Imagine losing up to 20% of your harvested grain simply because moisture went unchecked during storage, sounds alarming, right? According to the UN, nearly one-fifth of all stored grain is lost globally due to spoilage caused by improper moisture control.This issue causes huge financial setbacks for grain storage businesses and farmers, but remote grain moisture monitoring offers a powerful solution. It lets you keep an eye on moisture levels in real time, without needing to physically check storage sites.

By using sensors and IoT technology, you can quickly detect any moisture changes and act before spoilage happens.

In this blog, you’ll learn how these smart systems work, what benefits they bring, and practical steps to set up remote monitoring for your grain storage. This will help you protect your stock, reduce losses, and increase profits effortlessly.

Why is it Important to Test for Moisture in Grains?

Testing moisture in grains is not just a routine step, it directly impacts your grain’s safety, value, and usability. Here’s a focused look at why it matters so much:

Prevent Spoilage and Health Risks:

Moisture levels above safe thresholds (generally above 13-14%) create perfect conditions for mold and fungi to develop. These can produce harmful toxins that spoil the grain and threaten consumer safety.

Preserve Grain Quality and Storage Life:

High moisture accelerates bacterial growth and insect infestation, deteriorating grain quality faster. Maintaining precise moisture levels extends shelf life, ensuring your grain remains nutritious and stable over time.

Protect Financial Value:

Moisture adds weight to your grain, but excess moisture means you’re paying for water, not product. Overly wet grain risks discounts during sale or additional drying charges. Over-dried grain loses actual grain weight, lowering your return.

Ensure Compliance and Market Acceptance:

Buyers demand strict moisture limits for safe trade, and shipments exceeding limits risk rejection or penalties. Regular moisture testing helps you stay compliant, avoid costly delays, and build buyer trust.

Smooth Processing Operations:

Grains with unbalanced moisture can cause equipment blockages and processing inefficiencies on mills or food production lines. Consistent moisture testing prevents these issues, ensuring smooth and cost-effective processing.

Understanding why testing moisture is crucial naturally leads us to consider how this important measurement has traditionally been done, and what limitations those methods bring.

Challenges of Traditional Grain Moisture Measurement

Traditional grain moisture measurement techniques have served the agricultural industry for decades, but they pose several specific challenges that affect accuracy, efficiency, and scalability.

1. Sampling Limitations

- Non-representative samples: Grain moisture varies within storage, yet traditional manual sampling may miss hot spots or uneven moisture distribution.

- Time-consuming process: Collecting samples from different parts of large silos is labor-intensive and prone to human error.

2. Measurement Accuracy and Consistency

- Destructive testing (Oven drying): This reliable method requires hours to complete and destroys the sample.

- Handheld meters variability: Different meter types (capacitance, resistance) vary in accuracy and require frequent calibration; environmental factors affect readings.

3. Lack of Real-Time Monitoring

- Traditional methods provide only snapshots of moisture content, missing changes that occur between tests.

- Delayed detection of moisture spikes can lead to spoilage and loss before corrective action is taken.

4. Limited Scalability and Safety Concerns

- Manual sampling and measurement are difficult to scale in large or multiple storage facilities.

- Physical inspections increase safety risks due to hazardous environments like grain dust, confined spaces, and elevated heights.

With a clear understanding of the limits of traditional testing, it’s time to focus on a key instrument that makes grain moisture measurement practical and fast, the grain moisture meter.

What is a Grain Moisture Meter?

A grain moisture meter is a smart IoT device that is equipped with wireless sensors designed to continuously monitor the moisture content of grains in real time. Unlike traditional meters, this system integrates with cloud platforms, allowing remote access to precise moisture data anytime and anywhere.

Gain moisture meter can be of two types:

- Pin Meters: Use metal probes inserted into grain to measure electrical resistance in specific spots. Ideal for precise local readings.

- Pinless Meters: Use electromagnetic sensors applied to grain surfaces to measure moisture without puncturing the grain, offering fast and nondestructive testing.

This smart IoT grain moisture meter transforms moisture monitoring from periodic, manual checks into automated systems that significantly reduces spoilage risks and operational costs while maximizing storage efficiency.

Let’s explore how these remote systems deliver continuous and precise moisture data without manual intervention.

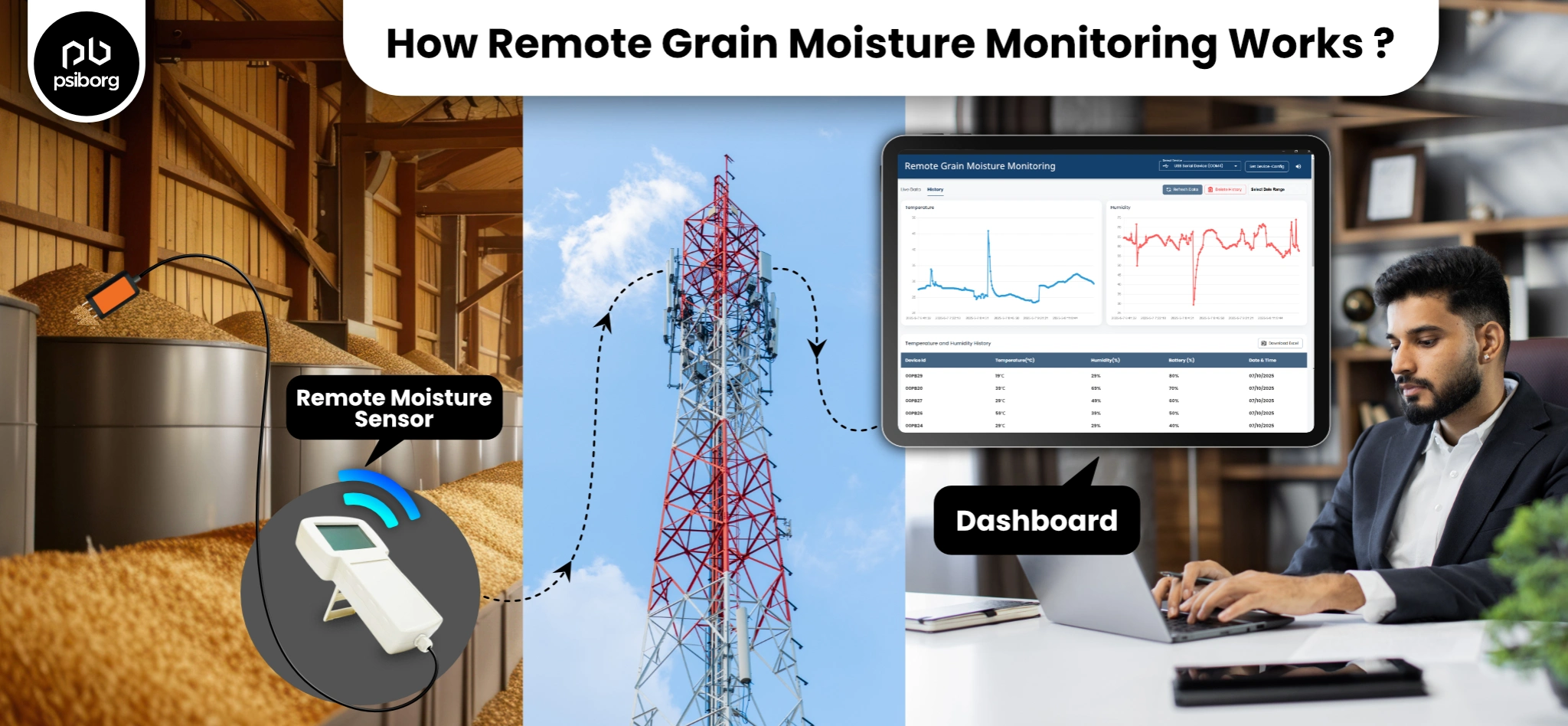

How Does a Remote Grain Moisture Meter Work?

A remote grain moisture meter uses wireless sensors installed directly in grain storage areas to constantly track moisture levels and send this information to a centralized monitoring system.

The process of remote grain moisture measurement involves multiple precise stages designed to accurately track moisture levels from inside grain storage and transmit data securely for real-time monitoring:

Installation of Sensors in Grain Storage:

Multiple moisture sensors are embedded strategically within grain bins or silos to capture representative moisture levels across different zones.

Each sensor is calibrated specifically for the grain type it will monitor, ensuring measurement accuracy under varying grain properties.

Continuous Moisture Data Collection:

Sensors detect moisture by measuring electrical properties unique to water content (e.g., dielectric constant).

Readings are taken at programmed intervals (e.g., every 15 minutes) to capture fluctuations in moisture throughout the storage period.

Wireless Data Transmission:

Collected data is transmitted wirelessly via low-power, long-range protocols such as LoRaWAN or NB-IoT.

Gateways installed onsite receive and forward this data to cloud servers, ensuring strong connectivity even in remote or large facilities.

Data Aggregation and Processing:

Cloud-based platforms aggregate incoming sensor data into centralized databases.

Proprietary algorithms process raw moisture readings, applying temperature correction and compensating for environmental factors to enhance precision.

Real-Time Monitoring and Alerts:

Users access up-to-date moisture information through intuitive dashboards or mobile apps.

Automated alert systems trigger notifications instantly when moisture levels cross critical thresholds, enabling timely drying or ventilation interventions.

Data Logging and Analytics:

Continuous data logging allows trend analysis and predictive insights. This comprehensive history aids operators in optimizing grain management practices and preventing future losses.

Let’s now examine the sensor technologies that make precise moisture measurement possible even in challenging storage environments.

Types of Sensors Used in Grain Moisture Monitoring

Modern grain moisture monitoring relies on specific sensor technologies designed to provide accurate, real-time data under varying conditions. These sensors translate physical grain properties related to moisture into electrical signals for measurement.

1. Capacitance Sensors

- Measure changes in the dielectric constant of grain caused by moisture.

- Provide fast, non-destructive readings.

- Suitable for continuous monitoring in bulk grain storage.

- Highly sensitive to moisture content variations but require calibration for different grain types.

2. Resistance (Electrical Conductivity) Sensors

- Detects changes in electrical resistance between two metal probes inserted into the grain.

- Work well for spot measurements but can be affected by grain temperature and impurities.

- Require physical contact with grain, potentially causing wear on probes.

3. Time Domain Reflectometry (TDR) Sensors

- Send electromagnetic pulses through grain and measure the reflected signal to determine moisture.

- Highly accurate and less influenced by temperature or grain composition.

- Used mostly in advanced wireless IoT systems for continuous remote monitoring.

4. Microwave and Radio Frequency (RF) Sensors

- Measure the absorption or reflection of high-frequency electromagnetic waves by the grain.

- Useful for non-invasive moisture detection with good penetration depth.

- Complexity and cost can limit widespread adoption.

Also Read: IoT-Based Temperature and Humidity Monitoring in Ships

After exploring the key sensor types that make modern grain moisture monitoring precise and effective, you might wonder how to put this knowledge into practical use to test moisture levels accurately.

How Can I Test the Moisture Levels of My Grain?

Testing grain moisture effectively requires selecting the right method based on your operation’s scale, available equipment, and the need for accuracy.

Here’s a detailed approach to ensure precise moisture measurement:

1. Handheld Moisture Meters

- Use pin or pinless meters calibrated for your specific grain type.

- Insert probes or contact the meter surface with grain samples.

- Multiple readings are recommended due to moisture variability.

2. Wireless IoT Sensor Systems

- Install sensors in storage environments for continuous, real-time measurements.

- Sensors collect data at intervals and transmit to cloud platforms.

- Ideal for large-scale operations requiring early detection of moisture spikes.

3. Calibration and Maintenance

- Regularly calibrate meters against oven drying results to maintain accuracy.

- Clean probes and sensors frequently to avoid incorrect readings.

4. Interpreting Results and Taking Action

- Compare moisture readings to recommended safe storage levels (usually below 13-14%).

- Initiate drying or aeration if levels exceed thresholds to prevent spoilage.

Also Read: Warehouse Temperature and Humidity Monitoring for Optimal Storage Conditions

Having explored effective grain moisture testing methods, a common question arises about the adequacy of traditional digital meters in large-scale warehouse settings.

Is a Digital Grain Moisture Meter Enough for Warehouse Monitoring?

Digital grain moisture meters are valuable tools for spot-checking moisture levels in grain samples, providing quick and portable measurements. However, when it comes to continuous, large-scale monitoring in warehouses, relying solely on handheld digital meters presents significant limitations:

- Intermittent Data: Digital meters provide only snapshots at the time of sampling, missing fluctuations between checks.

- Labor Intensive: Manual sampling across multiple storage points is time-consuming and may not adequately capture uneven moisture distributions.

- Limited Safety: Physical inspections in grain dust environments pose safety risks and operational challenges.

- Lack of Real-Time Alerts: Without continuous monitoring, moisture spikes or environmental anomalies might go unnoticed until damage occurs.

In contrast, IoT-based remote monitoring systems use wireless sensors deployed throughout warehouses to collect moisture, temperature, and humidity data continuously. This enables:

- Real-time remote access to comprehensive environmental data via dashboards or mobile apps.

- Automated, immediate alerts when conditions exceed safe thresholds, allowing prompt corrective actions.

- Data analytics for trend identification and predictive maintenance, enhancing overall storage management.

With a clear understanding of the advantages of IoT-based systems over traditional monitoring, it’s important to see how PsiBorg’s custom IoT development services transform grain moisture monitoring in warehouses.

How PsiBorg’s IoT Solutions Revolutionize Grain Moisture Monitoring in Warehouses

PsiBorg offers custom designed IoT solutions to provide continuous, precise, and remote monitoring of grain moisture within warehouses. This proactive system helps you maintain ideal storage conditions, reduce spoilage, and optimize operations.

Rather than offering ready-made grain moisture monitoring products, PsiBorg provides comprehensive services that include embedded hardware design, embedded firmware development, sensor integration, cloud connectivity, mobile and web app development, and real-time dashboard creation.

Our expertise lies in crafting bespoke IoT ecosystems that enable clients to monitor, control, and analyze environmental parameters crucial to their operations, such as moisture, temperature, and humidity, through smart, connected devices.

By partnering with PsiBorg, companies can use their deep technical knowledge to build precise, scalable, and secure IoT systems that fit their unique warehouse or storage requirements.

If your organization is looking for a trusted IoT partner to develop smart, integrated monitoring systems that include grain moisture along with other environmental controls, PsiBorg’s end-to-end product development and consulting services provide the foundation to unlock smart warehouse capabilities.

Contact us today to discuss how their custom IoT solutions can be designed and implemented to suit your specific business needs.

FAQs

Sensors such as capacitance sensors, resistance sensors, TDR (Time Domain Reflectometry) sensors, and microwave sensors are commonly used for grain moisture monitoring. These sensors measure electrical properties or electromagnetic responses to accurately determine moisture content.

Remote monitoring provides real-time, continuous data, enabling early detection of moisture spikes, reducing spoilage, and enhancing storage safety. It eliminates manual checks, improves operational efficiency, and allows for proactive decision-making from anywhere.

Yes, IoT enhances moisture monitoring by deploying wireless sensors that transmit data automatically to cloud platforms, offering remote access, alerts, and data analytics. This leads to more precise, timely, and efficient management of storage conditions.

A digital moisture meter is useful for spot checks but is not sufficient for large warehouses. It cannot provide continuous data or early warnings; IoT-based systems are more effective for comprehensive, real-time monitoring.

Remote monitoring uses wireless sensors placed in storage to continuously measure moisture, temperature, and humidity, transmitting data via IoT networks to cloud servers. Managers access this data remotely for real-time insights and alerts, enabling proactive management.