Embedded Hardware Design Services

- Home

- Embedded Hardware Design

IoT Hardware Development Services

At PsiBorg, we offer expert embedded hardware design services to build reliable, scalable, and production-ready IoT hardware solutions. Whether you’re developing a connected consumer device or a rugged industrial solution, our team specializes in embedded system hardware, Internet of Things hardware design, and custom PCB development tailored to your product’s requirements. From concept and schematic to hardware prototyping and field testing, we ensure your product is optimized for performance, power efficiency, and manufacturability.

Our Specializations in Internet of Things Hardware Design

We understand that every IoT project is unique, which is why we offer product companies a comprehensive solution to develop high-quality hardware components. Our services include:

Hardware Prototype Development & Validation

With rapid hardware prototype development , we turn concepts into testable boards fast—covering PCB fabrication, assembly, and hardware validation testing. We provide the design and development of a diverse range of IoT devices be it sensors, actuators, or any other IoT hardware.

IoT Hardware Integration and Application Deployment

We ensure your IoT hardware integrates with cloud platforms, web dashboards, and mobile applications. Our team handles data formatting, API mapping, and secure communication between the device and software layer. We make sure IoT devices work reliably in live environments, enabling real-time insights and remote control.

Our Technology Stack

IoT Data Protocols

- MQTT

- CoAP

- HTTP/HTTPS

Cloud Services

- AWS

- Azure

- Google Cloud

Back-End & Database Systems

- Node.js

- MongoDB

- InfluxDB

- MySQL

Front-End Technologies

- React.js

- React Native

Firmware Development Languages

- C

- C++

IoT Communication Protocols

- BLE

- LoRa

- UWB

- WiFi

- LTE 4G & NB-IoT

Our Approach to IoT Device Development

1

IoT Hardware Requirement Analysis

We begin by understanding the product’s intended environment, power requirements, communication protocols, and end-user expectations. Our team collaborates closely with clients to translate their use case into clear technical specifications. This foundational step ensures all downstream decisions—from sensor integration to power architecture—align with the application’s real-world demands.

2

Components Selection

Once requirements are defined, we identify the right components to balance performance, cost, and scalability. This includes microcontroller selection based on memory, I/O requirements, and power profiles, as well as selecting wireless modules, sensors, and power components. Our team ensures that all chosen parts are production-grade and available at scale, reducing risks during mass manufacturing.

3

Circuit Design

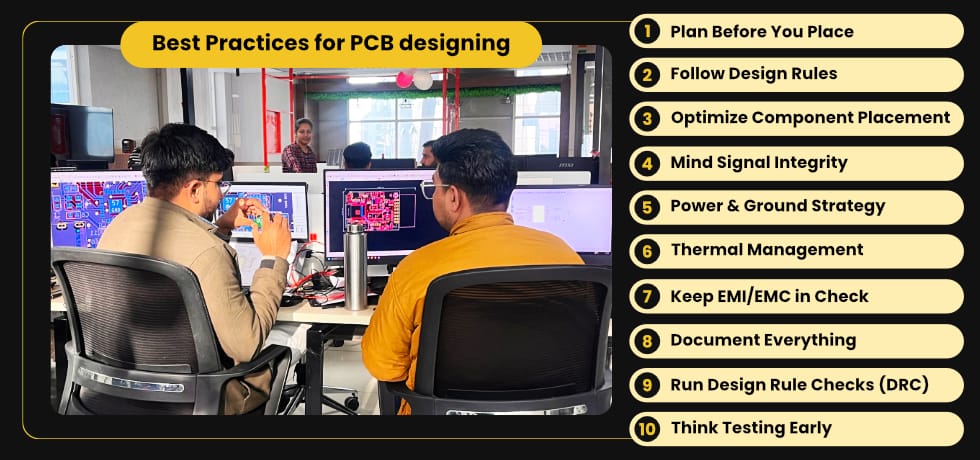

After component finalization, we create detailed schematics and PCB design layout for your custom IoT device design. Here, we follow DFM (Design for Manufacturing) principles to ensure the hardware is optimized for assembly and testing. Special attention is given to sensor integration, signal integrity, and power routing to avoid electromagnetic interference or voltage fluctuations that may affect performance.

4

Prototyping & Testing

The final step is to build a prototype of the hardware design and test its functionality in real-world conditions. Validation tests are conducted to ensure that sensors are reliably collecting data, processors are correctly executing computations, and communication modules are reliably transmitting data.Any necessary optimizations are implemented before scaling up for field deployment or production.

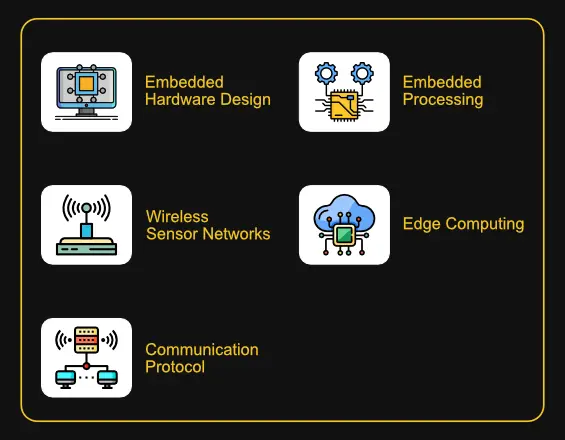

Building Customised Embedded Hardware

We build embedded systems with our experience and understanding in embedded hardware design, embedded processing, wireless sensor networks, edge computing, and different communication protocols. Our PCB designers can design multi-layer PCB boards with perfection.

Hands-on Experience on Latest Tools And Technologies

We are into rapid prototyping as we have developed modules during our journey till today. We ensure that we follow the right manufacturing process, best design principles for manufacturing, and correct material for the device. Our team also makes sure that the product is designed to withstand the environment and must comply with quality and safety standards. We have Designed Nodes, and Gateways for IoT solutions that can be customized for various Cloud Services and Analytical tools Leverage our design and development expertise for embedded Hardware Design from the initial prototype to manufacturing design. While designing a hardware, our engineers are very careful about common design mistakes in PCB.

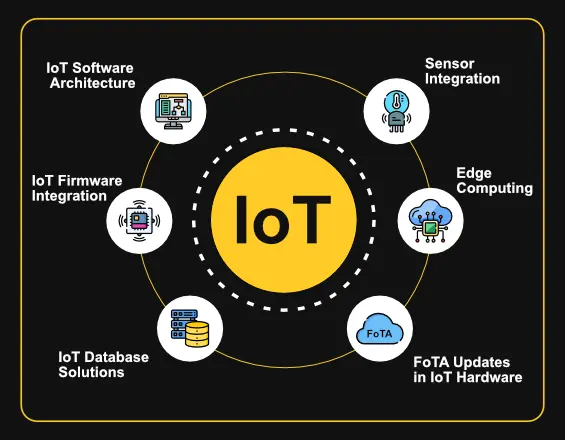

Custom Build Embedded Hardware Devices

We custom-build the devices and as a part of the IoT hardware design and development, we provide IoT software architecture, IoT firmware integration, IoT database solutions, sensor integration, edge computing,FoTA Updates in IoT hardware and custom IoT platform development. Our experience and knowledge have allowed us to always stay abreast of technological innovation with ultra-modern developments that use the most advanced technologies in embedded hardware design.

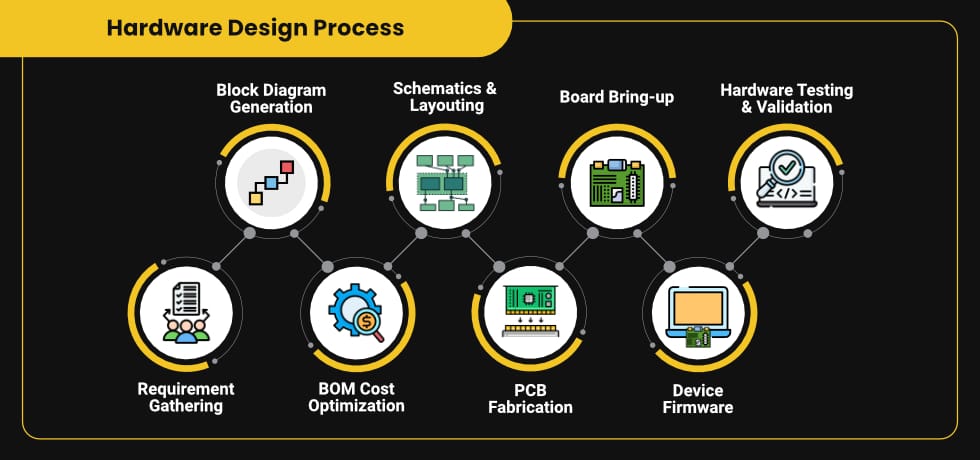

PsiBorg Embedded Hardware Design And Development

- A Block Diagram of all the sections needed to attain the required functionality of the project. Noting how many input/output ports are required and the communication interfaces.

- Memory and power requirements are analysed.

- After the hardware requirements it’s time to know about the software architecture and requirements as they greatly affect hardware.By this stage, major components and technology stack required is selected.

PCB Fabrication And Assembly

- Generation of Gerber File .Submitting Manufacturing data to PCB manufacturers.

- Fabrication of PCB and Assembly of Components.

- Optimization of BoM Cost and Finalization of schematic and Pcb layout.

Unit Testing of PCB And Hardware Validation Testing

- Quality Analysis of manufactured PCB as well as Unit Testing of PCBs.

- The test such as stress testing, defects identification, individual components testing is performed for the product.

- This also includes validation testing of Hardware is done with backend and server. The reports are carefully watched and the bugs and errors , if found any, are resolved.

- After correction the Hardware is set for Bulk production.

Interested? Let’s Get Started

STEP 1

Contact Us

Reach out to us via the contact form or give us a call to initiate the conversation about your IoT development needs.

STEP 2

Get Consultation

Schedule a consultation with our experts to discuss your project in detail, aligning our approach with your unique vision.

STEP 3

Get a Cost Estimate

Receive a detailed cost estimate tailored to your project’s scope and requirements, ensuring transparency in your investment.

STEP 4

Project Kickoff

Once finalized, we'll initiate the project kickoff, marking the beginning of our collaborative journey toward successful IoT product development.

Why Choose PsiBorg?

Ready to elevate your IoT devices with advanced hardware design solutions? Contact us today to discuss your project requirements and explore the possibilities.

Industry-Leading IoT Expertise

With almost a decade of rich experience in IoT technology, we provide tailored services to various industries. Our team strives to deliver innovative and effective solutions that guarantee brilliant connectivity and automation.

End-to-End IoT Solutions – From Concept to Deployment

From the initial idea to launching your IoT project and providing continuous support, we take care of it all. You can completely focus on your business while we ensure a hassle-free experience for our clients.

Secure and Scalable Architecture

We guarantee you scalable, reliable and future-proof solutions. They are designed to provide operational efficiency, strong security, reduce downtime and align with your evolving needs.

Customized IoT Solutions for Diverse Industries

Trust us to offer tailored IoT applications that perfectly align with your specific industry requirements and deliver smart, efficient, and cost-effective solutions.

Got problem worth solving or some amazing idea? Share with us!

Once you let us know your requirement, our technical expert will schedule a call and discuss your idea in detail post sign of an NDA.

All information will be kept confidential.

Speak with an expert

- Get help evaluating if PsiBorg is right partner for you

- Get information on IoT Solution and pricing

- Get a demo of how IoT can help with your use case

IoT Development Solutions for Every Industry

As one of the IoT product development companies, we deliver IoT products that are designed for performance, security, and longevity.

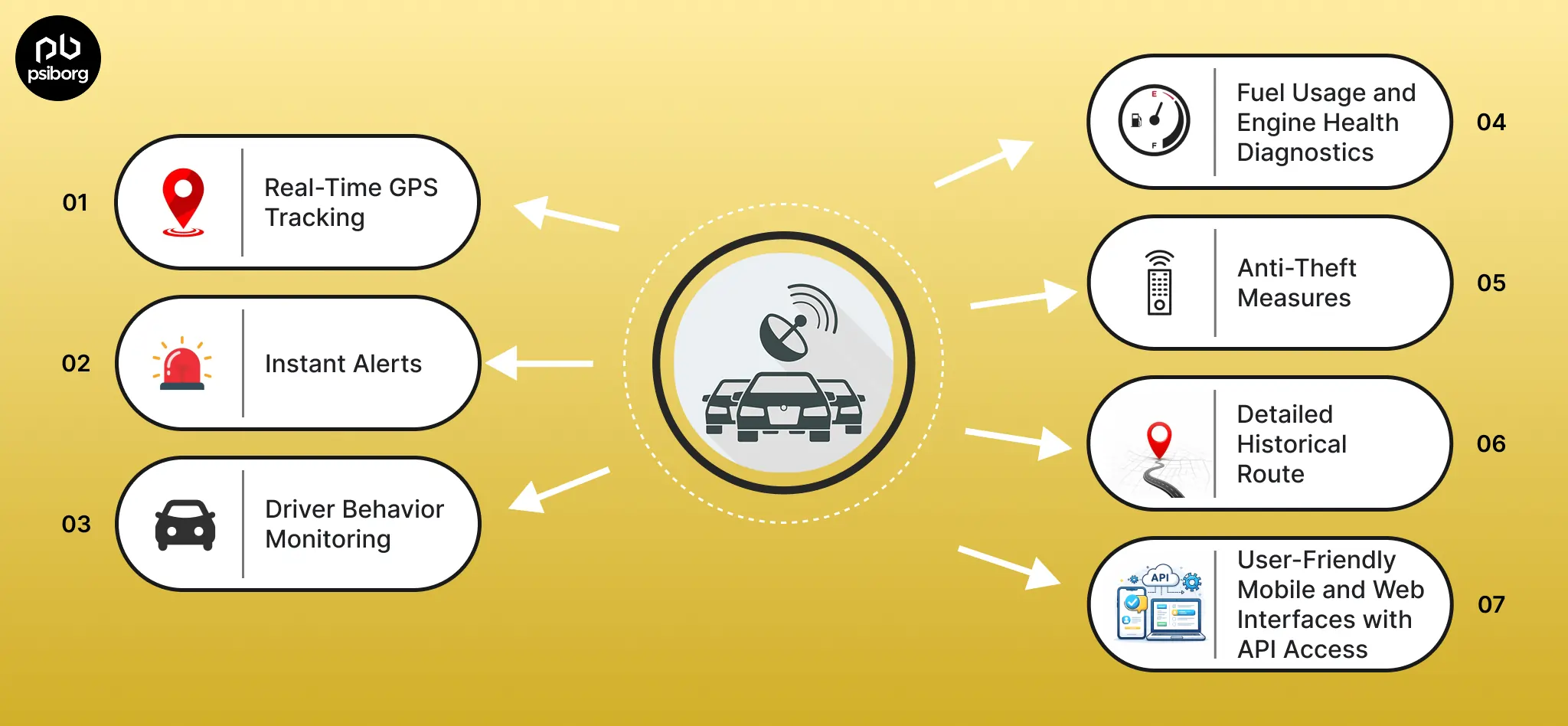

Automotive Industry: Manpower and Asset Tracking

For monitoring workforce productivity and efficiently managing valuable assets in the automotive sector, we build reliable IoT-based tracking solutions.

Mining Industry: Deployed Temperature and Humidity Monitoring

Our highly efficient IoT solutions help mining companies learn about the environmental conditions, ensure safety and comply with industry regulations.

Defence: Deployed Shipment Tracking Solution

To provide security and reliability in the defense sector, we provide real-time tracking solutions that help closely monitor the movement of all critical shipments.

Research and Development Sector: Cattle Health Monitoring System

Researchers and farmers can track cattle health, improve productivity and detect diseases early with our IoT-enabled livestock monitoring systems.

Consumer Electronics: SoS and Emergency Devices

Our IoT app development company provides efficient SoS and emergency devices that help in monitoring emergencies in real time and ensure quick responses and better safety.

Case Studies

The true success of a business lies in the trust and partnership cultivated between clients and the company. Click to read about some of our proudest achievements.

Frequently Asked Question

An embedded hardware is the hardware part used in embedded systems. The embedded hardware includes all the physical devices such as sensors, actuators, registers, ICs, etc.

The embedded hardware development comes with numerous challenges including MCU choice, technology, power optimization, security, etc. Read more about embedded hardware challenges at

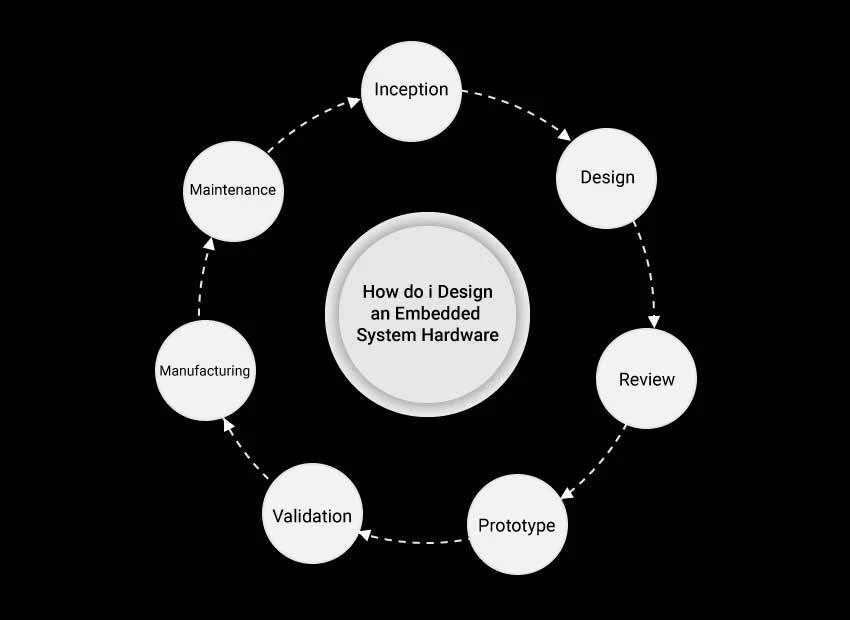

- Inception: Understanding, Gathering, and realizing the possibility.

- Design: Transformation of the idea into a circuit design.

- Review: Reviewing the circuit design and functionality at every point.

- Prototype: Building a Proof of Concept

- Testing and Validation: Testing the prototype and validating it with the customer.

- Manufacturing: Fabrication of the Printed Circuit Board and it’s Assembly.

- Maintenance: Product lifetime support

Embedded hardware design can be a tedious job. The material used for designing and development of embedded hardware is based on the functionalities of the system.