We really like how smartphones have changed our routine lives, right? Now imagine the same happening in different workplaces; the production and processes get optimized without human intervention. This futuristic concept is called the Industrial Internet of Things (IIoT) which is a total game-changer. This technology connects all machines, sensors, and software so that everything becomes automated and decisions can be made with the data in hand. The operations get smarter, faster, and more efficient, making IIoT a critical component of Industry 4.0. But what makes it so revolutionary? What incredible benefits does it bring? Let’s find out!

What Is IIoT?

In simple words, it is a promising extension of IoT technology into different industrial environments. It efficiently connects machines, sensors and devices to fetch real-time data for analysis. While IoT works more for enhancing personal convenience, IIoT is suitable for large-scale applications in sectors like manufacturing, energy, healthcare, etc. It uses advanced analytics and automation to help industries improve their operations and output and increase safety. As a key part of Industry 4.0, IIoT has a big role to play in how businesses manage resources, make important decisions and achieve competitive productivity in today’s digital world.

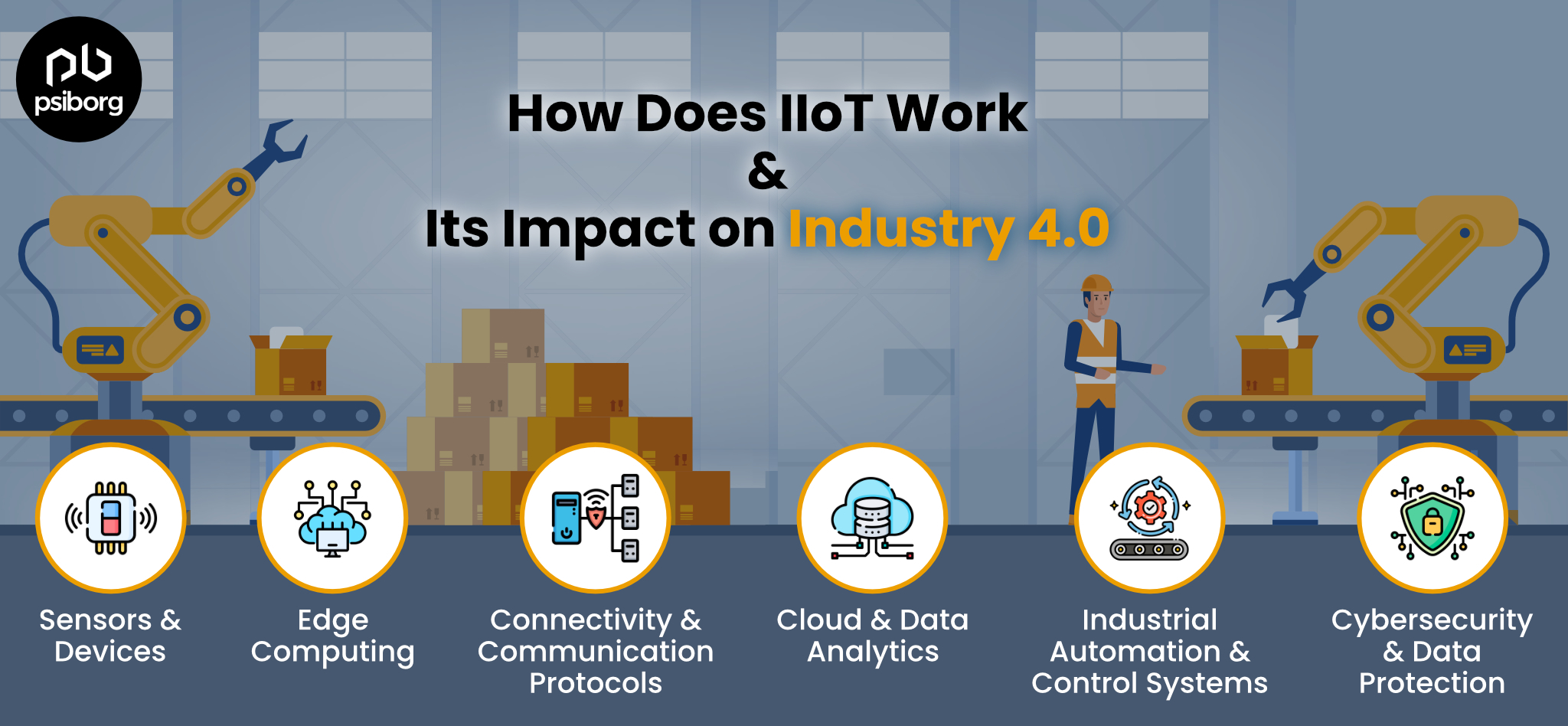

How Does IIoT Work?

Now comes the most awaited part, where we unveil how does IIoT works. Basically, it puts together advanced connectivity and data analytics to integrate smart automation in industrial settings. Here are the main components:

Sensors & Devices

IIoT starts by implanting smart sensors embedded in industrial equipment to collect various data like temperature, pressure, vibration, humidity etc.

Edge Computing

It uses the data to process it to its best. No raw data is sent directly to the cloud. That’s how businesses can get real-time responses for their critical processes.

Connectivity & Communication Protocols

Different communication protocols like MQTT, OPC UA and industrial Ethernet are used to transfer data between devices and the cloud.

Cloud & Data Analytics

Once data is transferred, it goes through advanced analytics so it’s ready to share valuable insights, detect problems and look for potential failures.

Industrial Automation & Control Systems:

This processed data is used by automated control systems like SCADA (Supervisory Control and Data Acquisition to boost machine performance and reduce human intervention as much as possible.

Cybersecurity & Data Protection

IIoT systems also include cybersecurity practices like encryption and authentication to protect industrial networks from unwanted and harmful cyber threats.

Key Technologies in Industry 4.0 Backed by IIoT

Thanks to Industry 4.0, multiple sectors now have IIoT-powered smart and connected systems that increase efficiency and reduce downtime.

1. Smart Factories –

These production facilities have IIoT-driven machinery and systems. Everything is automated and interconnected to make the manufacturing process smooth. Smart factories are all about improving operational efficiency and reducing errors with the help of live monitoring.

2. Digital Twins –

It’s basically a virtual replica of a physical asset. It enables real-time monitoring, Data-driven predictions and performance improvement. Manufacturers, especially, use this technology to make potential changes in production processes instead of the actual ones.

3. Predictive Maintenance –

This advanced forecasting uses sensor data and AI to detect early signs of damages or issues in machinery. By catching the wear & tear before it causes breakdowns, businesses can actually extend the lifespan of the equipment.

4. Augmented Reality (AR) & Robotics –

AR helps workers with the required information, simplifies & improves training and reduces errors. Then, there are robotics that automate tasks to avoid repetition. Together, they both make work easier, faster, and more accurate!

Benefits of IIoT

It’s difficult not to be impressed by the many advantages IIoT offers across industries for improved efficiency, cost savings and better decision-making.

Better Operational Efficiency

Since it involves real-time monitoring and automation, there are eventually fewer human errors and the workflows are all optimized.

Predictive Maintenance & Reduced Downtime

The power of AI helps in identifying if there can be any machine failures so it can be fixed n time. This brings downtime to a minimum.

Improved Safety & Compliance

The sensors connected to the system closely monitor dangerous conditions in the premises. It’s made sure that worker safety is not compromised and all guidelines are followed.

Cost Reduction & Energy Efficiency

As we know, IIoT-powered systems ensure the best use of resources, which leads to optimum energy consumption and reduced operational costs.

Streamlining the Supply Chain

Real-time tracking of goods and assets helps a lot with shipping and handling. Businesses experience a lot fewer delays and logistics become more efficient.

Data-Driven Decision Making

IIoT offers up-to-the-minute insights that can’t be topped when it’s about making big decisions. It also helps companies with their strategic planning and improving performance.

Industries Benefiting from IIoT

So many industries today are making the most of the innovation and efficiency of IIoT. Here are some key sectors making the smart move:

1. Manufacturing:

With smart factories, the manufacturing sector is now experiencing automated production lines, reduced operational costs and real-time quality control. It has now become very easy to detect defects, minimize errors and achieve product consistency.

Suggested Reading: IoT in Manufacturing Industry

2. Energy & Utilities:

IIoT here has led to the implementation of smart grids that support efficient distribution of energy. It’s possible to monitor power plants from anywhere and anticipate the need for maintenance. This reduces the risk of unexpected failures and increases cost savings and sustainability.

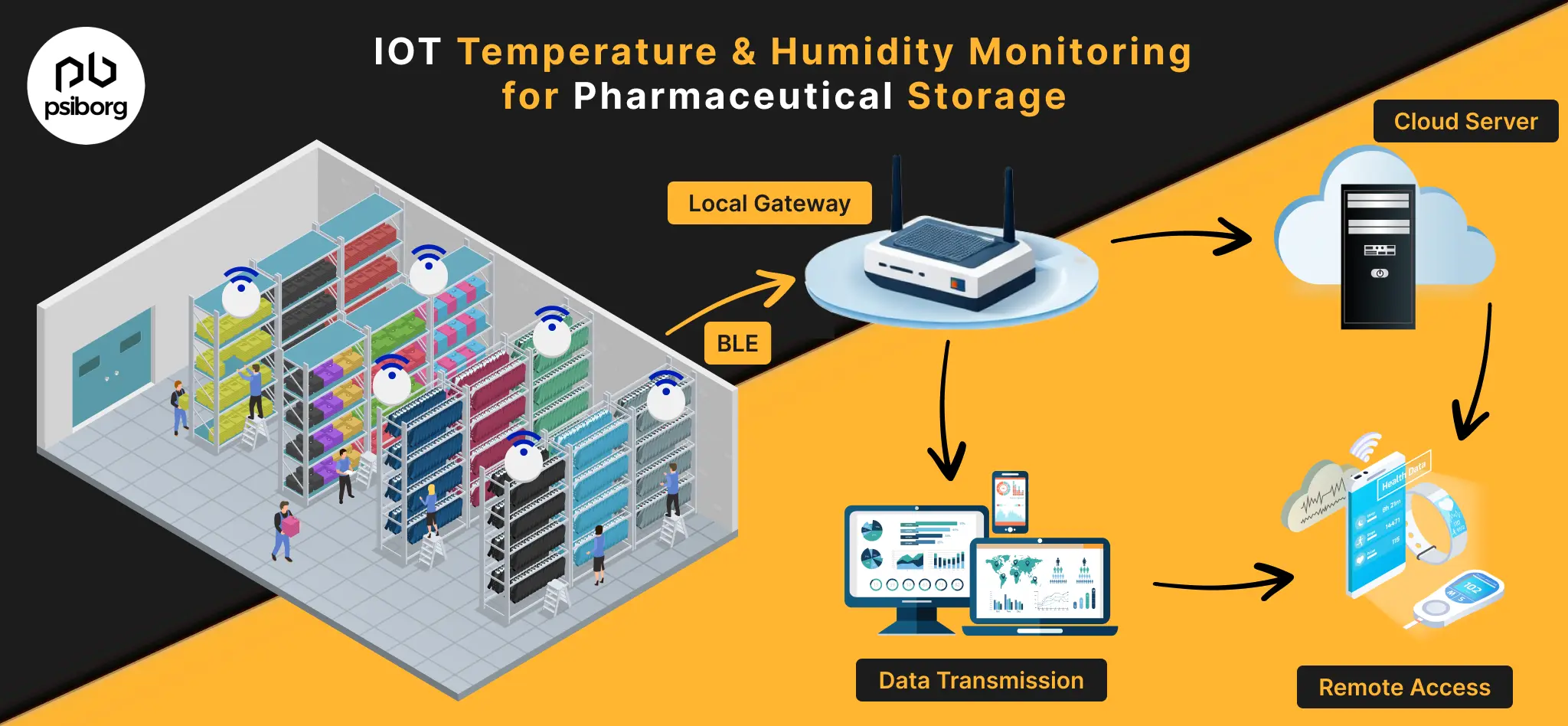

3. Healthcare:

The healthcare industry uses IoT-enabled medical devices for remote patient monitoring. Doctors can now check vitals and manage chronic conditions better than ever. Then there are smart hospital management systems that improve overall patient care.

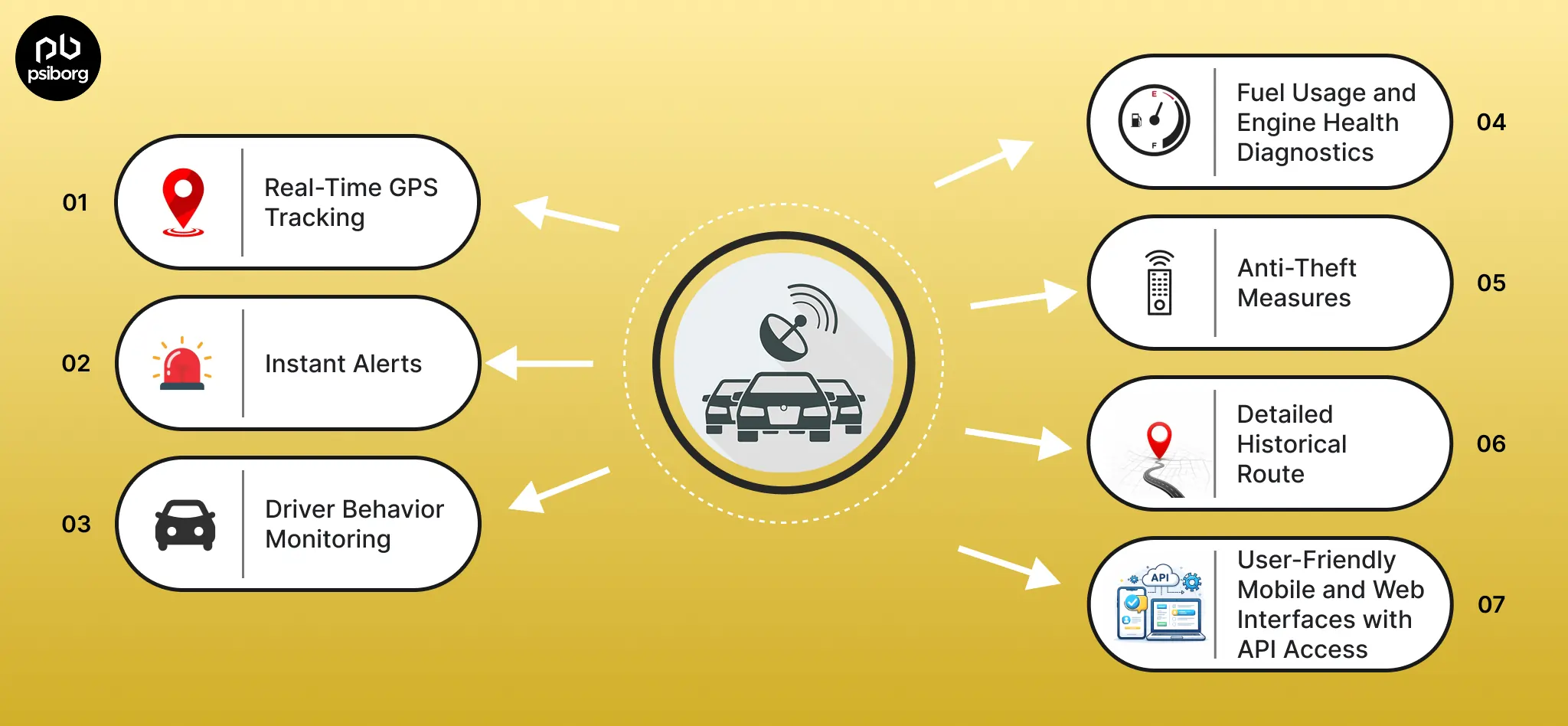

4. Transportation & Logistics:

These companies use IIoT for fleet management. The technology ensures proper route planning and live vehicle tracking. They have seen quite an improvement in supply chain operations and fewer losses.

5. Agriculture:

The experts in the field are now judiciously using water and fertilizer as per real-time soil conditions. They use smart irrigation and employ precision farming techniques to monitor soil and weather conditions. This ultimately improves crop yield and sustainability.

Challenges in IIoT Adoption

Cybersecurity Risks

– It has become extremely important to protect IIoT networks from cyber threats.

Interoperability Issues

– A lot of thought goes into how to ensure smooth communication between multiple IIoT devices and platforms.

High Initial Investment

– While the technology comes with long-term savings, initial setup costs are often huge.

Data Privacy & Compliance

– It again takes a lot of time and resources to securely manage the massive industrial data.

Future Trends in IIoT

AI & Machine Learning

– Automation and predictive maintenance will get even better with advanced algorithms.

5G Connectivity

– Faster and more reliable internet connections will enable industries to use smart technology more widely.

Edge Computing Expansion

– Dependency on the cloud will be reduced and real-time analytics will be on the spot.

Digital Twin Technology

– This will come in handy for simplifying industrial processes at various levels without having to spend a lot.

Conclusion

The IIoT is certainly a major part of Industry 4.0 that has brought a successful revolution to various sectors. While there are a bunch of challenges, tech advancements will continue to drive IIoT innovation. Further, it will continue giving an edge to the early adopters.

FAQs

IIoT is the connection of all machines and equipment in a huge setup via super-fast Internet. They are brought together for real-time data sharing, preventing downtime and working together more efficiently.

IoT is mainly useful for everyday life. You can see it working in smart home devices and fitness trackers. On the other hand, IIoT is for industries and makes sure that factories and plants run effectively. It helps with heavy-duty tasks and focuses on large-scale operations.

IIoT includes smart sensors that gather data, fast connectivity for quick information sharing, edge computing for data process data quickly and automation systems for acting on it. This valuable data is protected with cybersecurity.

It helps in making factories and businesses more computerized and connected. With smart machines, predictive maintenance, digital twins and other technology, it makes work faster, safer and with minimal errors.

IIoT has proved to bring down costs, prevent machine breakdowns, improve safety and boost production. Further, by providing real-time insights, it also facilitates decision-making and operational efficiency.