Running a production industry can be tricky with so many tasks happening at the same time. An IoT Production Monitoring System helps you to keep track of everything in real-time from equipment performance to worker activity and energy use.

In this blog, we’ll learn what a Production Monitoring System is, why it’s becoming more essential in industries along with its features, key benefits, and use cases in detail.

What is an IoT Production Monitoring System?

A Production Monitoring System is a technology-driven approach to track and optimize manufacturing operations. It continuously collects data from equipment, workers, and production lines to give real-time updates on the production process.

In simple terms, it’s like having a virtual supervisor who never takes a break, ensuring that everything runs smoothly.

Why Do You Need a Production Line Monitoring System?

Let’s explore why this system is crucial for improving operations and performance in industries are defined below:

- An IoT production line monitoring system in industries like manufacturing and construction helps to track equipment usage, performance, and maintenance. It ensures everything runs smoothly by providing timely servicing to prevent unexpected breakdowns. This leads to less downtime and fewer production delays.

- Moreover, In industries like food manufacturing, and pharmaceuticals maintaining the right temperature and humidity levels is crucial. The systems track environmental conditions in real-time to prevent product spoilage or damage.

- Additionally, the system is crucial to track energy consumption and identify inefficiencies. In the manufacturing industry, it helps to optimize energy use across machines, which promotes sustainability and lowers operational costs.

- Overall, it tracks worker productivity, attendance, and time spent on tasks. In construction sites, it ensures that workers are present as required and working in the right areas. This improves safety, minimizes delays, and makes operations more efficient.

How Does an IoT Production Monitoring System Work?

Let’s understand how a IoT based production monitoring system operates:

Workers or equipment in the production area are equipped with sensor tags that collect data such as equipment performance, environmental conditions, or worker activities.

These sensors send the data to gateways placed strategically throughout the site.

The gateways then collect the data and transmit it to a central processing hub which processes and stores the information.

This data is sent to a cloud-based platform, where it is analyzed and displayed on a real-time dashboard.

Managers can access this IoT monitoring dashboard to track production status, equipment health, energy consumption, and worker productivity from any location.

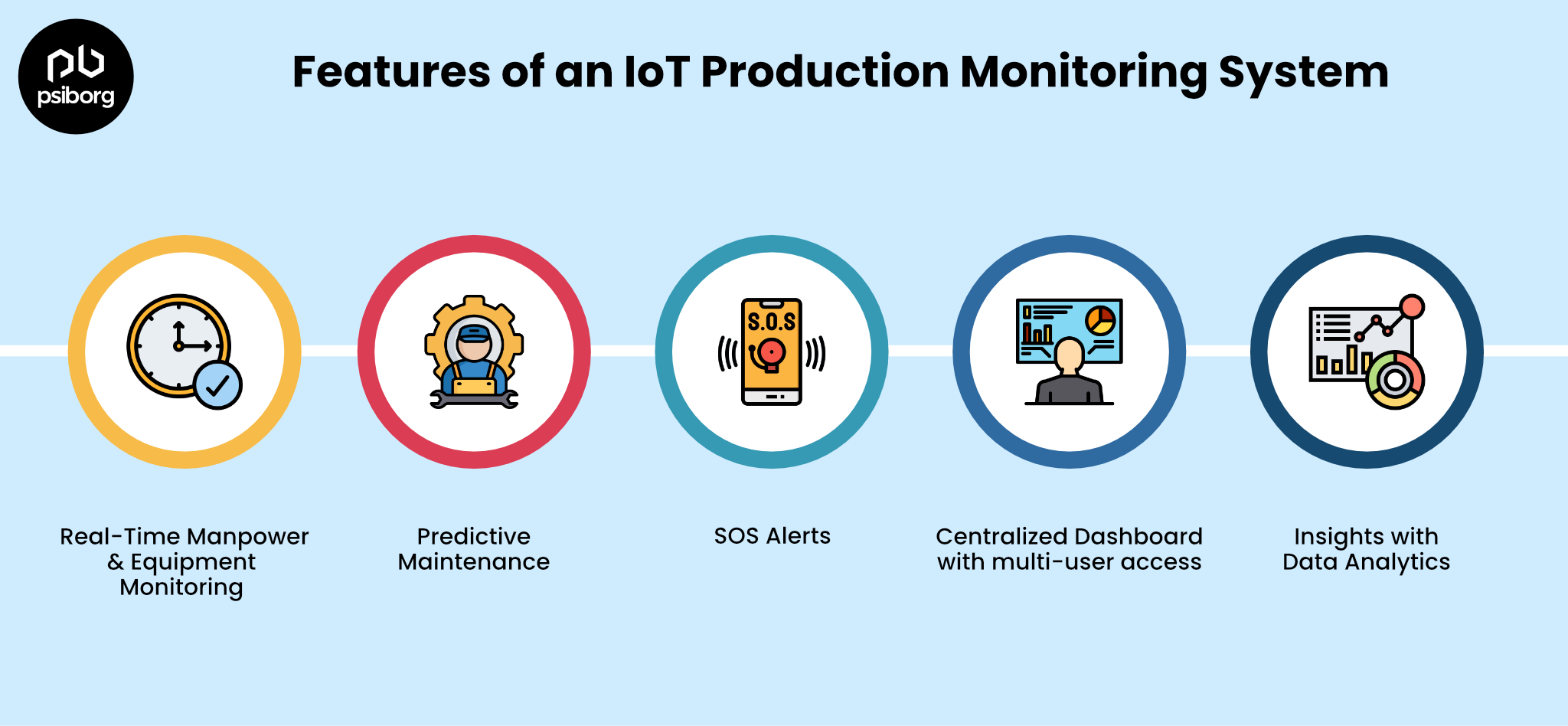

Features of an IoT Production Monitoring System

Our Production Line Monitoring System offers several key features that are designed to optimize manufacturing operations and improve efficiency are defined below:

1. Keep Everything on Track with Real-Time Monitoring

Real-time monitoring makes it much easier to keep your production process on track by allowing you to monitor equipment, workers activities. With this feature, you can monitor the performance of equipment and workers.

This level of monitoring ensures that production keeps moving forward smoothly and on schedule.

2. Improved Operational Efficiency with Predictive Maintenance

Predictive maintenance is another key feature of our system that helps in minimizing downtime. The IoT production line monitoring system monitors past maintenance activities and uses this data to predict equipment health and schedule upcoming maintenance, minimizing unexpected breakdowns. This proactive approach ensures that equipment remains in optimal condition, reducing costly repairs and maximizing production uptime.

For example, if a motor is showing signs of wear and tear, the system can schedule maintenance ahead of time which ensures the equipment is repaired before it breaks down. This prevents unexpected stoppages and boosts overall production efficiency.

3. Instant SOS Alerts for Emergencies

The system provides the SoS Alerts feature which helps by sending immediate notifications during emergencies which ensures that the right people can respond quickly. This quick response helps to maintain safety and avoid further issues on the factory floor.

For example, if a worker gets injured or if there’s an equipment malfunction, the system automatically sends out an emergency signal.

4. Centralized Dashboard with multi user access

All the data collected from machines and workers is available in a centralized dashboard. This makes it easier for managers to monitor the entire production process in one place.

The dashboard is user-friendly and displays key metrics such as production rates, machine performance, and employee activity.

5. Insights with Data Analytics

The IoT production monitoring system not only gathers data but also helps you to make better decisions. By analyzing real-time data, the system identifies trends and patterns to uncover areas for improvement. This helps you to run operations more efficiently and effectively.

For example, it can highlight which machines are underperforming, which production lines are most efficient, or where delays are occurring. With these insights, managers can make data-driven decisions to streamline processes, reduce waste, and improve overall productivity.

Benefits of a Production Monitoring System

The IoT Production Monitoring System offers a range of benefits that make maintenance smarter, and improve operations are explained below:

Workforce Efficiency

Efficient workforce management is crucial for improving productivity in the production process. The system can track worker performance, attendance, and task completion which help managers to identify inefficiencies and ensure tasks are completed on schedule.

This leads to proper use of resources and smoother workflow which ultimately boost overall productivity. Additionally, by optimizing workforce allocation, the system can help to reduce the need for excess manpower, leading to cost savings and more efficient operations.

Reduce Energy Consumption

In many production environments, energy usage is one of the largest operational expenses. An IoT Production Monitoring system can track energy consumption, helping you to pinpoint areas where energy is being wasted or inefficiently used.

For instance, if a machine is consuming more energy than usual, the system can send an alert for maintenance, preventing unnecessary costs and improving sustainability. Over time, this feature can contribute to significant savings on energy bills.

Improved Quality

One of the key advantages of using an IoT-based production monitoring system is to improve product quality. By tracking every step of the production process from raw materials to finished goods.

The system helps to ensure that any deviations from quality standards are identified and corrected quickly.

Minimize Downtime and Boost Production Uptime

Downtime can be one of the most costly issues in a production environment. The system plays a key role in reducing unexpected downtime by providing real-time data on machine health and performance.

Increased Equipment Lifespan

Maintaining equipment longevity is another key benefit of using a production monitoring system. By continuously monitoring the performance of equipment, the system can identify early signs of wear and tear which enables timely maintenance. This proactive approach helps to extend the lifespan of machinery.

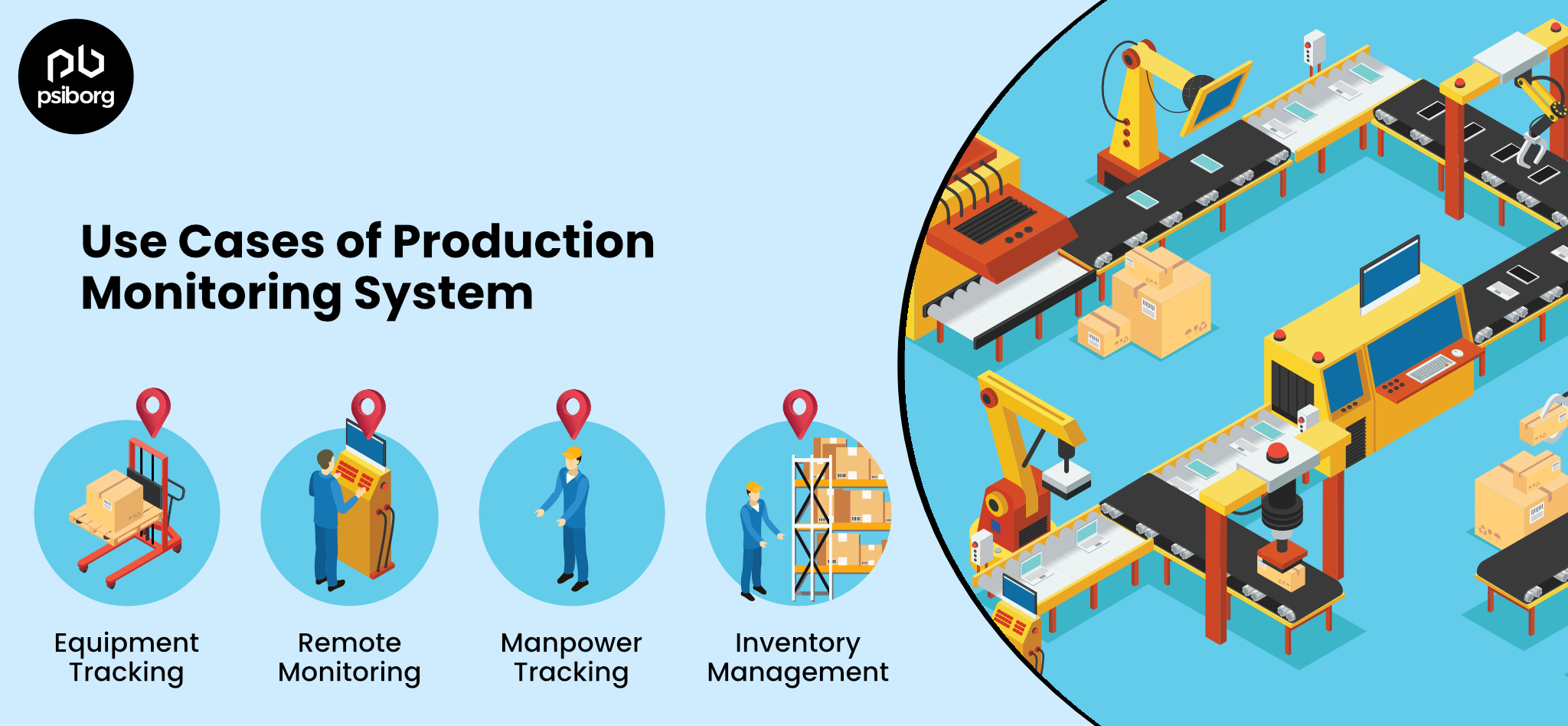

Use Cases of Production Monitoring System

The Production Monitoring software is used in various areas of the production line according to requirements. Let’s explore some real-life use cases as explained below:

1. Equipment Tracking

- The system helps to track equipment location, how much it’s being used, and its movement across the production floor.

- Additionally, it tracks who is using the equipment, when it’s idle, and how many hours it’s been in use.

- This allows for better optimization of equipment usage and helps to schedule maintenance when needed.

2. Inventory Management

- With an IoT production management system, the inventory levels are tracked automatically using IoT-enabled sensors and software.

- It ensures that materials are always stocked appropriately without over-ordering or running out.

- It reduces waste, optimizes storage space, and prevents production delays due to missing inventory.

Suggested Reading: IoT in Inventory Management and Tracking

3. Remote Monitoring and Control

- Production Monitoring Systems enable remote access to factory operations through dashboards.

- Managers can oversee production lines, analyze performance data, and adjust parameters without being physically present on-site.

- The system is particularly useful for facilities operating across multiple locations or during off-peak hours.

4. Manpower Tracking

- The system ensures that workers are effectively deployed and their productivity is maximized.

- It also tracks worker activities, movements, and attendance in real-time.

- Additionally, it enhances workers safety by ensuring compliance with safety protocols, generating alerts for emergencies and optimizing workforce management.

5. Production Planning

- The system helps managers to efficiently schedule tasks, allocate resources, and predict material needs.

- Using real-time data, the system monitors machine status, labor availability, and inventory levels which make it easier to create accurate schedules.

- Overall, the system allows managers to adjust production plans based on real-time data and make informed decisions to keep operations running smoothly.

Conclusion

Overall, the IoT Production Monitoring System provides a modern approach to optimizing manufacturing operations. By offering real-time insights into equipment performance, workforce efficiency, and production status, it helps businesses to reduce downtime, enhance product quality, and improve safety compliance.

At PsiBorg, we have developed customized Production Monitoring System using IoT that enhances your operations and boost overall productivity. Let’s collaborate to bring innovative solutions to life and drive efficiency in your industry.

FAQs

IoT (Internet of Things) in production uses interconnected devices, sensors, gateways, and equipment to gather and share data which improves manufacturing processes and operations more efficiently and effectively.

IoT provides real-time data on machinery, workers, and environmental factors that help managers to make informed decisions, prevent downtime, and optimize operations.

IoT systems can monitor data such as equipment health, machine uptime/downtime, energy consumption, worker productivity, environmental conditions (temperature, humidity) and production.

IoT production monitoring systems offer benefits like higher operational efficiency, predictive maintenance, improved product quality, and energy optimization, leading to cost savings.