M2M Communication and Connected Devices

- Home

- M2M Communication and Connected Devices

M2M/IoT Connectivity for IIoT Solutions

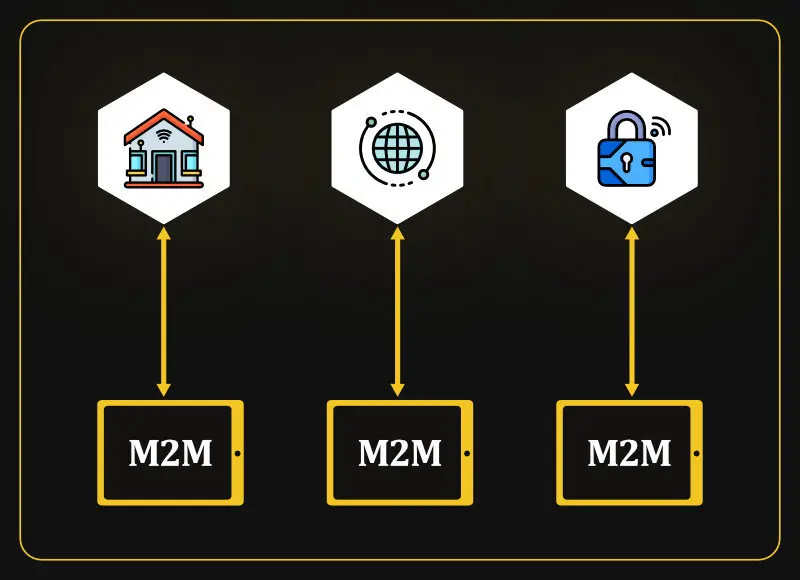

Machine-to-machine (M2M) communication occurs when multiple machines interact with each other without the involvement of humans. M2M is a popular communication technology needed for IoT communication, and its main purpose is to connect devices to the cloud. Clients, on the other hand, are often unsure of which connectivity technology is appropriate for their IoT product; this is where an IoT service provider like PsiBorg can help. PsiBorg focuses on selecting the best IoT connectivity based on the project’s requirements. Let us handle the connectivity and management of your IoT product so you can focus solely on increasing your company’s sales.

Exploring Machine To Machine Technology

Machine to machine (M2M) is a comprehensive concept that can be used to describe any technology that allows networked devices to exchange information and inform actions automatically without human interference. M2M communication devices system is standalone network equipment that uses point-to-point communication between machines, sensors and hardware. Today, M2M is among the fastest-growing technologies because it can connect millions of devices within a single network.

Working of M2M

M2M technology’s purpose is to collect the data from sensors and transmit them to the cloud. It uses a mobile network for transmission purposes, which makes it a cost-effective technology. The working of M2M is that the data is collected from the device sensors, sent to the cloud via mobile towers.

Communication Between Machine To Machine Connected Devices

The interaction between systems is carried out by artificial intelligence and machine learning, enabling them to make their autonomous decisions. It includes a wireless network in the industrial IoT, and since it is wireless, more applications can be connected. M2M virtually enables any sensor to communicate, and the systems monitor themselves and automatically respond. Any two or more machines wired or wirelessly can communicate with one another. The data is stored and translated to help in automatic actions. A vending machine can alert the distributor’s network when a particular item runs out of stock and sends a refill. M2M communication devices are vital in supply chain management and warehouse management systems.

Benefits of M2M technology

M2M technology comes with numerous benefits; some of them are: M2M technology is cost-effective and easy to maintain. The equipment maintenance is secure, which means the chances of downtime are meager Increases the business process. Customer service has improved. Proactive monitoring of devices.

Applications Of M2M Technology

M2M technology is designed with the purpose of monitoring devices remotely. Some of the applications where M2M technology is used are:

- M2M technology in vending machines can be suitable for sending information whenever there is a shortage of items.

- Inventory Tracking systems are one of the best examples where M2M technology is applied

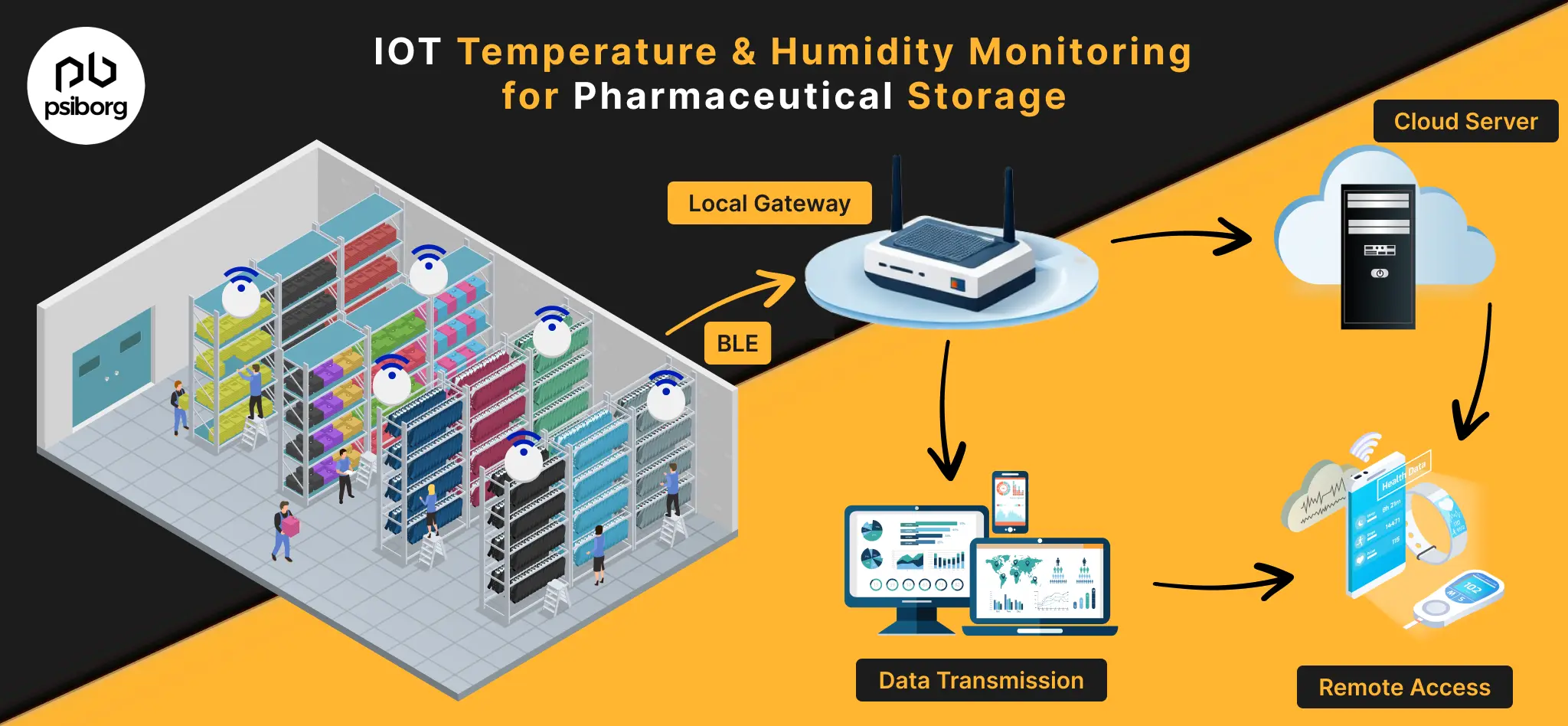

- In industries, M2M technology is used for detecting factors affecting operations on work sites like temperature, equipment etc.

- In the medical sector, technology is used to monitor patients’ health in real-time.

- Digital payment gateways use M2M technology.

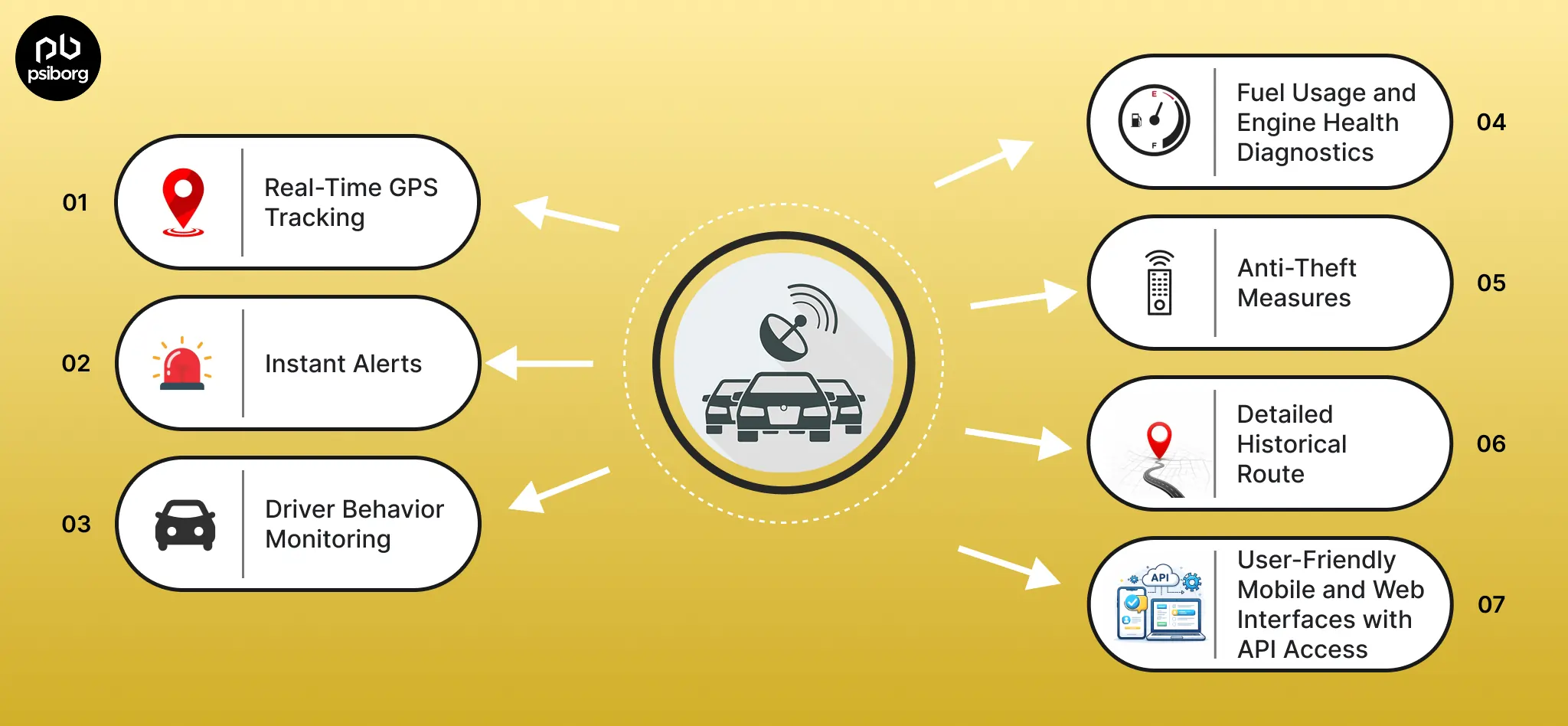

- M2M technology is also used in the field of robotics, traffic control, fleet management, etc.

Interested? Let’s Get Started

STEP 1

Contact Us

Reach out to us via the contact form or give us a call to initiate the conversation about your IoT development needs.

STEP 2

Get Consultation

Schedule a consultation with our experts to discuss your project in detail, aligning our approach with your unique vision.

STEP 3

Get a Cost Estimate

Receive a detailed cost estimate tailored to your project’s scope and requirements, ensuring transparency in your investment.

STEP 4

Project Kickoff

Once finalized, we'll initiate the project kickoff, marking the beginning of our collaborative journey toward successful IoT product development.

Why Choose PsiBorg?

Ready to elevate your IoT devices with advanced hardware design solutions? Contact us today to discuss your project requirements and explore the possibilities.

Industry-Leading IoT Expertise

With almost a decade of rich experience in IoT technology, we provide tailored services to various industries. Our team strives to deliver innovative and effective solutions that guarantee brilliant connectivity and automation.

End-to-End IoT Solutions – From Concept to Deployment

From the initial idea to launching your IoT project and providing continuous support, we take care of it all. You can completely focus on your business while we ensure a hassle-free experience for our clients.

Secure and Scalable Architecture

We guarantee you scalable, reliable and future-proof solutions. They are designed to provide operational efficiency, strong security, reduce downtime and align with your evolving needs.

Customized IoT Solutions for Diverse Industries

Trust us to offer tailored IoT applications that perfectly align with your specific industry requirements and deliver smart, efficient, and cost-effective solutions.

Our Process

1

Planning

PsiBorg starts any IoT development phase with planning. Firstly, the team experts strategically outline the scope and objectives of the solution and accordingly decide on resource allocation. The planning phase is the foundation of successful IoT solution development.

2

Analysis

After planning comes the requirement analysis stage, where the main objective is understanding the end user's needs and requirements. Our tech team gathers detailed insights to decide the flow of the development.

3

Design

In the design phase, a detailed blueprint of the project is created to clearly define the system’s architecture, data structure, and interfaces. In IoT solution development, the designing phase is also accompanied by prototyping, to validate the expected outcomes.

4

Implementation

In the implementation stage, the actual concept and product prototyping take place. The PsiBorg team, at this stage, initiates the MVP for the IoT solution. The implementation stage includes the development of all the hardware, firmware, and software. After implementation, the system undergoes integration and testing.

5

Testing & Integration

The testing stage is part of the development process because testing of the final product is necessary. Our team checks and thoroughly tests everything- hardware, firmware, and software. After conducting unit testing and validating the system, we deploy the project for production.

6

Maintenance

The final stage involves maintenance and support of the deployed solution. In the maintenance phase, PsiBorg offers to address waves, do updates, and provide ongoing assistance to the users.

Got problem worth solving or some amazing idea? Share with us!

Once you let us know your requirement, our technical expert will schedule a call and discuss your idea in detail post sign of an NDA.

All information will be kept confidential.

Speak with an expert

- Get help evaluating if PsiBorg is right partner for you

- Get information on IoT Solution and pricing

- Get a demo of how IoT can help with your use case

IoT Development Solutions for Every Industry

As one of the IoT product development companies, we deliver IoT products that are designed for performance, security, and longevity.

Automotive Industry: Manpower and Asset Tracking

For monitoring workforce productivity and efficiently managing valuable assets in the automotive sector, we build reliable IoT-based tracking solutions.

Mining Industry: Deployed Temperature and Humidity Monitoring

Our highly efficient IoT solutions help mining companies learn about the environmental conditions, ensure safety and comply with industry regulations.

Defence: Deployed Shipment Tracking Solution

To provide security and reliability in the defense sector, we provide real-time tracking solutions that help closely monitor the movement of all critical shipments.

Research and Development Sector: Cattle Health Monitoring System

Researchers and farmers can track cattle health, improve productivity and detect diseases early with our IoT-enabled livestock monitoring systems.

Consumer Electronics: SoS and Emergency Devices

Our IoT app development company provides efficient SoS and emergency devices that help in monitoring emergencies in real time and ensure quick responses and better safety.

Case Studies

The true success of a business lies in the trust and partnership cultivated between clients and the company. Click to read about some of our proudest achievements.

Frequently Asked Question

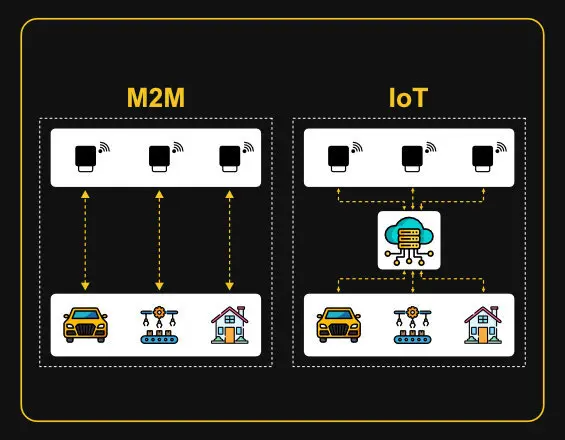

- M2M makes use of point-to-point communication between sensors, hardware and more over wired or wireless network whereas IoT systems rely on internet protocol (IP) address to send data collected to cloud or gateways.

- M2M Communication impacts businesses whereas IoT impacts users. IoT transforms enterprises meanwhile M2M impacts management applications.Difference between IoT and M2M

Machine-to-machine communication makes the Internet of Things possible. From PLC to Vending machines to medical equipment to various low power Wide area sensor networks, there are many applications.

Both M2M and WSNS are networks that allow devices to communicate with each other over wireless channels. Both are subsets of IoT. WSN is an application of m2m communication.

IoT includes a technology stack and m2m is one of the subsets of IoT. So basically, m2m communication is data transfer between two devices without human intervention, for example if a smoke sensor is sending an alert to a gateway, then there is m2m communication between sensor unit and gateway.