There is a use case for IoT in every industry. However, not everyone is aware of IoT’s use. It is for this reason that blogs are in place. Through blogs, we make people aware of the different applications of IoT in all environments.

Today, let’s talk about the use of the Internet of Things (IoT) in oil and gas industry and how the use of IoT can be a game changer in the oil and gas industry for improving resource utilization.

To paint a concise picture, IoT offers a range of solutions to improve operational efficacy, improve safety, and gain more control over processes and equipment.

Let’s move ahead and discuss everything in detail.

IOT’S ROLE IN SHAPING THE FUTURE OF OIL AND GAS INDUSTRY

Oil and gas companies use IoT to implement interconnected devices, sensors, and systems. Through the Internet of Things, data is collected, communicated, and analyzed without human intervention.

Now, the question is: why does the oil and gas industry need IoT?

So, the oil and gas industry fuels the global economy and powers important sectors like transportation, energy generation, and manufacturing. But this industry also faces an equal amount of challenges, such as dealing with aged equipment, legacy systems, geopolitical issues, and hazardous environments.

Moreover, it is high time now to adopt advanced technologies like the Internet of Things (IoT) to triumph over these challenges.

Integrating IoT in oil and gas industry is literally like having eyes everywhere, which is certainly not possible by being physically present everywhere. By leveraging IoT, physical objects like sensors, software, and network connectivity are integrated into the ecosystem. These devices collect and communicate with each other in real-time thus allowing smooth task execution.

By anticipating and assessing equipment and processes at every stage before a problem arises, companies can differentiate themselves from the competition with smart oil and gas IoT solutions. Everyone will be safe, and the downtime will be minimized.

CHALLENGES FACED BY OIL AND GAS INDUSTRY

The oil and gas industry’s operations are categorized into three stages – upstream, midstream, and downstream.

In the upstream stage, the oil and gas companies search for new oil reservoirs on sea and land; the midstream stage is about dealing with logistics and supply; and the downstream stage is for marketing and distribution.

Now, each stage has its challenges that an O&G company can overcome by adopting IoT.

However, before explaining the IoT solutions and the need for IoT in the oil and gas industry, let’s discuss the challenges in all three stages in detail.

UPSTREAM STAGE

Maintaining complex, huge, and expensive machinery is the biggest challenge at this stage. Upstream stages involve exploring the earth’s surface for oil and gas extraction, which requires heavy machinery and advanced technology.

IoT can help companies better investigate and inspect the surface by integrating it in the upstream stage. Furthermore, facilities can also remotely manage risk, prevent malfunctions, track schedules, and get automatic alerts in case of damage.

MIDSTREAM STAGE

Traditionally, at the midstream level, along with transportation, physical inspection is done to ensure things comply with existing regulations and norms. However, these physical inspections are daunting and often lead to ignoring little things.

However, by utilizing IoT, organizations can remotely detect fluctuations in parameters and ensure compliance.

DOWNSTREAM STAGE

Downstream is the stage that involves treating harmful waste and retrieving oily sludge. But this is also the most difficult task for all the oil and gas industries. IoT can help organizations by enabling efficient energy usage and by transforming the entire waste treatment process.

Now since we are aware of the challenges that the oil and gas industries face, let’s look at IoT solutions that will help organizations overcome those challenges.

TOP USE CASES OF IOT IN OIL AND GAS INDUSTRY

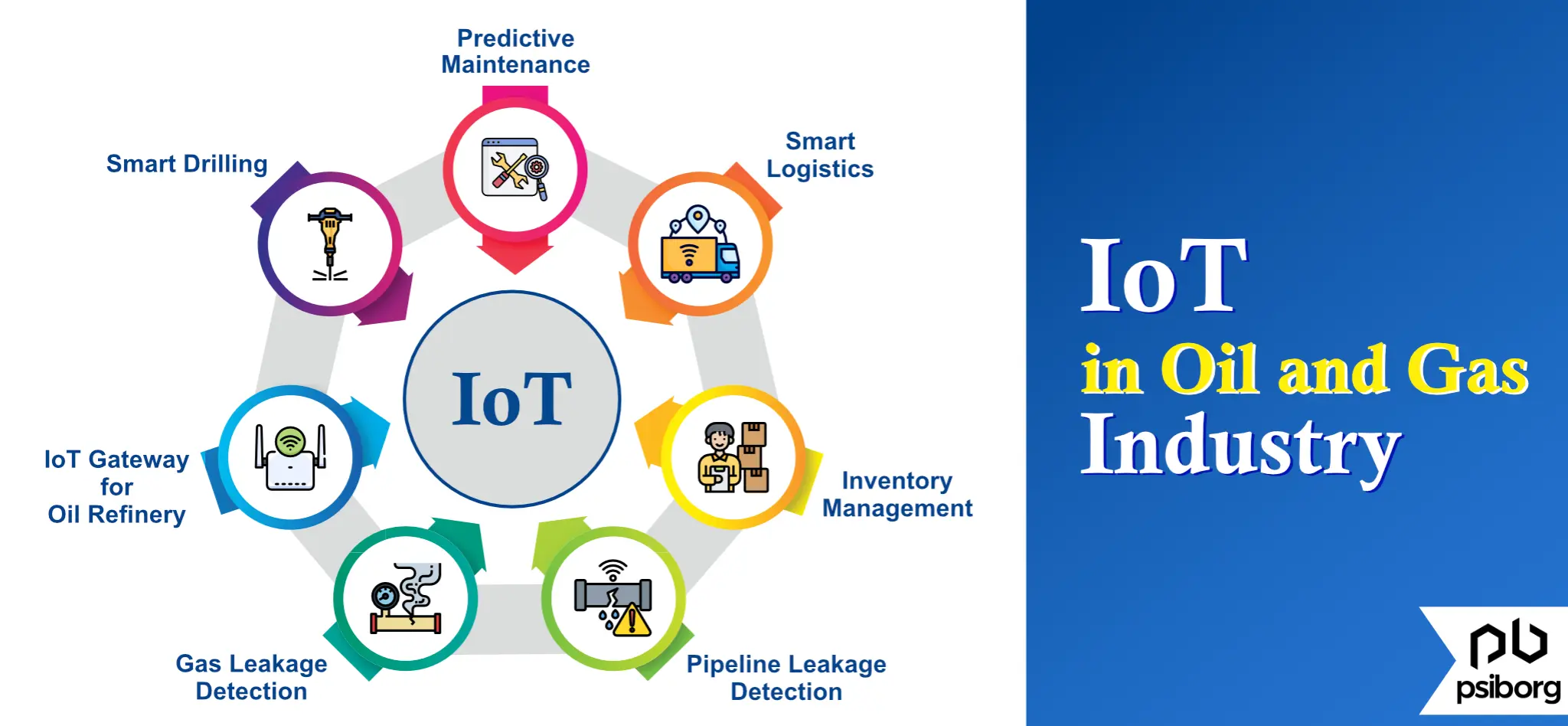

The various applications of IoT in oil and gas industry are as follows:

1. SEISMIC DATA ANALYSIS

Seismic data analysis is a very crucial process in the oil and gas industry and IoT aids this process by offering data-driven insights about the subsurface structures and the possibilities of the presence of hydrocarbon reservoirs.

The sensors collect and transmit real-time seismic data and help accelerate the exploration process. By using IoT sensors and advanced data analytics, better decisions can be made regarding the drilling and extraction process.

2. SMART DRILLING

Drilling the surface for extraction of oil and gas is a substantial part of the oil & gas industry. However, the total cost of drilling accounts for around 30% of the total cost.

Therefore, integrating IoT devices can accelerate operational effectiveness and optimize the usage of water, chemicals, and sand.

For instance, IoT devices allow the tracking of drilling parameters such as temperature, pressure, and equipment performance. This way, the team can take instant measures to adjust and enhance the drilling efficiency.

In addition to this, the data collected by the IoT will allow predictive maintenance by detecting potential equipment problems before the situation worsens, thus reducing downtime.

3. PREDICTIVE MAINTENANCE

The appropriate evaluation of assets in the O&G industry will provide accurate daily insights into the operational process and will assist managers in maintaining data for secure operations. Embedding IoT devices on industrial machinery will make it easy to predict the time of maintenance. This allows for scheduling repairs before breakdowns and improving employee safety.

With IoT-based predictive maintenance, unplanned downtime will be reduced significantly.

4. SMART LOGISTICS

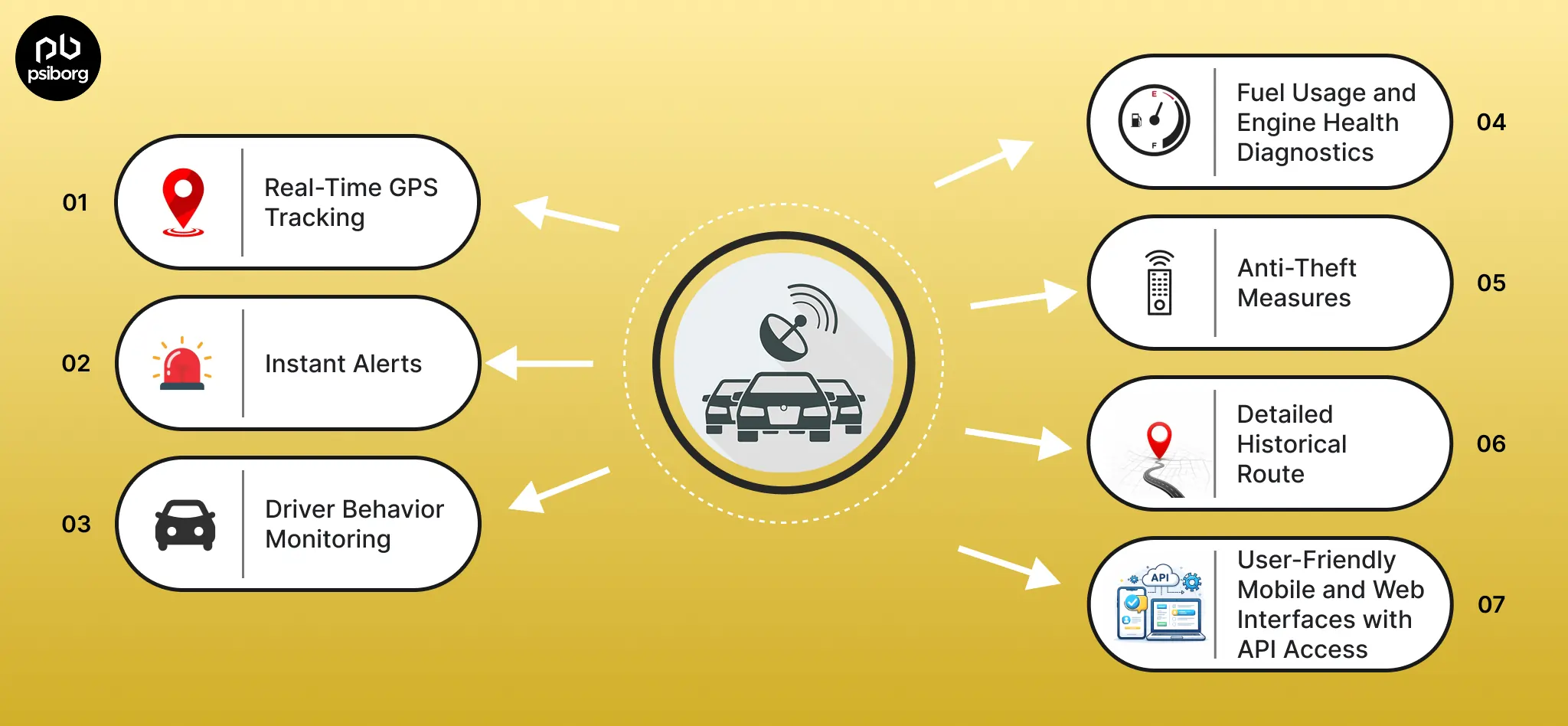

Integrating IoT in logistics will improve connectivity and multiple activities like supply chain and warehouse management.

IoT in oil and gas transportation will offer transparency in product transportation and allow tracking of vehicles for trouble-free logistic operations. Thus, with the use of Internet of Things technology, there will be transparency in tracking logistics and proactive management of materials and equipment. This will also reduce the maintenance cost.

With IoT, it is possible to remotely monitor areas that are difficult to monitor without any human intervention, such as hazardous locations.

5. INVENTORY MANAGEMENT

IoT sensors installed in the inventory area collect information related to the refinery and notify about the materials that are scarce and types of oils that have been delivered or are scheduled to be delivered.

This way, the organization can make important decisions regarding the manufacturing, inventory, and production stages. The Internet of Things with advanced connectivity offers real-time and efficient inventory management that will streamline the supply chain in the O&G industry.

6. PIPELINE LEAKAGE DETECTION

The most commonly occurring cause of leakage is corrosion in pipelines, so it is crucial to monitor pipelines. But obviously, no human can monitor huge, lengthy pipelines. To monitor pipelines remotely in real-time, you need IoT technology.

Pipeline leakage detection and pipeline health monitoring have become way more convenient and easier with the use of IoT.

With IoT technology and sensors, one can monitor gas flow, concentration, temperature, and several other parameters to predict a leak. Immediate action will be taken to prevent any leakage with the deployed alert system.

7. HARMFUL GAS LEAKAGE DETECTION

It’s crucial to keep an eye on levels of hazardous gases like methane, hydrogen sulfide, propane, and carbon monoxide. And if it’s a commercial property, it gets more crucial to avoid any poisonous gas leaks.

However, it’s very difficult to monitor these long, huge pipes. That’s why you need an IoT system equipped with sensors and devices to detect harmful gas leaks. The sensors can be placed along the pipeline route and detect the presence of harmful gases such as hydrogen sulfide, propane, and carbon monoxide and send alerts.

This sensor-equipped solution will reduce the risk of gas explosions and associated fatalities.

8. IOT GATEWAY FOR OIL REFINERY

IoT is all about collecting data in real-time without any human intervention. That’s why, in places like oil and gas refineries, where placing humans at every stage can be risky, you need an IoT system to collect and relay important data and alerts.

To collect data from assets, heavy machinery, and refinery equipment, devices such as sensors and gateways are mounted. Control of oil/gas extraction and refining processes is achieved by using data such as oil tank levels, machine parameters, energy usage, and fuel stock to manage any discrepancies.

Oil and gas refineries must be strategically located for informed decision-making and process improvement. Data is analyzed over time through gateways to achieve this.

9. REMOTE SITE MONITORING

IoT makes remote site monitoring possible. Through IoT based remote monitoring systems, the management team can receive real-time data on crucial parameters in storage facilities. The remote site monitoring system has two major applications via inventory management, and safety and security measures.

We have already discussed inventory management in the above section. However, in terms of safety and security, the IoT driven surveillance systems and smart fencing can detect unauthorized access, thereby protecting valuable assets and personnel.

ACCELERATE YOUR OIL & GAS BUSINESS WITH PSIBORG’S IOT SOLUTIONS

It’s high time to embrace IoT technology to simplify and optimize the end-to-end operations in oil and gas companies.

However, setting up an entire team can be challenging and expensive. However, PsiBorg is here to help. As an IoT solution provider, we develop industry-specific IoT solutions for companies. Our expertise in the manufacturing and IIoT sectors helps companies integrate IoT and supports the successful introduction of IoT for automation and transformation.

Imagine all the decision-makers being equipped with real-time data and having the power to identify areas for improvement.

Our IoT solutions will give your oil and gas business the edge that every business needs to become successful.

Reach out to us or simply contact us by clicking here.

FAQ

In the oil and gas industry, IoT involves connecting sensors and devices to collect real-time data from exploration, drilling, production, and transportation processes. This data is analyzed to enhance operational efficiency, monitor equipment health and optimize decision-making. IoT enables predictive maintenance, improves safety, and enhances overall productivity in the oil and gas sector.

IoT applications in the oil and gas industry include real-time monitoring of equipment, predictive maintenance, asset tracking, safety enhancements through environmental monitoring, and remote operation and control.

In the oil and gas industry, IoT technology generates vast amounts of real-time data from equipment and processes. Data analytics process and analyze this data to derive valuable insights, enabling predictive maintenance, optimizing production, and improving safety. The combination of IoT and big data analytics improves decision-making, operational efficiency, and overall performance in the oil and gas sector.