From our houses to our work, IoT is making everything simpler. There’s no doubt about the popularity of the Internet of Things, and now IoT has spread its wings in inventory management.

IoT inventory tracking has a very prominent impact on supply chain management. Inventory management systems using IoT will not only scale down costs and time but will also provide a way to manage inventory in any warehouse or supply chain effectively.

Since IoT is transforming supply chain management and logistics, let’s understand how IoT makes inventory management a cakewalk.

What is the Internet of Things?

The Internet of Things describes physical objects that are embedded with sensors, processing abilities, software, and other technologies and that connect and exchange data with other devices and systems over the Internet or other communication networks.

How is IoT Used In Inventory Management?

An IoT inventory management system refers to a connected system that is used to manage the flow of goods and materials in a warehouse or an organization.

The term inventory management includes everything from raw material ordering and storage to the track of the material till the production ends . It is also about maintaining optimal inventory levels, reducing overstocks and under stocks, and improving the timely delivery of customer orders.

With huge inventories in large warehouses, there is a risk of things going unnoticed by the human eye, but that’s not the case with IoT technology.

Smart IoT based Inventory system uses beacons, gateways, and advanced analytics to improve equipment tracking in warehouses, manufacturing, construction, healthcare, oil and gas, mining, and electrical industries.

Also Read: IoT in Manufacturing Industry

Technology Behind IoT-Based Inventory Management

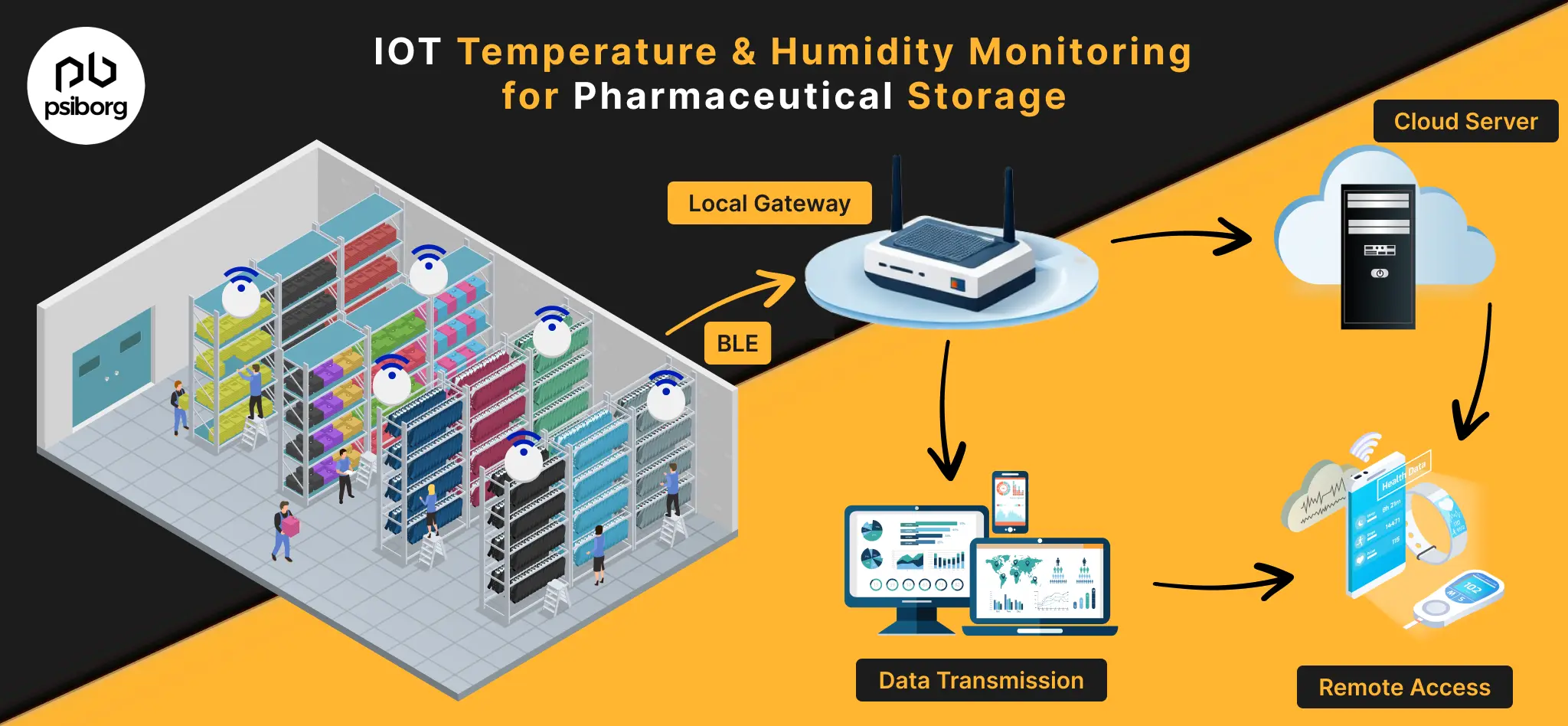

Several technologies are utilized to develop an equipment tracking system, such as LoRa, GPS, BLE, and other wireless technologies. BLE and UWB both have common attributes and are considered best for indoor position tracking. Moreover, UWB is far superior to Bluetooth, because UWB determines location via ToF and Bluetooth determines location via RSSI.

However, in this article, we will discuss the BLE-based inventory tracking system that is a widely used technology in indoor settings.

BLE based inventory management and tracking system consists of BLE tags and BLE receiver. Each BLE tag includes a Unique Identification Number (UID) that is associated with the inventory item, .i.e BLE tag UID is associated with the product model, batch number, and so on. These BLE tags comes in different form factor and can be sticked on manufacturing material.

These BLE tags broadcasts BLE signals which are received by the strategically placed BLE gateways/Receivers. These receivers , based on the received RSSI and UID provides the location of material/ equipment in the premises. The gateways collects this data and send it to the server where complex algorithms are run on this data and various insights are produced for the Admin.

In this way, IoT and BLE technology allow monitoring of inventory using a smartphone or laptop remotely and in real-time.

Here’s a closer look at the technologies that make smart inventory management a reality. BLE systems consist of two main parts: BLE beacons (which we commonly call as “BLE tag”), BLE gateways and Inventory management and tracking Software.

Ble Tags or Ble Beacons

These BLE tags are pasted on the material to the tracked. Every tag has a “Unique Identifier” which is sent to the gateway along with RSSI.

Ble Gateways

BLE Gateways are strategically placed throughout the premises. These devices receives radio waves from beacons and collect information from all the BLE beacons that are within range.

Inventory Management And Tracking Software

The software processes the data, displays inventory in different zones on a map, and generates reports.

Issues With Traditional Inventory Management

Inventory management is one of the challenges in most industries. Keeping track of numbers and availability helps in improving work efficiency to a great extent. However, entering data manually can lead to discrepancies. Some of the issues are listed below.

Absence of Real-Time Inventory Data

Manually updating spreadsheets to track inventory may lead to improper inventory management.

There is always a possibility that the inventory manager might forget to update a particular product arrival and repeat orders for the same might be placed. IoT helps avoid such lapses. IoT-based Inventory management helps in tracking the products and all inventory data in real-time.

Imprecise Projection of Demand And Suppy

It has been seen that manual inventory management is unable to precisely bridge the inventory and the demand gap. Additionally, it is unable to give any demand insights for the future or streamline data to analyze the trends. It is very important to achieve IoT-based inventory optimization to avoid piling non-essential stocks and increasing inventory load.

Decentralized Control

A centralized approach to business is very essential for a successful business. IoT-based inventory management enables you to update the data on all the devices as soon as you make a sale on a point-of-sale (POS) device.

No Optimization

Manual inventory management can not be scaled up and down as per need. On the contrary, an IoT-based inventory management system helps in the integration of cost-control methods, predictive trends, and process optimization.

MISPLACED ITEMS IN INVENTORY

Manual inventory management may lead to loss of inventory which is avoidable. Using an IoT-based inventory management system, every item can be traced and tracked thereby eliminating the chances of inventory loss

The Internet of Things is rapidly changing the face of inventory management and the global supply chain. According to research done by McKinsey Global Institute, IoT can contribute immensely to potential inventory management, supply chain management, and logistics. In monetary terms, IoT’s impact on inventory management could reach anywhere between $560 billion and $850 billion per year by 2025.

How IoT Improves Inventory Management

IoT inventory tracking uses real time inventory sensors to collect and convey data on inventory items in real-time. An inventory management system using IoT is a wireless inventory tracking technology that aims to make inventory management more efficient. Below are the mentioned ways in which IoT improves inventory management.

Real-Time Communication

IoT is known to improve real-time communication in logistics and inventory management. Sensors and devices fixed to various inventory-related items help improve communication by real-time monitoring of data.

Precise, Detailed, Itemised, Location Monitoring

With IoT, one can pinpoint the location of every item in the inventory. We can track its location, know its delivery status, transit status, expected time of arrival, etc extremely accurately. All this information is available in real-time and vastly streamlines and optimises the inventory management process.

Itemised inventory tracking is carried out through warehousing and processing With IoT, the number of specific inventory items that can be tracked will increase massively.

Touchless Data Collection

The lesser human intervention the better it is for an inventory management system. With automated data collection of the inventory items, the presence in the inventory of every item can be ensured.

Warehouse Management

The use of technology-enabled by the IoT along with improvements in 5G wireless technology is proving to be helpful in improving the logistics of warehouse management.

Warehouse management is concerned with the optimization of the efficient utilisation of that space. Once the usage pattern is known, the available space in a warehouse can be better allocated.

More frequently used items can be stored more closely at the access points to improve warehouse efficiency.

IoT in inventory management enables the use of smart shelves and storage bins that can quantify the duration for which things have been held in those places and how full they are. This data can be sent to the server for analysis and actionable insights for better optimization of inventory space.

Suggested Reading: SMART IOT SOLUTION

Artificial Intelligence Algorithms

Artificial intelligence has given us the power of smart algorithms that can help us track and manage inventory many times better than what an average human can do. Careful analysis of IoT data by AI systems will help in identifying patterns that can’t be observed by a human. This process is bound to improve inventory management decision-making. Functions like replacement inventory orders can be better handled by AI-powered inventory management systems.

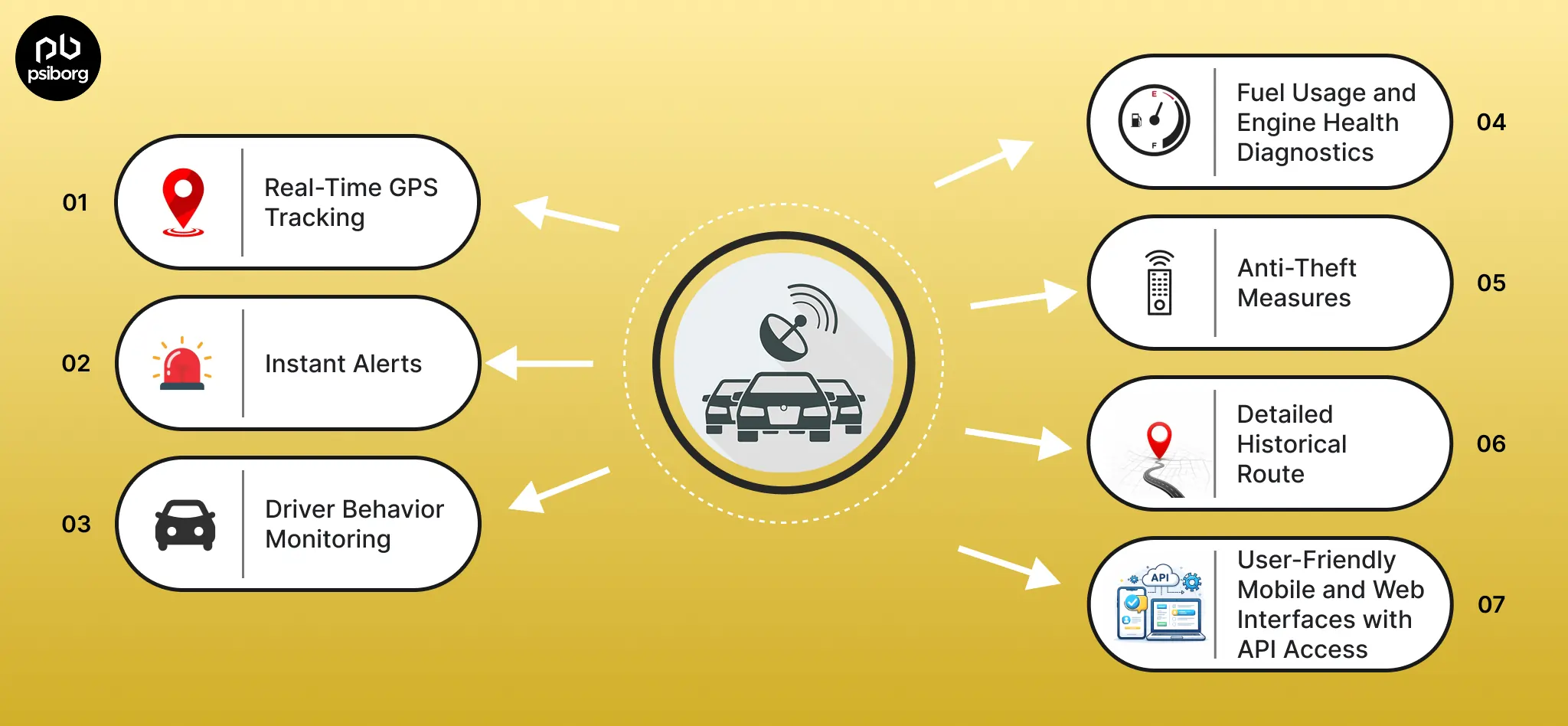

Equipment/Fleet Inventory Management

If a company’s inventory management system includes equipment and vehicle fleets, then in such a case, IoT is very useful. IoT-enabled tracking methods that use GPS locations to gather data about fleet or equipment transit status help in better management and utilisation of the tracked fleet reducing unauthorised access and optimising the process overall.

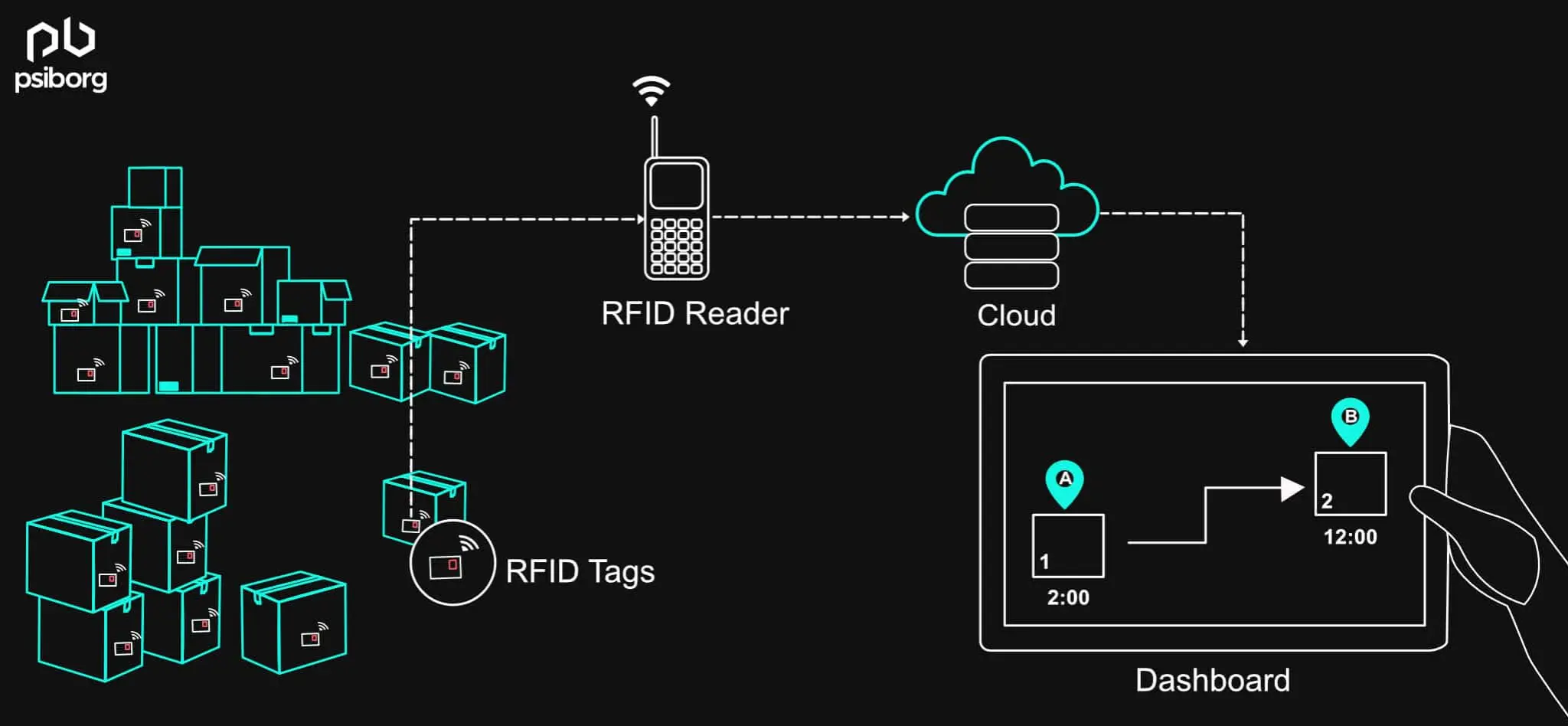

Better Management Of Lead Times

RFID inventory tracking system is crucial in determining the lead times required to assemble all the parts necessary for manufacturing. High lead times get pinpointed to avoid hurdles caused by a critical part(s) being missing and causing stoppages in the production processes. This helps in better synchronization between production processes and inventory demand fulfillment.

IoT Integration In Inventory Management

Switching to IoT for inventory management is a good decision for most companies. There are, however, some concerns that need to be taken care of before the full-fledged adoption of IoT for inventory management. These are:

- Investment cost

- Standards that help devices communicate with each other

- Security

- Scalability

Notwithstanding these issues, there has been a downward trend in the investment cost of IoT technology. Many organizations are seeing immense financial benefits arising out of IoT-based inventory management and thus are adopting IoT for efficient inventory management.

Also, Read IoT and Logistics, IoT Asset Tracking and Monitoring

PsiBorg is an IoT product development company, building end-to-end IoT solutions for different sectors ranging from the supply chain, defense, and industrial automation to security systems.

FAQ

RFID inventory tracking system includes RFID (Radio Frequency IDentification) tags and readers. It is an automation system that collects and documents data to conduct real-time product counts and offer estimations based on the said data. With RFID technology in IoT, the items can be scanned and cataloged from anywhere, even when they are hidden pellets.

Implementing IoT in inventory management is of great benefit. It automates and simplifies the burdensome and time-consuming traditional inventory tracking, where human errors frequently occur. In addition, IoT improves inventory management by offering accurate data on products and real-time alerts if they get expired or damaged.

In an BLE inventory tracking system, BLE tags are used. BLE tags attached to products can track inventory throughout the supply chain. It offers real-time data on product location, stock level, and much more.