can also be downloaded by selecting specific parameters.

- The alarm on the dashboard displays all current and past alarms that have been triggered when certain devices have exceeded the threshold set for them.

- With the IIoT dashboard, we automated data monitoring and analysis tasks. This has allowed the company to reduce costs, improve decision-making, and improve customer service.

About the Project

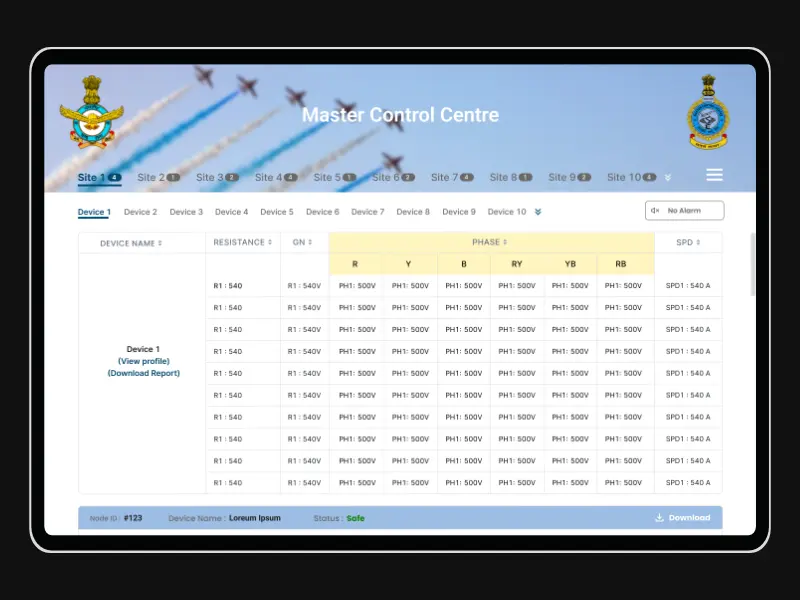

Our client, DSS, faced challenges in monitoring and analyzing the data collected from industrial devices. PsiBorg developed a Master Control Center as an online remote monitoring and control solution. The Master Control Center is an IIoT Dashboard for data visualization and monitoring. The data monitored was for different industrial instruments which includes parameters such as Ground-Neutral voltage, Temperature, humidity, SPD, Phase voltage etc.

It is a web-based application connected to the client’s MongoDB server, which has already stored the data for industrial devices.

The goal behind building the dashboard was to remotely monitor and analyze the data in real-time and to generate alarms based on set threshold values.

As interesting and innovative as the project sounds, its development was quite intricate but achievable.

Our Innovative Solution

To overcome the challenges and improve the efficiency, reliability, and cost-effectiveness of the process, our team developed an IIoT- dashboard that can be accessed on the company’s intranet.

Our main objective here was to –

- Offer online remote monitoring and control solutions to analyze data in real-time and minimize downtime and maintenance issues.

- Provide error-free and reliable data to optimize the production process and improve efficiency.

- Refine decision-making by offering real-time data analytics like weekly/monthly/and yearly reports.

- Upgrade customer service by providing real-time visibility into device performance.

To achieve all this, our team developed a web-based IIoT dashboard and connected it to the company’s MongoDB database server.

The dashboard was designed to be accessed on the company’s intranet, thus allowing users to view and analyze the data from anywhere on the company premises.

The “Master Control Center” architecture includes a set of sensor nodes that collect data, a gateway that connects the sensor nodes to the backend, a backend that stores, processes, and analyzes the data, a web-based front-end application for the user interface, and a notification service that sends alerts and other notifications to the users.

Features

1

Real-time Remote Monitoring

The IIoT dashboard gives real-time insights on the workings and health of industrial devices. The supervisors can monitor the working performance of the device remotely from anywhere.

2

Predictive Maintenance

The detailed IIoT device information provided by the remote monitoring dashboard helps in predicting the repair needs of industrial devices, thus allowing for proactive maintenance.

3

Data Visualization

The remote monitoring dashboard shows data in a simple, easy-to-understand forms, such as tables, charts, and graphs. Users get customizable reports to track performance.

4

Remote Access

Users can access the IIoT device information on the dashboard from anywhere, using any device, be it mobile phones, tabs, or laptops.

5

Anomaly Detection

The remote monitoring dashboard identifies any deviations from the set threshold and alerts the users about potential issues.

6

Integration Capabilities

This remote monitoring dashboard can be easily integrated to any industrial system, sensors, and databases.

Technology Used

We at PsiBorg are a click away. Please mail to us at info@psiborg.in

Just in case you need to understand anything and everything about IoT, Project requirement.

Projects Challenges

The client was facing challenges with monitoring and analyzing the data gathered from industrial devices. After all, the standard method of data monitoring and analysis is labor-intensive and time-consuming, leading to costly downtime and maintenance.

Also, accessing the data on a large scale is a challenging task. As with the limited data analytics capability, it gets difficult to identify patterns and flaws, and thus hinders the decision-making process.

However, IoT has answers to all your problems. With an IoT dashboard, the company can optimize production processes, increase efficiency, reduce costs, avoid unforeseen downtime, and productivity loss.

Result

Master Control Center was one of the IoT Dashboard projects, in which our team was already experienced.

We developed an IIoT dashboard that monitors resistance, GN, phase, and SPD.

We successfully deployed a fully working IIoT- dashboard to the client under the mentioned timeframe, thus fulfilling the client’s needs.

At PsiBorg Technologies, the developers are highly skilled and experienced enough to work on projects with varied difficulty levels

The Master Control Center is one example where we developed an IIoT dashboard for online remote monitoring and control with the latest technology to access data in real-time flawlessly on any screen size.

What We Delivered

- Node Devices

- Gateway

- GN Meter

- 3 Phase Voltmeter

- Earth Resistance Sensor

- Surge Protection Device [ SPD]

- Web Application: Admin Control Panel

Client Testimonial

━ DSS Digital Equipment Protection Co.

“Our partnership with PsiBorg Technologies was a game changer. With their developed IIoT dashboard, we were able to make our production process more efficient. The dashboard works smoothly, they delivered a quality product on time, and I appreciate their work ethics.”