Heat detection in cattle is the most important factor in dairy farming. It is one of the most crucial factors that determines the reproductive performance of the dairy herd and ensures profitability in the dairy business.

As it happens, there are already many use cases of smart agriculture system, one of which is heat detection in dairy cows.

If you are active in the field of agriculture and the dairy industry, you must be aware of all the technological advancements occurring in the dairy industry. However, one aspect of this advancement that caught our attention the most is the detection of the estrous cycle in cattle.

So, IoT based estrous detection in cattle is carried out to improve the artificial insemination (AI) results, reduce the insemination cost, and ensure shorter calving intervals without much labor inputs.

Here at PsiBorg, we create a smart IoT based cattle health tracking and monitoring system. These systems give high success rates for artificial insemination, automate the detection of the estrous cycle in cattle, and boost the profitability of a dairy business.

This blog aims to provide all the information you need to know about cattle heat detection devices, including their functions, the problems they fix, and why a dairy business should use one.

So, let’s explore heat detection in cattle using IoT technology in detail.

Why Timely Heat detection is important?

Heat detection is the act of monitoring the events of the estrus cycle in cows so that Artificial Insemination (AI) can be carried out timely.

However, for a successful pregnancy, the cow must be inseminated at an appropriate time of ovulation, that is, 8-13 hours before ovulation.

The ovulation phase in cows occurs for approx 10-12 hrs and if the farmer fails to detect the estrous cycle or fails to bring the cow on time for AI, they will have to wait for another cycle and meanwhile, it will be a significant waste of time and also a loss for their dairy business.

The reproductive performance of dairy cows, which is primarily dependent on their ability to accurately detect heat and use their estrus cycle, is one of the significant factors influencing the productivity and profitability of dairy farming.

Therefore, timely heat detection and successful insemination lead to higher conception rates and shorter calving intervals.

But also the standard approach of detecting heat period in cows involves manually monitoring the cow’s behavior like sniffing or chin resting other cows, mounting, decreasing feed intake, or other secondary visual signs.

To detect cow’s behaviour it is required to look two or three times a day for around 30 minutes, and involves good record keeping and training.

This method of requiring a human to continuously watch over these behaviors is very laborious and prone to mistakes and avoidance.

That is why, there is a need to automate timely heat detection.

When anything requires real-time tracking or monitoring then IoT is the answer.

How Heat detection help in successful Artificial Insemination in cattles?

So, in dairy farms, artificial insemination is performed to make cows pregnant. For the dairy business, the best way to increase business profit is by improving the reproductive performance of the dairy herd.

The estrous cycle in cows is 17-24 days, and even if a single heat period in a cow is missed or a failed AI results in 21 days of loss in production. This number can even be compounded further if artificial insemination (AI) is carried out on a cow that doesn’t show any heat signs.

Moreover, in a dairy farm, the measurement of calving interval (CI) tells about herd performance. Generally, the CI is 12 months. Failed AI can lead to an increased Calving Interval (CI).

An increased CI also means decreased overall milk production, which is also equivalent to reduced dairy income and additional semen costs.

Accurate heat detection maximizes the success of AI in cattle because it allows insemination to occur at the optimal time within the cow’s estrous cycle.

Inseminating the cow too early or too late can significantly reduce the chances of conception. Therefore, timely detection of heat ensures that insemination is performed when the cow’s reproductive tract is most receptive to fertilization, maximizing the chances of pregnancy.

In addition, successful heat detection in dairy cattle helps to shorten the calving interval (CI), increasing the efficiency of AI programs and allowing farmers to make their breeding plans more effective. This can lead to improved genetic progress and herd productivity over time.

Current Challenges in the Dairy Industry

In the dairy industry, challenges related to heat period detection include:

Accuracy:

Making sure that cows’ heat phases are accurately detected. Because if subtle signs are missed or misinterpreted, this could result in incontinence and lower conception rates.

Manual Task:

Detecting heat through manual observation can be labor-intensive and expensive to run, particularly in large herds where skilled workers are needed.

Variability in Signs:

Not all cows exhibit clear and consistent signs of estrus, leading to difficulty in accurately identifying heat periods, especially in some individual animals.

Overcoming these challenges requires technological advances, such as the development of more accurate and user-friendly heat detection solutions, as well as education and training programs to help dairy farmers adopt and effectively use these technologies.

The solution to heat detection problem- IoT cattle health monitoring system

At present time, an IoT based cattle heat detection device is the only accurate and highly effective solution for heat detection in cattles.

PsiBorg has developed IoT based livestock monitoring system by keeping in mind the various challenges faced by dairy farmers and dairy businesses.

The cattle health monitoring system includes smart animal wearable devices that detect the onset of the cattle’s heat.

The wearable device is embedded with key sensors to continuously monitor body temperature, heart rate, respiration rates, activity levels, and even rumination patterns.

These sensors from the wearable device transmit data wirelessly to a gateway. The gateway sends the data to the cloud. Advanced algorithms analyze the collected data in near real-time and identify patterns or any deviations from normal values.

Dairy farmers receive an alert on the mobile app/ IoT dashboard when a cow’s health parameter deviates from the pre-set thresholds.

How Cattle health monitoring system detects oestrous cycle?

When the estrous cycle begins, a cow experiences a number of behavioral changes that are picked up by the aforementioned cattle heat detection device.

Nonetheless, a smart neck collar, identifying primary and secondary heat signs, and monitoring rumination patterns are all part of an IoT-based heat detection technique.

1. Smart Neck Collars

These collars are equipped with sensors that track various aspects of a cow’s activity.

Key data points include:

Movement: Increased restlessness, walking, and mounting activity during estrus.

Posture: Sensors can detect changes in posture, indicating “standing to be mounted,” a strong sign of estrus.

2. Heat Period Detection Signs

Standing Heat: It’s the primary sign of heat period detection. This is the definitive and most reliable sign of estrus. It occurs when a cow stands still and allows other cows to mount her.

However, there are also some secondary signs, that might be present before, after, or during the heat period such as:

Increased activity: Restlessness, frequent walking, mounting other cows.

Vocalization: Excessive bellowing or mooing.

Reduced appetite: May eat less or appear off-feed.

Tail behavior: Raising the tail, holding it to the side, or having mud or manure smeared on the tailhead due to mounting activity.

Chin Resting: During estrus, cows may rest their chin on the rump or back of another cow.

3. Comparison between Heat period and Rumination

Rumination pattern is also one factor to look for while detecting heat periods in cows. Because heat detection and rumination are linked through behavioral observations.

When in the heat period, cows exhibit altered rumination patterns, such as decreased chewing time, due to increased activity associated with seeking a mate.

Therefore, monitoring rumination changes can also help in identifying cows in heat. Thus, rumination serves as a behavioral marker for heat detection, offering insights into reproductive status alongside its role in digestion.

Benefits of a Smart Cattle Heat Detection System

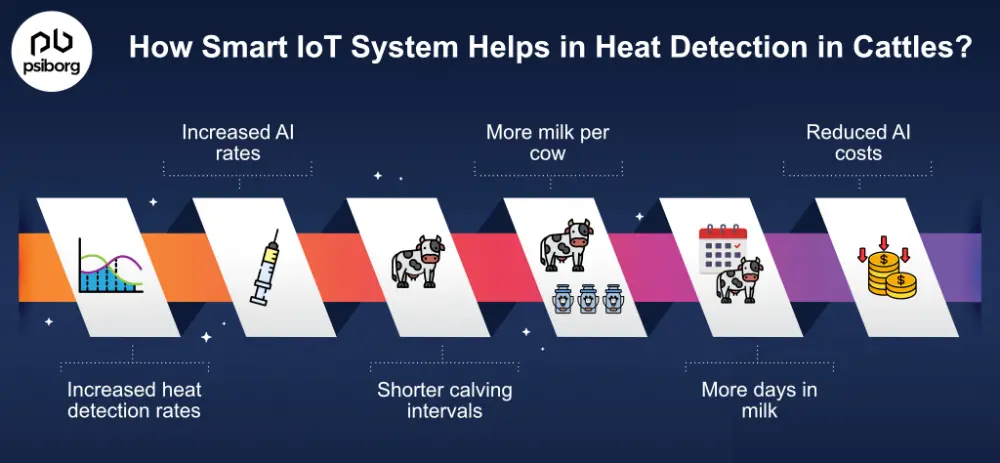

Increased heat detection rates

The smart IoT system offers 24/7 monitoring and identifies even subtle behavioral changes indicating heat, thus leading to earlier insemination opportunities. Plus, it also eliminates the possibility of mistaking non-estrus behavior for heat, leading to more targeted interventions.

Increased AI rates

Accurate heat detection allows for insemination at the peak fertile window, maximizing the pregnancy chances. Additionally, it minimizes the risk of missing short or subtle estrus cycles, leading to more pregnancies per year.

Shorter calving intervals

Early heat detection leads to timely insemination and shorter gestation periods. Shorter calving intervals contribute to increased milk production and overall herd profitability.

More milk per cow

As mentioned above, Shorter calving intervals allow for more lactation cycles per cow, leading to higher overall milk production.

More days in milk

Shorter calving intervals ensure cows spend more time lactating, leading to increased milk production. Also, early pregnancy confirmation allows for strategic planning of dry periods, maximizing milk production potential.

Reduced AI costs

Accurate heat detection minimizes unnecessary inseminations, reducing semen and labor costs. Increased AI success rates lead to fewer repeat inseminations, saving time and resources.

To Sum Up,

Increasing profit in the dairy business is only possible with the improved reproductive performance of the dairy herd.

However, when looking at the fertility performance of a dairy herd, it is important to remember that heat detection can be challenging, but investment in time or automation can help to improve performance.

PsiBorg Technologies develops an IoT based cattle health monitoring system that makes the hectic process of heat detection in cattles significantly simpler and more efficient.

To know more details about the working of smart heat detection techniques and how it can benefit your dairy business, get in touch with us.

About the Project

FAQs

The traditional techniques of heat detection include visual observations, chin resting, and tail behavior. However, these techniques are prone to human errors. That’s why the most accurate technique for heat detection at present time is a smart heat period detection system in cattles. The system comes with smart neck collars to detect even the subtle estrous cycle changes in cows that might go unnoticed by the human eye.

So, a smart system for heat detection in cattle includes smart neck collars and pedometers. These smart devices track and monitor a variety of cow behaviors, such as restlessness, frequent walking, mooing, mounting other cows, and many others. In addition, they also create real-time alerts that tell farmers when it is appropriate to artificially inseminate their cows.

Some of the heat indicators for cattle to detect whether the cow is on an estrous cycle or not are restlessness, increased walking, loud mooing, chin resting, standing, mounting over cow, decreased rumination, and reduced appetite.

Getting an accurate signal for the onset of the heat period in cattles is important to perform successful artificial insemination. Nonetheless, all the dairy farms perform AI to make the cows pregnant.

Moreover, in a dairy business, the profit is only achieved by improving the overall reproductive performance of the herd which is responsible for overall milk production.